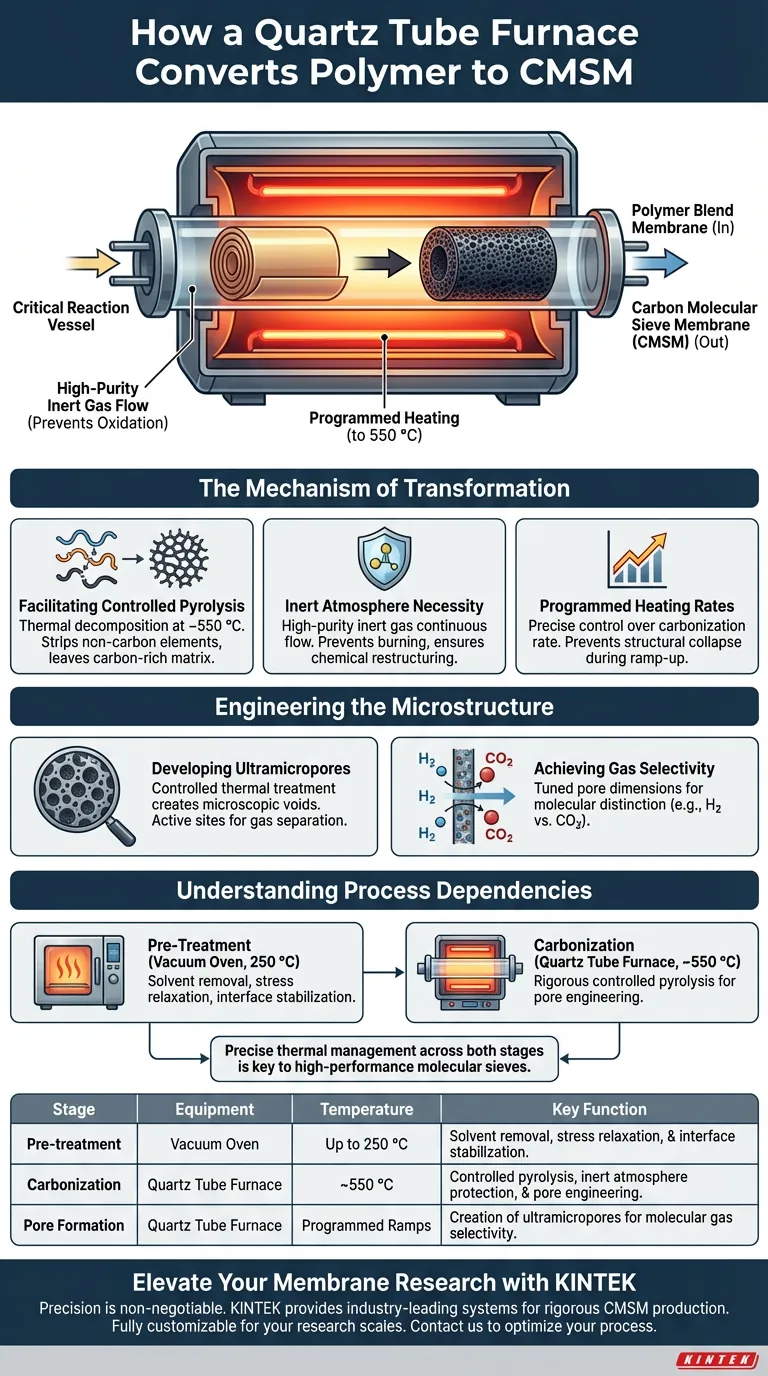

The high-temperature quartz tube furnace serves as the critical reaction vessel for carbonization. It provides a strictly controlled thermal environment and a high-purity inert gas atmosphere, which are essential for transforming polymer blend membranes into Carbon Molecular Sieve Membranes (CMSMs). Through a programmed heating process typically reaching 550 °C, the furnace executes a precise pyrolysis reaction that converts organic polymer chains into a rigid carbon framework.

The furnace’s primary function is to facilitate controlled pyrolysis, replacing the organic polymer structure with an ultramicroporous carbon framework capable of distinguishing between specific gas molecules.

The Mechanism of Transformation

Facilitating Controlled Pyrolysis

The core operation performed by the furnace is pyrolysis. By subjecting the polymer to temperatures around 550 °C, the furnace initiates the thermal decomposition of the organic material. This process strips away non-carbon elements, leaving behind a carbon-rich matrix.

The Necessity of Inert Atmosphere

A high-quality quartz tube furnace maintains a continuous flow of high-purity inert gas. This prevents the polymer from simply burning (oxidizing) at high temperatures. Instead of combustion, the material undergoes a chemical restructuring in a protected environment.

Programmed Heating Rates

Success relies on more than just reaching a peak temperature; it requires getting there at a specific speed. The furnace’s programmed heating functionality allows for precise control over the carbonization rate. This controlled ramp-up prevents the structural collapse that could occur if the polymer were heated too rapidly.

Engineering the Microstructure

Developing Ultramicropores

The ultimate goal of using this specific furnace is to engineer the pore size of the final membrane. The controlled thermal treatment creates ultramicroporous structures within the carbon material. These microscopic voids are the active sites where gas separation occurs.

Achieving Gas Selectivity

Because the furnace allows for such fine control over the carbonization environment, the resulting pores can be tuned to specific dimensions. This precision enables the membrane to distinguish between gas molecules effectively, such as separating hydrogen from carbon dioxide based on their molecular size.

Understanding Process Dependencies

The Role of Pre-Treatment

While the quartz tube furnace handles the high-intensity conversion, it relies on a "morphological foundation" established earlier. Before entering the furnace, membranes undergo high-temperature annealing in a vacuum oven at temperatures up to 250 °C.

Managing Solvents and Stress

The furnace is not designed to handle significant solvent removal or stress relaxation. The pre-treatment phase ensures trace residual solvents are removed and internal stresses from film-forming are eliminated. This transitions the polymer chains to a thermodynamically stable state before the rigorous carbonization begins.

Ensuring Interface Stability

If the pre-treatment is neglected, the compatibilizers at the polymer interfaces may not function effectively. The quartz tube furnace solidifies the structure, but the initial stability of the polymer blend must be established beforehand to ensure a defect-free final carbon membrane.

Making the Right Choice for Your Goal

If your primary focus is Pore Size Precision: Prioritize the programming capabilities of the quartz tube furnace to fine-tune the heating rate and peak temperature (around 550 °C) for exact ultramicropore formation.

If your primary focus is Structural Integrity: Ensure the precursor membrane has been thoroughly annealed in a vacuum oven at 250 °C to remove solvents and stress before it ever enters the quartz furnace.

Precise thermal management across both annealing and carbonization is the difference between a simple charred film and a high-performance molecular sieve.

Summary Table:

| Stage | Equipment | Temperature | Key Function |

|---|---|---|---|

| Pre-treatment | Vacuum Oven | Up to 250 °C | Solvent removal, stress relaxation, & interface stabilization. |

| Carbonization | Quartz Tube Furnace | ~550 °C | Controlled pyrolysis, inert atmosphere protection, & pore engineering. |

| Pore Formation | Quartz Tube Furnace | Programmed Ramps | Creation of ultramicropores for molecular gas selectivity. |

Elevate Your Membrane Research with KINTEK

Precision is non-negotiable when engineering ultramicroporous structures for gas separation. KINTEK provides industry-leading Tube, Muffle, Vacuum, and CVD systems specifically designed to handle the rigorous programmed heating and high-purity atmosphere requirements of CMSM production.

Backed by expert R&D and manufacturing, our high-temperature furnaces are fully customizable to meet your unique research or production scales. Contact us today to discover how KINTEK’s advanced thermal solutions can optimize your carbonization process and ensure superior structural integrity for your materials.

Visual Guide

References

- Chamaal Karunaweera, John P. Ferraris. Carbon–Carbon Composite Membranes Derived from Small-Molecule-Compatibilized Immiscible PBI/6FDA-DAM-DABA Polymer Blends. DOI: 10.3390/separations11040108

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the benefits of a horizontal tube furnace? Achieve Precise Thermal Control and Versatility

- What is the primary role of a Tube Furnace in g-C3N4 synthesis? Achieve Precise Thermal Polycondensation

- What are the specific functions of a vertical alumina tube reactor? Key Roles in Gasification Kinetics Research

- What does the horizontal orientation refer to in tube furnaces? Discover Its Benefits and Applications

- What is the difference between a tube furnace and a muffle furnace? Choose the Right High-Temp Solution

- What is an atmosphere tube furnace? Unlock Precise High-Temperature Processing

- What are the disadvantages of resistance heating tube furnaces? Slow Heating, Uneven Temperatures, Low Efficiency

- Why is a controlled atmosphere tube furnace essential for YBCO? Master Oxygen Stoichiometry for Superconductivity