In advanced material research, a multi-zone tube furnace is a critical instrument used to precisely manipulate thermal conditions for developing new materials. It is essential for simulating industrial production processes, synthesizing thin films and powders, and understanding how specific temperature profiles influence the final properties of ceramics, metals, and glasses. Key applications include sintering, annealing, chemical vapor deposition (CVD), and crystal growth.

The primary value of a multi-zone furnace lies not just in its ability to reach high temperatures, but in its power to create and hold specific thermal gradients along the length of the process tube. This precise zonal control allows researchers to move beyond simple heating and actively engineer the thermal environment required for complex material synthesis and analysis.

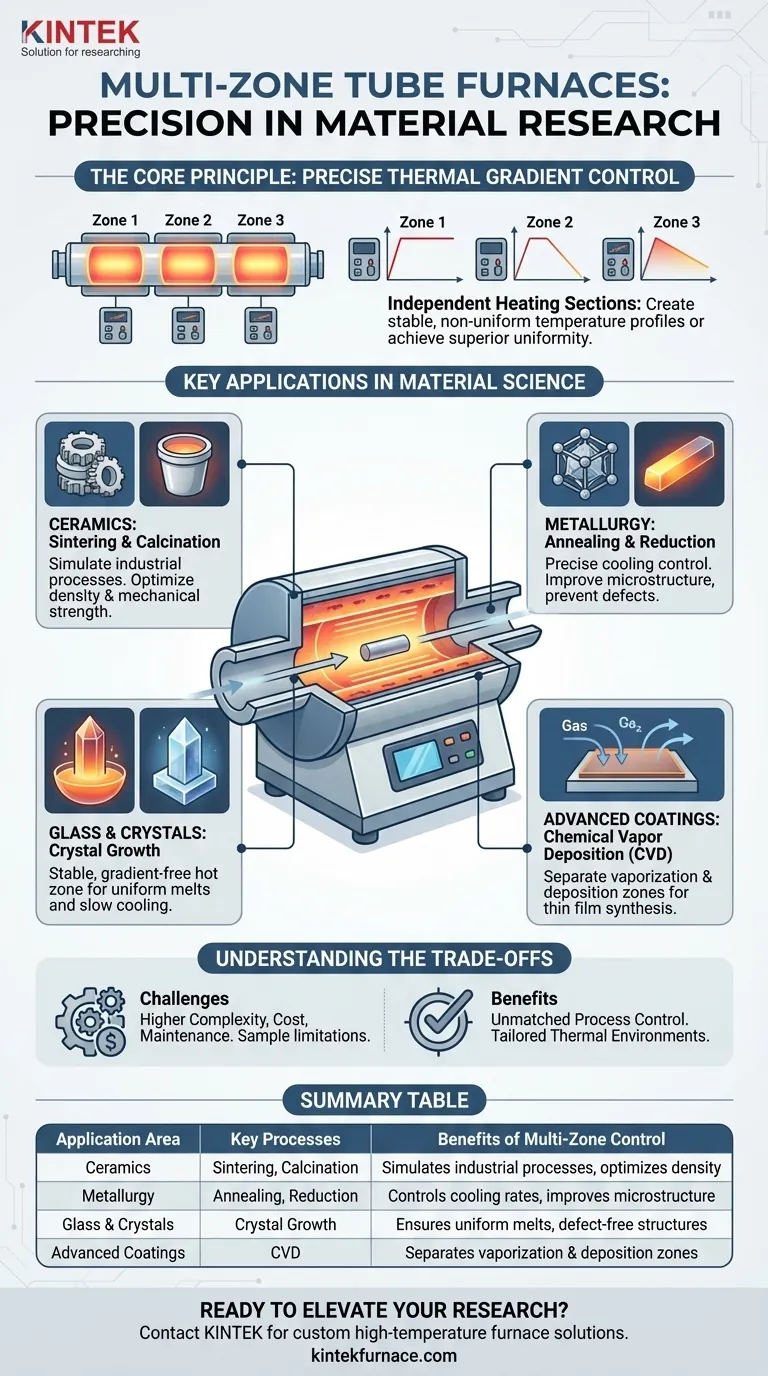

The Core Principle: Precise Thermal Gradient Control

The defining feature of a multi-zone furnace is its division of the heated chamber into multiple, independently controlled heating sections or "zones." This design provides a level of process control that single-zone furnaces cannot match.

What is a Multi-Zone Furnace?

A multi-zone tube furnace has at least two, and often three or more, separate heating elements and corresponding temperature controllers. Each zone can be programmed to a different temperature, allowing the user to create a stable, non-uniform temperature profile along the sample.

Why Temperature Gradients Matter

The ability to create a deliberate temperature gradient is essential for many advanced processes. For example, in chemical vapor deposition (CVD), one zone can be used to heat a substrate while another, hotter zone vaporizes a chemical precursor upstream. The gas then flows to the cooler substrate, where it deposits as a thin film.

This same principle is vital for crystal growth, where a carefully controlled temperature change is necessary to initiate and sustain the growth process from a melt or vapor.

Achieving True Temperature Uniformity

Paradoxically, multiple zones are also the best way to achieve a perfectly uniform temperature over a long area. In any furnace, heat is lost at the ends of the tube. By setting the outer zones to a slightly higher temperature, you can compensate for this heat loss and create a much longer, flatter, and more stable central hot zone than is possible with a single heating element.

Key Applications in Material Science

The ability to precisely tailor a thermal profile makes multi-zone furnaces indispensable across several research fields.

For Ceramics: Sintering and Calcination

In ceramics, sintering is the process of using heat to fuse powders into a solid, dense object. A multi-zone furnace allows researchers to accurately simulate industrial belt furnace conditions, with zones for pre-heating, high-temperature soaking, and controlled cooling. This helps optimize the final density and mechanical strength of a ceramic component.

For Metallurgy: Annealing and Reduction

Annealing involves heating and then slowly cooling a metal to relieve internal stresses and improve its ductility. Multiple zones enable extremely precise control over the cooling rate, which is critical for achieving a desired microstructure and preventing defects.

These furnaces are also used for pyrolysis and reduction, where specific temperature zones can facilitate the decomposition of a compound or the extraction of a pure metal from its ore.

For Glass and Crystal Growth

When researching specialty glasses or growing large, single crystals, thermal control is paramount. A multi-zone furnace provides the stable, gradient-free hot zone needed to create a uniform melt, followed by the very slow, controlled cooling required to form a large, defect-free crystalline structure.

For Advanced Coatings: Chemical Vapor Deposition (CVD)

CVD is a cornerstone of modern materials science, used for creating everything from semiconductor films to wear-resistant coatings. Multi-zone furnaces provide the ideal environment by separating the process into distinct thermal regions within a single tube: a vaporization zone for the precursor, a transport zone, and a deposition zone for the substrate.

Understanding the Trade-offs

While powerful, a multi-zone furnace is a more complex instrument with its own set of challenges.

Complexity and Control

Programming and stabilizing multiple independent zones requires more expertise than operating a single-zone unit. Achieving the desired thermal profile often involves an iterative process of measurement and adjustment, as the zones can influence one another.

Cost and Maintenance

Multi-zone furnaces are more expensive to purchase and operate. They contain more heating elements, controllers, and thermocouples, leading to higher potential maintenance costs and more possible points of failure over the lifetime of the instrument.

Sample and Process Limitations

Like all tube furnaces, these are generally limited by the diameter of the process tube. This can restrict sample size, and the horizontal orientation may not be suitable for all powder-based processes where gravity or mixing is a factor, for which a rotary tube furnace might be better suited.

Making the Right Choice for Your Goal

The decision to use a multi-zone furnace should be driven by the specific thermal requirements of your experiment.

- If your primary focus is process simulation or optimization: Use the zones to precisely mimic the heating, soaking, and controlled cooling stages of an industrial process.

- If your primary focus is material synthesis (e.g., CVD): Use different zones to create distinct temperature areas for precursor vaporization and substrate deposition within a single, continuous process.

- If your primary focus is creating highly uniform materials: Use the outer zones to compensate for end-of-tube heat loss, creating a long, exceptionally stable, and uniform central hot zone.

Mastering the thermal profile of a multi-zone furnace gives you direct control over the fundamental properties of your material.

Summary Table:

| Application Area | Key Processes | Benefits of Multi-Zone Control |

|---|---|---|

| Ceramics | Sintering, Calcination | Simulates industrial processes, optimizes density and strength |

| Metallurgy | Annealing, Reduction | Controls cooling rates, improves microstructure, prevents defects |

| Glass & Crystals | Crystal Growth, Glass Formation | Ensures uniform melts, slow cooling for defect-free structures |

| Advanced Coatings | Chemical Vapor Deposition (CVD) | Separates vaporization and deposition zones for thin film synthesis |

Ready to elevate your material research with precise thermal control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Whether you're optimizing sintering, annealing, or CVD processes, our multi-zone tube furnaces can help you achieve superior results. Contact us today to discuss how we can support your research goals!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- How does a multi-zone tube furnace achieve precise temperature gradient control? Master MoS2 Isotope Monolayer Synthesis

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab