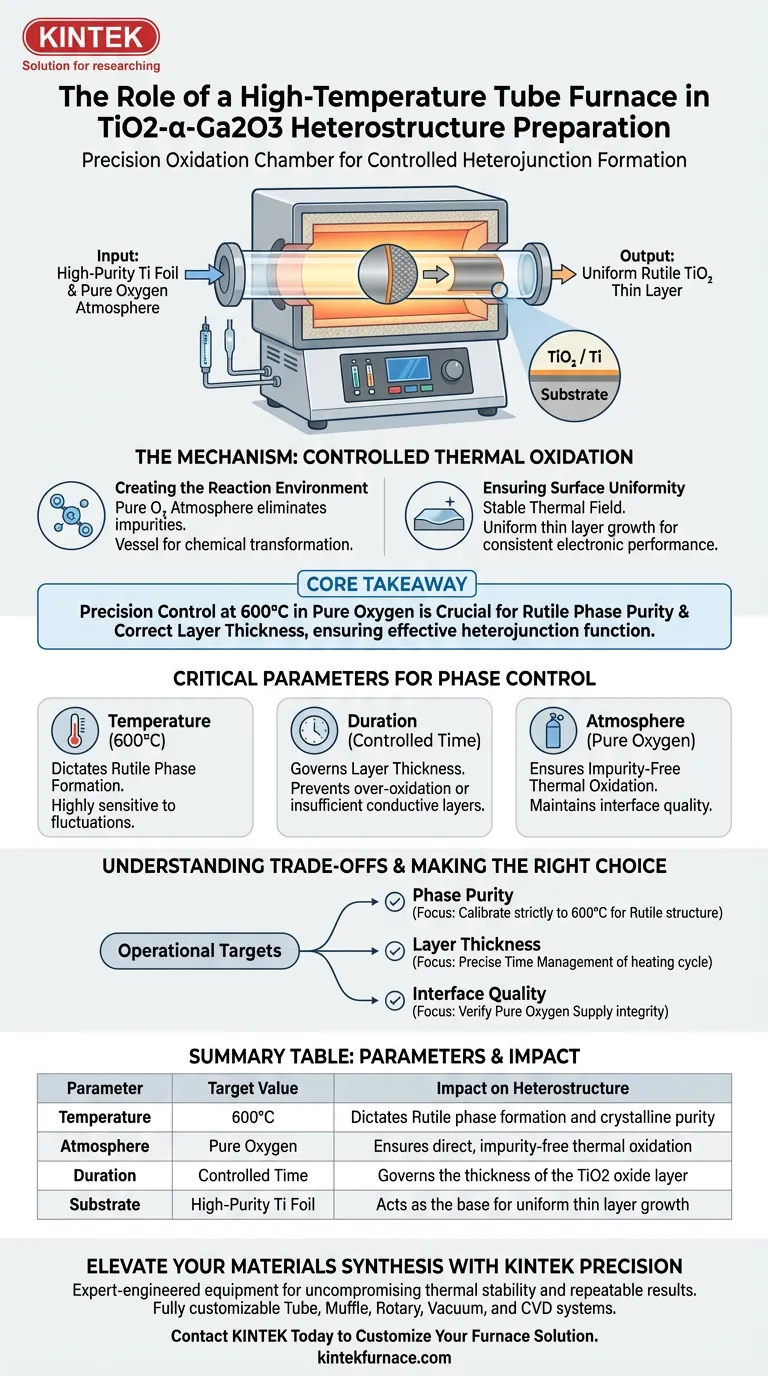

In the preparation of TiO2-alpha-Ga2O3 heterostructures, the high-temperature tube furnace serves as a precision oxidation chamber. Its primary function is to facilitate the controlled thermal oxidation of high-purity titanium foil within a pure oxygen atmosphere. This process transforms the surface of the foil into a uniform Titanium Dioxide (TiO2) thin layer, which is essential for forming the heterojunction.

Core Takeaway The tube furnace provides the requisite stability to maintain a constant temperature of 600°C in a pure oxygen environment. This precise control is the deciding factor in growing a TiO2 layer with the correct crystalline phase (rutile) and thickness, ensuring the material functions effectively as both a heterojunction component and a conductive layer.

The Mechanism: Controlled Thermal Oxidation

Creating the Reaction Environment

The furnace acts as a vessel for chemical transformation rather than simple heating. By introducing a pure oxygen atmosphere, the furnace enables the direct oxidation of high-purity titanium foil. This eliminates environmental impurities that could degrade the quality of the interface.

Ensuring Surface Uniformity

The stability of the thermal field within the tube allows the TiO2 layer to grow evenly across the titanium substrate. A uniform thin layer is critical for consistent electronic performance across the entire heterostructure.

Critical Parameters for Phase Control

The Role of Temperature

Temperature is not merely a catalyst; it dictates the material's final phase. The process typically requires a precise setting of 600 degrees Celsius. Maintaining this specific temperature is necessary to achieve the rutile phase of TiO2, which is preferred for this specific heterostructure application.

The Impact of Duration

Alongside temperature, the time spent within the high-temperature zone determines the layer's physical properties. Precise time control governs the thickness of the oxide layer. If the layer is too thick or too thin, it may fail to act as an effective conductive layer for subsequent performance testing.

Understanding the Trade-offs

Sensitivity to Fluctuations

While the tube furnace provides stability, the process is highly sensitive to deviations. A fluctuation in the thermal gradient or oxygen purity can lead to mixed phases (e.g., unintended anatase formation) or uneven oxide growth, drastically reducing the quality of the heterojunction.

Process Isolation

Unlike vacuum annealing furnaces used for cleaning interfaces in other 2D materials, this process is additive (oxidation). Consequently, strict control must be maintained to prevent over-oxidation, which could consume too much of the underlying titanium foil or create a brittle interface.

Making the Right Choice for Your Goal

To optimize the preparation of TiO2-alpha-Ga2O3 heterostructures, focus on these specific operational targets:

- If your primary focus is Phase Purity: Ensure the furnace is calibrated strictly to 600°C, as deviations will alter the crystalline structure away from the desired rutile phase.

- If your primary focus is Layer Thickness: Prioritize precise time management of the heating cycle to control the depth of oxidation on the titanium foil.

- If your primary focus is Interface Quality: Verify the integrity of the pure oxygen supply to prevent contaminants from interfering with the uniform formation of the TiO2 layer.

Success in this synthesis relies not just on high heat, but on the precise stability of the thermal and chemical environment.

Summary Table:

| Parameter | Target Value | Impact on Heterostructure |

|---|---|---|

| Temperature | 600°C | Dictates Rutile phase formation and crystalline purity |

| Atmosphere | Pure Oxygen | Ensures direct, impurity-free thermal oxidation |

| Duration | Controlled Time | Governs the thickness of the TiO2 oxide layer |

| Substrate | High-Purity Ti Foil | Acts as the base for uniform thin layer growth |

Elevate Your Materials Synthesis with KINTEK Precision

Achieving the perfect rutile phase and layer uniformity in TiO2-alpha-Ga2O3 heterostructures requires the uncompromising thermal stability that only expert-engineered equipment can provide. Backed by industry-leading R&D and manufacturing, KINTEK offers a comprehensive range of Tube, Muffle, Rotary, Vacuum, and CVD systems.

Our lab high-temperature furnaces are fully customizable to meet your unique research needs, ensuring precise phase control and repeatable results for your most demanding applications. Partner with us to bring world-class precision to your laboratory.

Contact KINTEK Today to Customize Your Furnace Solution

Visual Guide

References

- Wenxing Zhang, Wanjun Li. A Facile Synthesis of TiO2–α-Ga2O3-Based Self-Powered Broad-Band UVC/UVA Photodetector and Optical Communication Study. DOI: 10.3390/ma17164103

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What factors influence the heating process in a tube furnace? Master Temperature Control and Efficiency

- What are the advantages of using a laboratory tube furnace for BCZT ceramics? Boost Piezoelectric d33 by up to 41%

- What is the purpose of the gas circulation system in a tube furnace? Control Chemical Atmospheres for Precise High-Temperature Processing

- What is the function of a multi-zone tube furnace in CVD synthesis? Master 2D In2Se3 Nanosheet Precision

- How does a three-zone tube furnace facilitate the synthesis of germanium nanowires? Achieve High-Quality SVG Results

- What is the primary function of a Drop Tube Furnace? Master Single-Particle Solid Fuel Ignition Analysis

- What makes the multi gradient experimental tube furnace capable of creating temperature gradients? Unlock Precise Thermal Control for Your Experiments

- What materials are commonly used for the reaction tubes in a tube furnace? Choose the Best for Your Thermal Process