In essence, the primary benefits of a horizontal tube furnace are its exceptional ease of use, predictable temperature uniformity, and operational versatility. The horizontal orientation allows for simple placement and manipulation of samples, while the design provides a consistent heating zone that is critical for obtaining reliable results in both laboratory research and industrial processes.

The true value of a horizontal tube furnace is not just its ability to get hot, but its combination of simplicity and control. It provides an accessible, uniform thermal environment that serves as a foundational tool for a vast range of scientific and manufacturing applications.

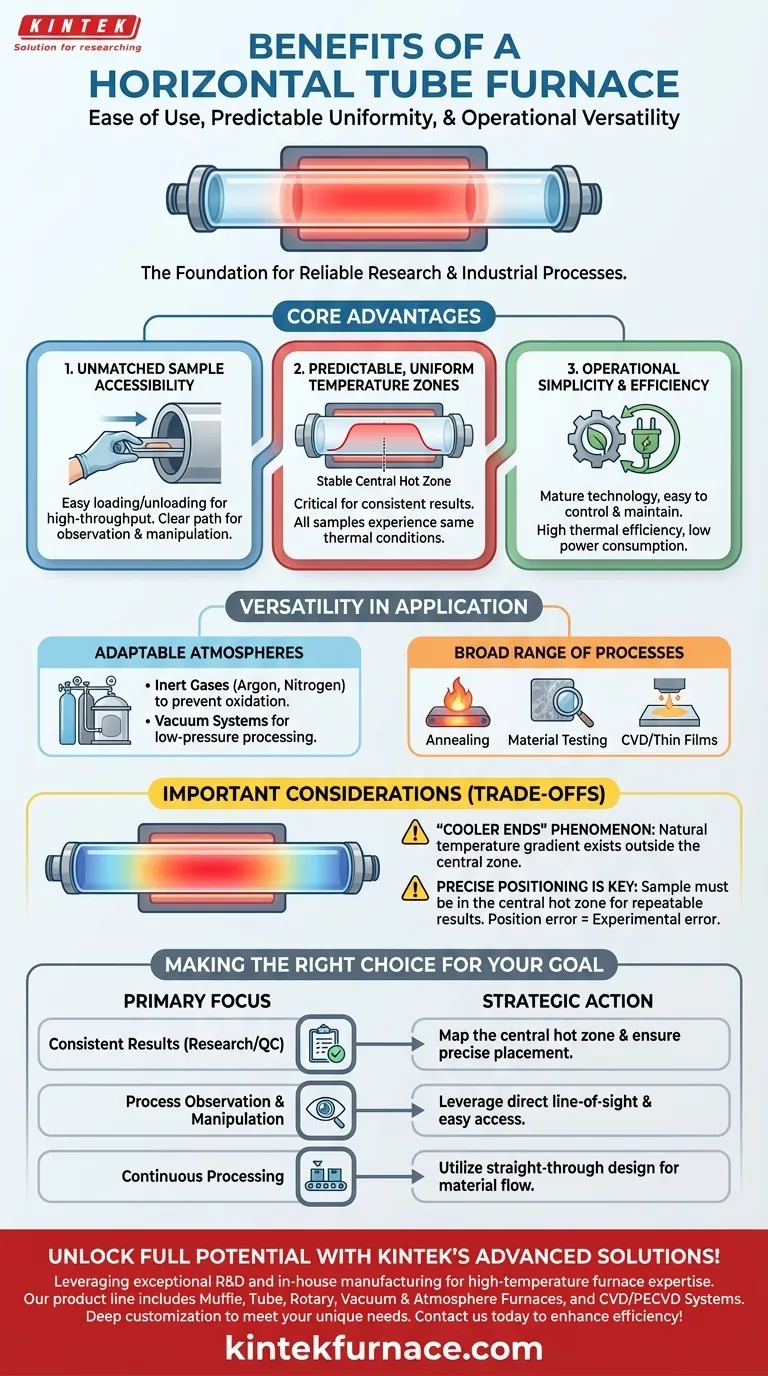

The Core Advantages of a Horizontal Design

The horizontal configuration is the most common for a reason. It offers a blend of accessibility, thermal performance, and operational simplicity that makes it a laboratory workhorse.

Unmatched Sample Accessibility

The horizontal layout allows you to easily slide boats, crucibles, or substrates into and out of the heating chamber. This is invaluable for high-throughput testing.

This orientation is also ideal for processes that require observation or direct manipulation of the sample during the heating cycle, as the sample path is clear and unobstructed.

Predictable, Uniform Temperature Zones

While the entire tube length will have a temperature gradient, horizontal furnaces are engineered to produce a highly uniform and stable temperature zone in the center.

This uniformity is the key to consistent results, ensuring that all parts of a sample experience the same thermal conditions. This is non-negotiable for applications like material property testing, quality control, and chemical synthesis.

Operational Simplicity and Efficiency

Horizontal tube furnaces benefit from mature technology and a straightforward structure, making them easy to operate, control, and maintain.

They generally offer high thermal efficiency with relatively low power consumption, as the heating elements are positioned for direct radiation to the process tube.

Versatility in Application

Beyond its basic design, the horizontal tube furnace is a highly adaptable platform. It can be configured to meet the specific demands of many different processes.

Adaptable Atmospheres

The sealed nature of the process tube makes it simple to control the internal atmosphere. You can easily introduce inert gases like argon or nitrogen to prevent oxidation.

Similarly, these furnaces can be connected to a vacuum system to perform heating cycles in a low-pressure environment, which is critical for certain material processing and purification tasks.

Broad Range of Processes

This versatility makes horizontal furnaces suitable for a wide array of applications. Common uses include annealing to relieve material stress, material testing under specific thermal profiles, and chemical vapor deposition (CVD) for creating thin films.

Understanding the Trade-offs

No piece of equipment is perfect for every task. Understanding the inherent characteristics of a horizontal tube furnace is key to using it effectively.

The "Cooler Ends" Phenomenon

A horizontal tube furnace will naturally be cooler at the ends of the tube than it is in the center. This temperature gradient is a physical reality of the design.

While multi-zone furnaces can extend the length of the uniform zone, you must always be aware that true temperature uniformity only exists within a specific central portion of the tube.

Sample Positioning is Key

Because of this temperature gradient, precise sample placement is critical. For results to be repeatable, the sample must be placed in the same position within the central hot zone for every run.

Failing to control for position is a common source of error that can compromise the validity of an experiment or the quality of a production batch.

Making the Right Choice for Your Goal

To leverage a horizontal tube furnace effectively, align its strengths with your primary objective.

- If your primary focus is consistent results for research or QC: Your priority is to map the furnace's central hot zone and ensure your samples are always placed within it.

- If your primary focus is process observation or manipulation: The horizontal design provides the direct line-of-sight and easy access you need to interact with the sample during heating.

- If your primary focus is continuous processing: The straight-through design is ideal for applications where a material is slowly pulled or pushed through the heating zone.

Its combination of accessibility and controlled heating makes the horizontal tube furnace a fundamental and indispensable tool for thermal processing.

Summary Table:

| Benefit | Description |

|---|---|

| Sample Accessibility | Easy sliding of samples in/out for high-throughput and manipulation during heating. |

| Temperature Uniformity | Stable, uniform central hot zone ensures consistent thermal conditions for reliable results. |

| Operational Simplicity | Straightforward design for easy use, control, and maintenance with high thermal efficiency. |

| Application Versatility | Supports various processes like annealing, material testing, and CVD with adaptable atmospheres. |

Unlock the full potential of your thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace expertise. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our tailored furnace solutions can enhance your efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide