The primary function of a Drop Tube Furnace (DTF) is to replicate the extreme thermal environment of industrial burners within a controlled laboratory setting. By utilizing a vertical tube structure, it allows researchers to drop individual solid fuel particles through a constant high-temperature zone, enabling the precise observation of their behavior from initial heating to complete ignition.

By isolating single particles in a gravity-fed environment, the Drop Tube Furnace removes external variables found in bulk combustion. This allows for an accurate analysis of how specific atmospheric compositions and temperatures drive the volatile evolution and ignition process.

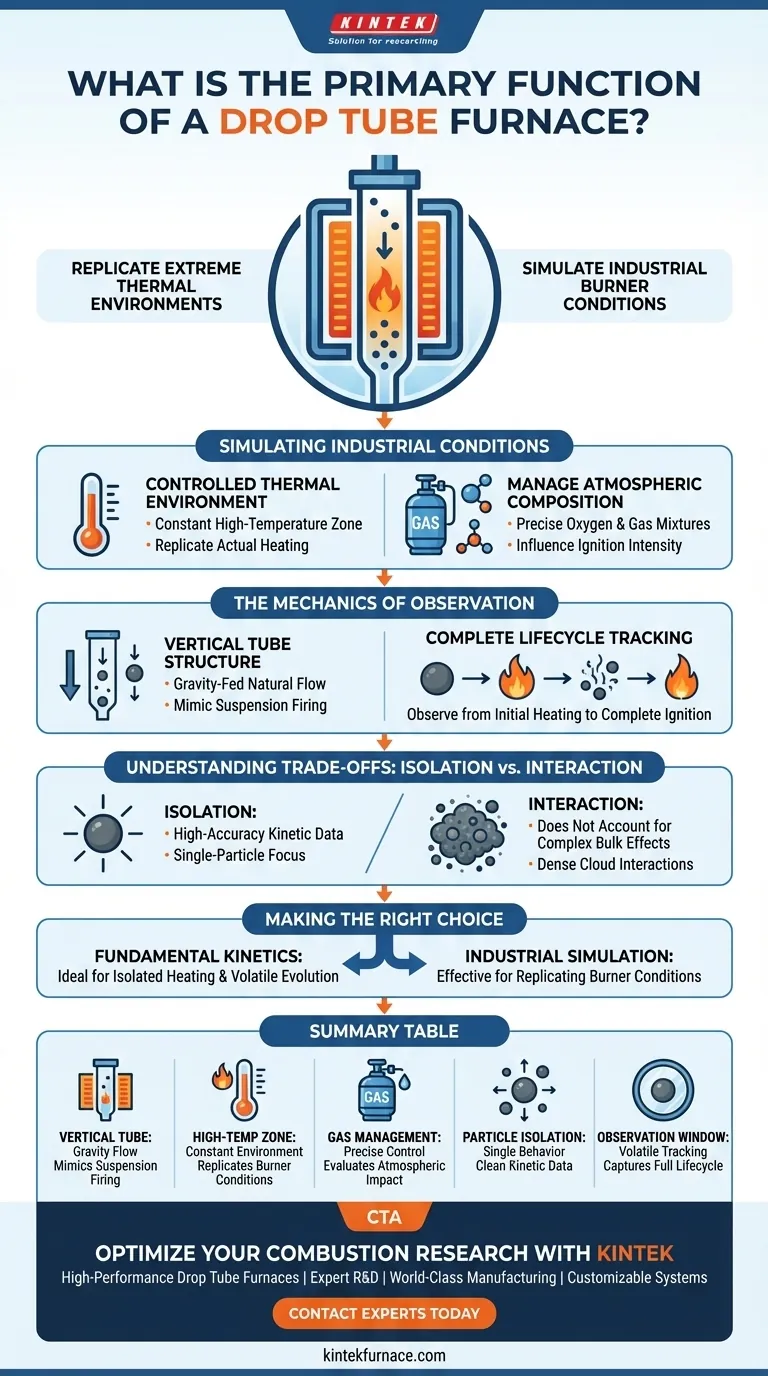

Simulating Industrial Conditions

Creating a Controlled Thermal Environment

To understand how fuel will behave in a real-world power plant or engine, you must replicate the heat without the chaos of a full-scale system.

The Drop Tube Furnace provides a constant high-temperature environment. This consistency is critical for simulating the actual heating conditions found in industrial burners, ensuring that the data collected is relevant to real-world applications.

Managing Atmospheric Composition

Combustion does not happen in a vacuum; it is dictated by the surrounding gases.

The DTF allows researchers to introduce a specific atmospheric composition into the tube. This capability enables the study of how different oxygen levels or gas mixtures influence the speed and intensity of ignition.

The Mechanics of Observation

Utilizing Gravity for Natural Flow

The defining physical feature of this apparatus is its vertical tube structure.

Solid particles are allowed to fall freely under the influence of gravity. This mimics the suspension firing methods often used in industry, where fuel is injected and burned while suspended in air.

Tracking the Complete Lifecycle

The primary goal of the DTF is not just to see if fuel burns, but to see how it burns.

Because the environment is so controlled, researchers can perform a precise observation of the entire sequence. This includes the initial heating of the particle, the volatile evolution (release of gases), and finally, the complete ignition process.

Understanding the Trade-offs

Isolation vs. Interaction

While the Drop Tube Furnace is excellent for characterizing individual fuel particles, this strength is also a limitation.

By focusing on single-particle ignition, the apparatus intentionally removes the interactions that occur between particles in a dense fuel cloud. Therefore, while it provides highly accurate kinetic data for a single unit of fuel, it does not account for the complex particle-to-particle effects found in a dense industrial fuel bed.

Making the Right Choice for Your Research

If you are designing an experiment to characterize solid fuel, consider the following based on the specific capabilities of a Drop Tube Furnace:

- If your primary focus is fundamental kinetics: The DTF is ideal because it isolates the heating and volatile evolution of single particles, providing clean data free from interference.

- If your primary focus is industrial simulation: The DTF is effective because it replicates the constant high-temperature and gravity-driven flow of actual burners, validating how fuel will perform under stress.

Ultimately, the Drop Tube Furnace serves as the critical link between theoretical fuel chemistry and practical industrial combustion.

Summary Table:

| Feature | Function in DTF | Research Benefit |

|---|---|---|

| Vertical Tube Structure | Uses gravity for natural particle flow | Mimics industrial suspension firing methods |

| High-Temp Zone | Maintains constant thermal environment | Replicates extreme burner conditions precisely |

| Gas Management | Precise control of atmospheric composition | Evaluates impact of oxygen/gas levels on ignition |

| Particle Isolation | Focuses on single-particle behavior | Provides clean kinetic data without bulk interference |

| Observation Window | Tracks volatile evolution & ignition | Captures the full lifecycle of solid fuel combustion |

Optimize Your Combustion Research with KINTEK

Precision in fuel characterization starts with the right equipment. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Drop Tube Furnaces, Muffle, Tube, and Vacuum systems tailored for your lab's most demanding thermal processing needs. Whether you are analyzing fundamental kinetics or simulating industrial burners, our customizable systems provide the constant temperature control and atmospheric precision necessary for groundbreaking results.

Ready to elevate your lab's capabilities? Contact our experts today to discuss your unique project requirements and discover how KINTEK's advanced heating solutions can drive your research forward.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What function does a tube furnace serve in converting electrospun fibers into CNFs? Mastering the Carbonization Path

- How does a high-temperature heating furnace utilize solid precursors in the synthesis of MoS2? Mastering TMD Growth

- How do furnace chamber working conditions influence the choice of a tube furnace? Optimize Performance and Cost

- What environmental applications do rotary tube furnaces have? Transform Waste into Value with Advanced Thermal Processing

- What are some examples of applications for three-zone tube furnaces in advanced materials processing? Unlock Precision Thermal Control for Your Lab

- What is the function of a tube furnace in catalyst annealing? Unlock L10 Ordered Structures for Peak Performance

- Why is annealing in a tube furnace essential for rGO-NiO-ZnO-400? Optimize Your Catalyst Synthesis