In short, selecting a three-zone split tube furnace is determined by five core factors: your maximum required temperature, the physical dimensions of your sample and process tube, the level of temperature uniformity or gradient you need to achieve, your requirements for atmosphere control, and the sophistication of the control system. These factors are not independent; they are dictated entirely by the specific thermal process you intend to run.

The selection process is less about the furnace itself and more about precisely defining your application. A furnace is a tool, and the right choice is the one that gives you the most precise, repeatable, and safe control over your specific thermal processing environment.

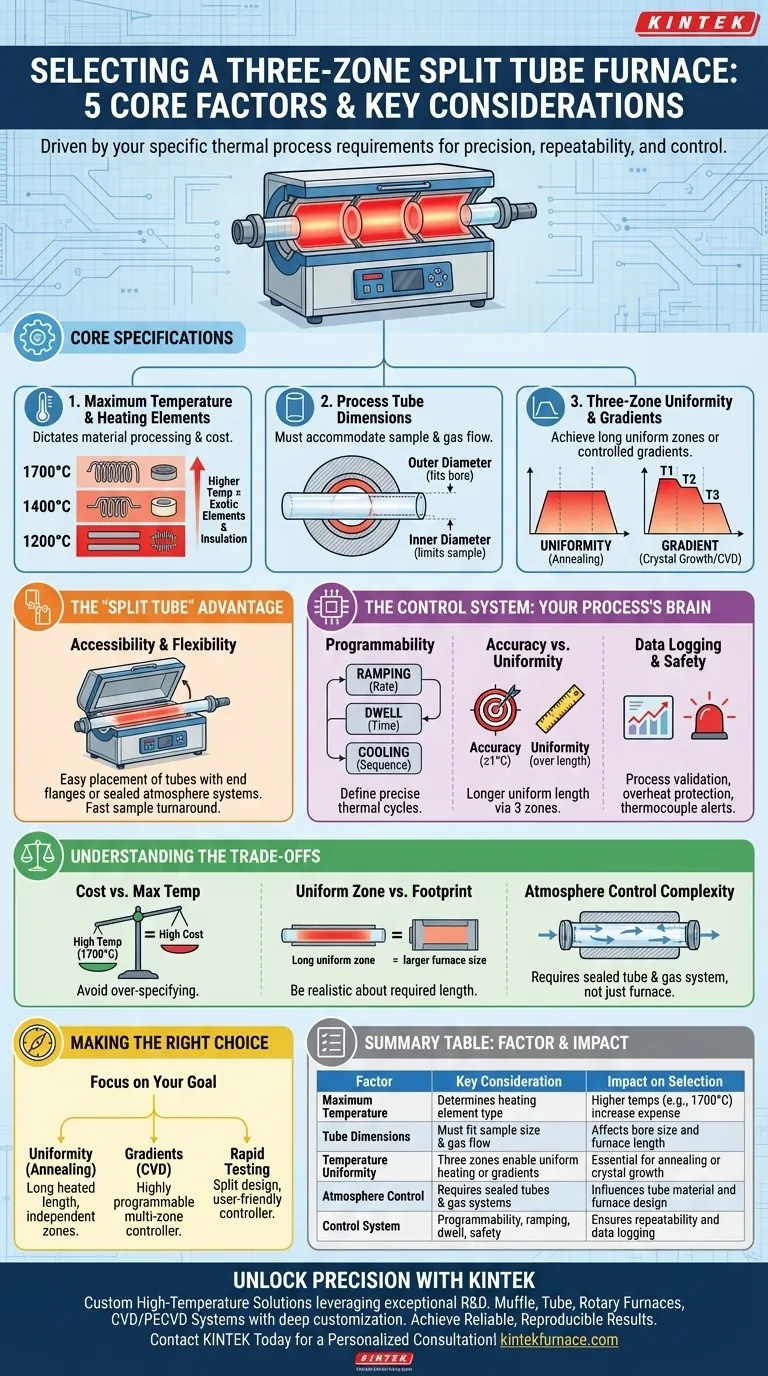

Deconstructing the Core Specifications

The foundation of your choice rests on matching the furnace's physical and thermal capabilities to the demands of your material and process.

Maximum Temperature and Heating Elements

The single most important factor is the maximum operating temperature. This dictates the types of materials you can process and directly influences furnace cost.

Common temperature tiers are 1200°C, 1400°C, and 1700°C, which correspond to different heating element materials. Higher temperatures require more exotic and expensive elements and insulation.

Process Tube Dimensions (Diameter and Length)

The furnace must accommodate your process tube. The outer diameter of your tube must fit within the furnace's bore.

The internal diameter of your tube, in turn, limits the size of your samples. It also impacts gas flow dynamics for processes requiring atmosphere control.

The "Three-Zone" Advantage: Uniformity and Gradients

A single-zone furnace is hottest in the middle and cooler at the ends. A three-zone furnace uses two additional end zones to compensate for this natural heat loss.

This allows you to create a significantly longer, highly uniform temperature zone across the furnace's length, which is critical for processes like annealing.

Alternatively, you can program the zones to different setpoints to create a controlled and stable temperature gradient, essential for applications like chemical vapor transport or crystal growth.

The "Split Tube" Advantage: Accessibility

The "split tube" design means the furnace hinges open, allowing for the easy placement and removal of the process tube.

This is a critical feature when working with tubes that have end flanges or are part of a sealed atmosphere control system, as it avoids having to feed the entire assembly through a solid tube.

The Control System: Your Process's Brain

A furnace is only as good as its controller. This is what gives you the power to execute a precise and repeatable thermal cycle.

Programmability, Ramping, and Dwell

Modern controllers allow you to program multiple steps in a heating profile. You can define the rate of temperature change (ramping), the time spent at a target temperature (dwell), and the cooling sequence.

Temperature Accuracy vs. Uniformity

Accuracy (e.g., ±1°C) refers to how close a zone's temperature is to its setpoint. Uniformity refers to how consistent the temperature is over a specified length of the tube.

A three-zone furnace is chosen specifically to achieve superior temperature uniformity over a longer length compared to a single-zone model.

Data Logging and Safety

For process validation and quality control, the ability to log temperature data over time is invaluable.

Crucial safety features, such as overheat protection and alarms for thermocouple failure, are non-negotiable for protecting your experiment, your lab, and your personnel.

Understanding the Trade-offs

Every furnace specification involves a compromise. Being aware of these trade-offs is key to making a practical, cost-effective decision.

Cost vs. Maximum Temperature

The cost of a furnace escalates significantly with its maximum temperature rating. Do not over-specify; choosing a 1700°C furnace when your process only requires 1100°C is an unnecessary expense in both initial cost and energy consumption.

Uniform Zone Length vs. Furnace Footprint

Achieving a long uniform hot zone requires an even longer total heated length. Be realistic about the required uniform length for your samples to avoid purchasing an unnecessarily large and power-hungry furnace.

Atmosphere Control Complexity

Running a process under an inert or reducing atmosphere is not a feature of the furnace alone. It requires a high-purity, often quartz, process tube with sealed end flanges, as well as a gas flow control system. The furnace simply provides the heat.

Making the Right Choice for Your Application

Filter your options by focusing on the primary goal of your thermal process.

- If your primary focus is creating a large, uniform temperature zone (e.g., for annealing): Prioritize a model with a long heated length, independent zone control, and specifications that guarantee the uniformity you need over that length.

- If your primary focus is growing crystals or creating a gradient (e.g., for CVD): You need a highly programmable, multi-zone controller that allows you to precisely set and maintain different temperatures in each zone.

- If your primary focus is rapid, flexible sample testing: The "split tube" design is your key feature for fast sample turnaround, paired with a user-friendly controller for simple, repeatable programs.

Ultimately, a well-specified furnace is the foundation for reliable, reproducible, and insightful results.

Summary Table:

| Factor | Key Consideration | Impact on Selection |

|---|---|---|

| Maximum Temperature | Determines heating element type and cost | Higher temps (e.g., 1700°C) increase expense |

| Tube Dimensions | Must fit sample size and gas flow needs | Affects bore size and furnace length |

| Temperature Uniformity | Three zones enable uniform heating or gradients | Essential for annealing or crystal growth |

| Atmosphere Control | Requires sealed tubes and gas systems | Influences tube material and furnace design |

| Control System | Programmability for ramping, dwell, and safety | Ensures repeatability and data logging |

Unlock Precision in Your Lab with KINTEK's Custom High-Temperature Solutions

Struggling to find the perfect furnace for your unique thermal processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your experimental requirements.

Whether you're focused on annealing, crystal growth, or rapid testing, our three-zone split tube furnaces offer superior temperature control, uniformity, and accessibility. Let us help you achieve reliable, reproducible results—contact us today for a personalized consultation and elevate your laboratory's efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing