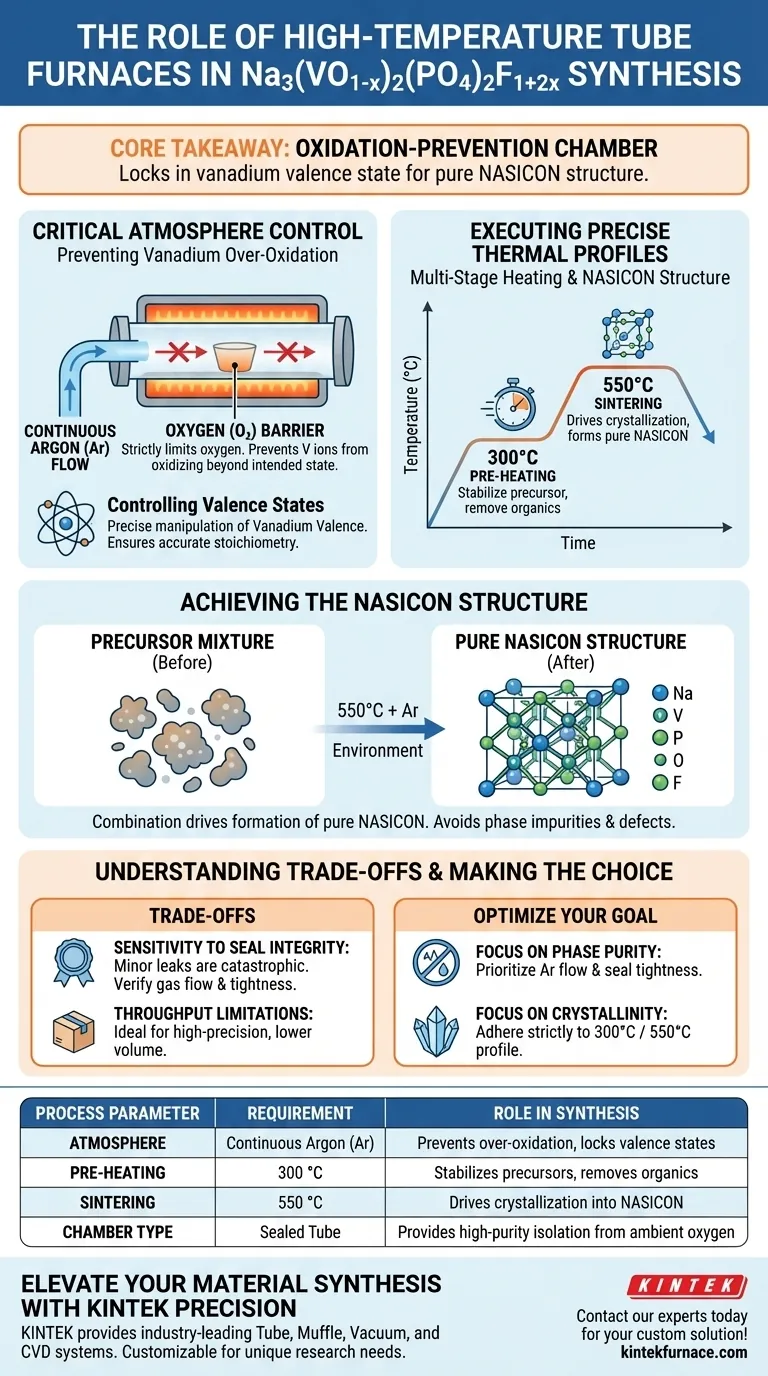

A high-temperature tube furnace serves as the precision environment required to finalize the synthesis of Na3(VO1-x)2(PO4)2F1+2x by providing a strictly controlled inert atmosphere and specific thermal ramping. It executes a dual-stage heating process—pre-heating at 300 °C followed by sintering at 550 °C—under a continuous flow of Argon (Ar) to dictate the material's final chemical and structural state.

Core Takeaway The tube furnace is not merely a heat source; it is an oxidation-prevention chamber that locks in the specific vanadium valence state required to crystallize a pure NASICON structure.

The Critical Role of Atmosphere Control

Preventing Vanadium Over-Oxidation

The primary function of the tube furnace in this context is to act as a barrier against oxygen.

Vanadium ions are highly reactive and sensitive to oxygen at elevated temperatures.

By maintaining a continuous Argon (Ar) inert atmosphere, the furnace strictly limits oxygen levels, preventing the vanadium from oxidizing beyond the intended state.

Controlling Valence States

The electrical and structural properties of the final material depend heavily on the specific valence state of the metal ions.

The inert environment allows for precise manipulation of the vanadium valence state.

This control is essential for ensuring the stoichiometry of the compound remains accurate during the high-energy sintering phase.

Executing Precise Thermal Profiles

The Necessity of Multi-Stage Heating

The tube furnace is utilized to execute a specific, multi-step thermal recipe rather than a simple ramp-to-peak.

The process involves pre-heating at 300 °C, likely to stabilize the precursor or remove residual organics, followed by sintering at 550 °C.

This staged approach ensures that intermediate reactions occur in the correct sequence before the final structure is formed.

Achieving the NASICON Structure

The ultimate goal of this thermal treatment is crystallization.

The combination of the 550 °C sintering temperature and the oxygen-free environment drives the formation of the pure NASICON structure.

Without this precise thermal and atmospheric combination, the material would likely suffer from phase impurities or structural defects.

Understanding the Trade-offs

Sensitivity to Seal Integrity

The effectiveness of a tube furnace is entirely dependent on the integrity of its seals.

Even a minor leak in the flanges can introduce trace amounts of oxygen, which is catastrophic for vanadium-based compounds.

Operators must diligently verify gas flow and seal tightness, as the furnace provides no protection if the inert barrier is breached.

Throughput Limitations

Tube furnaces offer superior atmosphere control but generally have lower volume capacities compared to box furnaces.

This makes them ideal for high-precision, high-purity synthesis where quality outweighs quantity.

However, scaling this process for mass production often requires significant changes to equipment or methodology.

Making the Right Choice for Your Goal

To optimize the synthesis of Na3(VO1-x)2(PO4)2F1+2x, align your equipment usage with your specific processing needs:

- If your primary focus is Phase Purity: Prioritize the integrity of the Argon flow and seal tightness to prevent any deviation in the vanadium valence state.

- If your primary focus is Crystallinity: Ensure your thermal profile strictly adheres to the 300 °C pre-heat and 550 °C sintering schedule to achieve the correct NASICON structure.

The tube furnace determines the success of this synthesis by coupling thermal energy with strict atmospheric isolation.

Summary Table:

| Process Parameter | Requirement | Role in Synthesis |

|---|---|---|

| Atmosphere | Continuous Argon (Ar) | Prevents vanadium over-oxidation & locks valence states |

| Pre-heating | 300 °C | Stabilizes precursors and removes residual organics |

| Sintering | 550 °C | Drives crystallization into the pure NASICON structure |

| Chamber Type | Sealed Tube | Provides high-purity isolation from ambient oxygen |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect NASICON structure requires absolute atmospheric integrity and thermal accuracy. KINTEK provides industry-leading Tube, Muffle, Vacuum, and CVD systems specifically designed for sensitive chemical synthesis.

Backed by expert R&D and world-class manufacturing, our high-temperature furnaces are fully customizable to meet your unique research or production needs. Whether you are controlling vanadium valence states or scaling up complex powders, KINTEK ensures your materials reach their peak performance.

Ready to optimize your thermal processing? Contact our experts today to find your custom solution!

Visual Guide

References

- Oskar Grabowski, A. Czerwiński. Solution-combustion synthesis of Na3(VO1-x)2(PO4)2F1+2x as a positive electrode material for sodium-ion batteries. DOI: 10.1038/s44172-025-00471-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of introducing high-purity nitrogen into a tube furnace? Optimize Bone Pyrolysis & Biochar Yield

- What is the specific function of a high-temperature tube furnace for MXene-NiCo2Se4? Master the Selenization Process

- What process environment does a drop-tube furnace system provide? Expert Simulated Waste Incineration Research

- What is the primary function of a quartz tube diffusion furnace? Optimize PERT Solar Cell Doping Performance

- What role does a high-temperature quartz tube furnace play in CMSM production? Master Carbonization Precision

- What are the main industrial applications of rotary tube furnaces? Boost Efficiency in Metallurgy and Materials Processing

- What is the primary function of a high-temperature tube furnace in two-stage pyrolysis? Precision Thermal Control

- What is the purpose of using a resistance-heated tube furnace with inert gas? Protect Steel Integrity Today