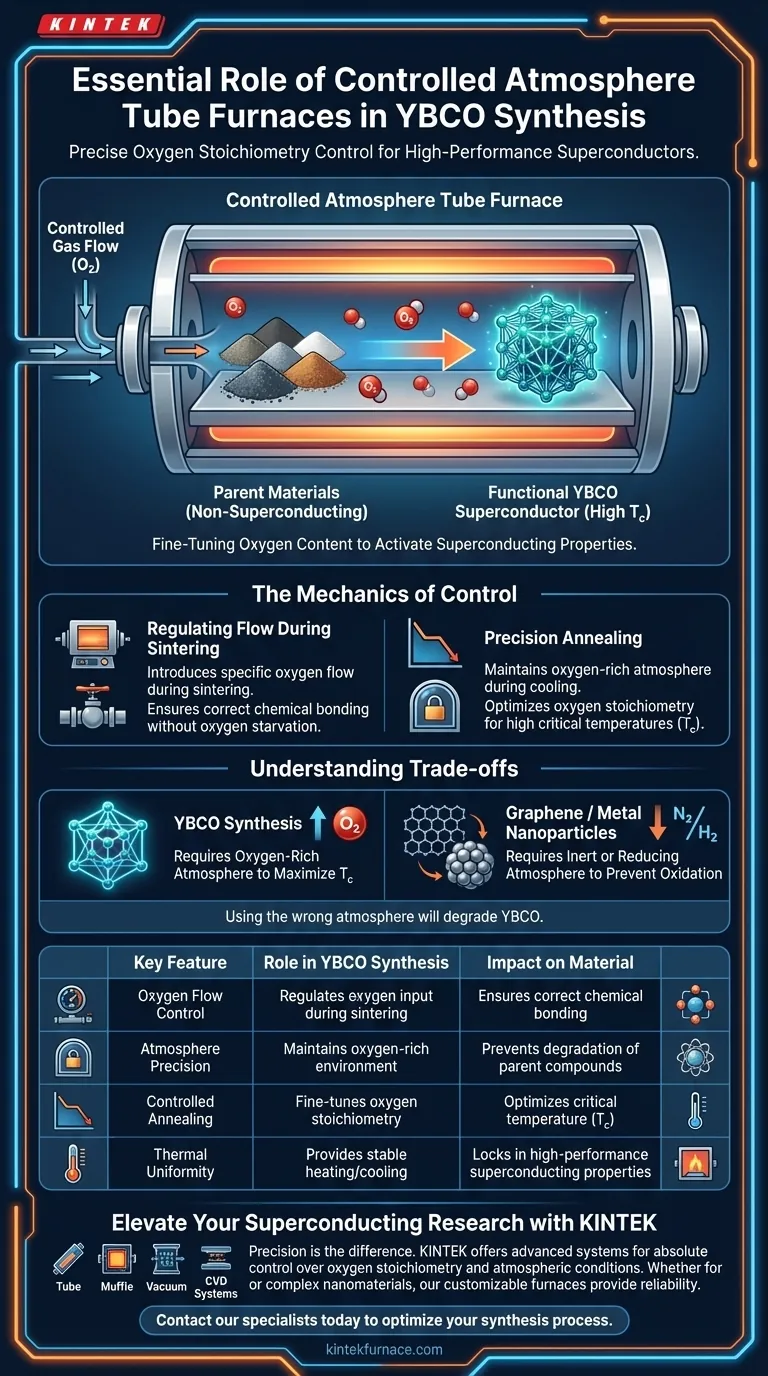

The essential role of a controlled atmosphere tube furnace lies in its ability to precisely dictate oxygen stoichiometry. YBCO (Yttrium Barium Copper Oxide) is not inherently a high-performance superconductor; its capabilities are strictly dependent on achieving specific oxygen levels. This furnace provides the necessary environment to regulate oxygen flow during the critical heating stages of synthesis.

The difference between a standard ceramic and a high-performance superconductor often rests entirely on oxygen content. A controlled atmosphere tube furnace allows you to fine-tune this variable, transforming non-superconducting parent materials into functional superconductors.

The Critical Link Between Oxygen and Performance

Oxygen Stoichiometry

The superconducting performance of YBCO is highly sensitive to its chemical composition. Specifically, the material's oxygen content is the defining variable that determines its critical temperature ($T_c$).

Transforming Parent Materials

Raw materials for YBCO are often non-superconducting "parent" compounds. To activate superconducting properties, you must alter their chemical structure. This requires an environment where oxygen can be introduced into the crystal lattice with high precision.

The Mechanics of Control

Regulating Flow During Sintering

Standard heating in air is often insufficient for advanced YBCO synthesis. A controlled atmosphere furnace allows researchers to introduce a specific oxygen flow during the sintering phase. This ensures the material bonds correctly without starving for oxygen.

Precision Annealing

The annealing stage is where the final properties of the superconductor are locked in. By maintaining a specific oxygen-rich atmosphere during this cooling phase, researchers can optimize the oxygen stoichiometry. This optimization is strictly necessary to achieve high critical temperatures.

Understanding the Trade-offs

Atmosphere Specificity

It is vital to understand that "controlled atmosphere" does not always mean "oxygen-rich." While other materials like graphene or metal nanoparticles require inert or reducing atmospheres to prevent oxidation, YBCO requires the opposite. Using the wrong atmospheric setting will degrade the YBCO rather than synthesize it.

Complexity vs. Results

Using a controlled atmosphere tube furnace adds complexity compared to a standard air kiln. It requires managing gas flows and monitoring pressure. However, this added complexity is the unavoidable cost of achieving the high-performance characteristics required for superconductivity.

Making the Right Choice for Your Goal

To ensure your synthesis yields the desired material properties, align your equipment usage with your chemical requirements:

- If your primary focus is YBCO synthesis: You must prioritize a furnace capable of precise oxygen flow regulation during annealing to maximize the critical temperature.

- If your primary focus is Carbon-based materials (e.g., Graphene): You should utilize a reducing atmosphere to prevent oxidation, distinct from the requirements of YBCO.

- If your primary focus is Metal Nanoparticles: You require an inert atmosphere to stabilize the material during formation.

Mastering the atmosphere is the final step in mastering the material.

Summary Table:

| Key Feature | Role in YBCO Synthesis | Impact on Material |

|---|---|---|

| Oxygen Flow Control | Regulates oxygen input during sintering | Ensures correct chemical bonding |

| Atmosphere Precision | Maintains oxygen-rich environment | Prevents degradation of parent compounds |

| Controlled Annealing | Fine-tunes oxygen stoichiometry | Optimizes critical temperature (Tc) |

| Thermal Uniformity | Provides stable heating/cooling | Locks in high-performance superconducting properties |

Elevate Your Superconducting Research with KINTEK

Precision is the difference between a simple ceramic and a high-performance superconductor. Backed by expert R&D and manufacturing, KINTEK offers advanced Tube, Muffle, Vacuum, and CVD systems designed to give you absolute control over oxygen stoichiometry and atmospheric conditions. Whether you are synthesizing YBCO or developing complex nanomaterials, our customizable high-temperature furnaces provide the reliability your lab requires.

Ready to optimize your synthesis process? Contact our specialists today to find the perfect furnace solution for your unique research needs.

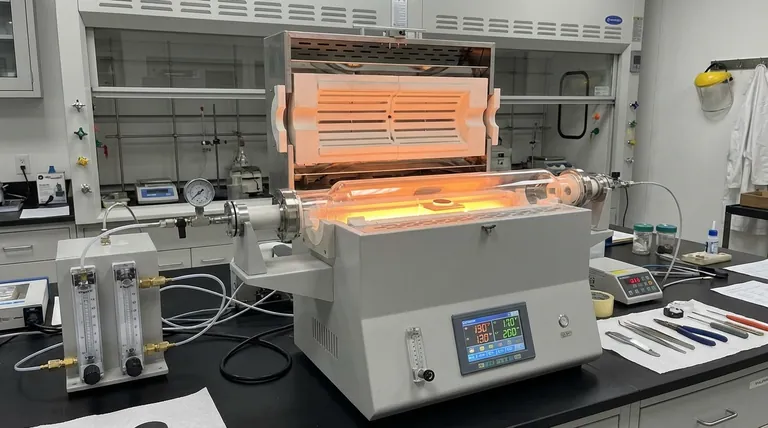

Visual Guide

References

- T. Chattopadhyay. Superconductivity in High-Temperature Materials. DOI: 10.36948/ijfmr.2025.v07i05.55511

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the differences between solid tube and split type tube furnaces? Choose the Right Furnace for Your Lab

- What role does a tube furnace play in the physical synthesis of metal nanoparticles? Master Phase Transformation

- What role does a laboratory tube furnace play in the carbonization process of porous carbon particles? Expert Insights

- What is the role of a high-temperature tube furnace in the preparation of TiO2-alpha-Ga2O3 heterostructures?

- What are the standard and customizable options for tube furnaces? Find the Perfect Fit for Your Lab's Needs

- What is a tube furnace and how is it designed? Achieve Precise, Uniform Heating for Your Lab

- What is a split tube furnace and what makes it versatile? Unlock Easy Access and Flexibility for Your Lab

- What factors determine the selection of a three-zone split tube furnace? Key Specs for Precision Thermal Processing