A tube or atmospheric furnace functions as a precision reactor that facilitates the chemical conversion of electrospun polymer fibers into carbon nanofibers (CNFs) through a strictly controlled two-step thermal process. By managing both temperature and gas atmosphere, the furnace first stabilizes the fiber structure in air and subsequently converts it into a highly conductive carbon matrix under an inert nitrogen environment.

The furnace is not merely a heater; it serves as the critical reaction chamber where a thermoplastic polymer is chemically restructured into a heat-resistant, conductive carbon lattice without losing its original nanofibrous morphology.

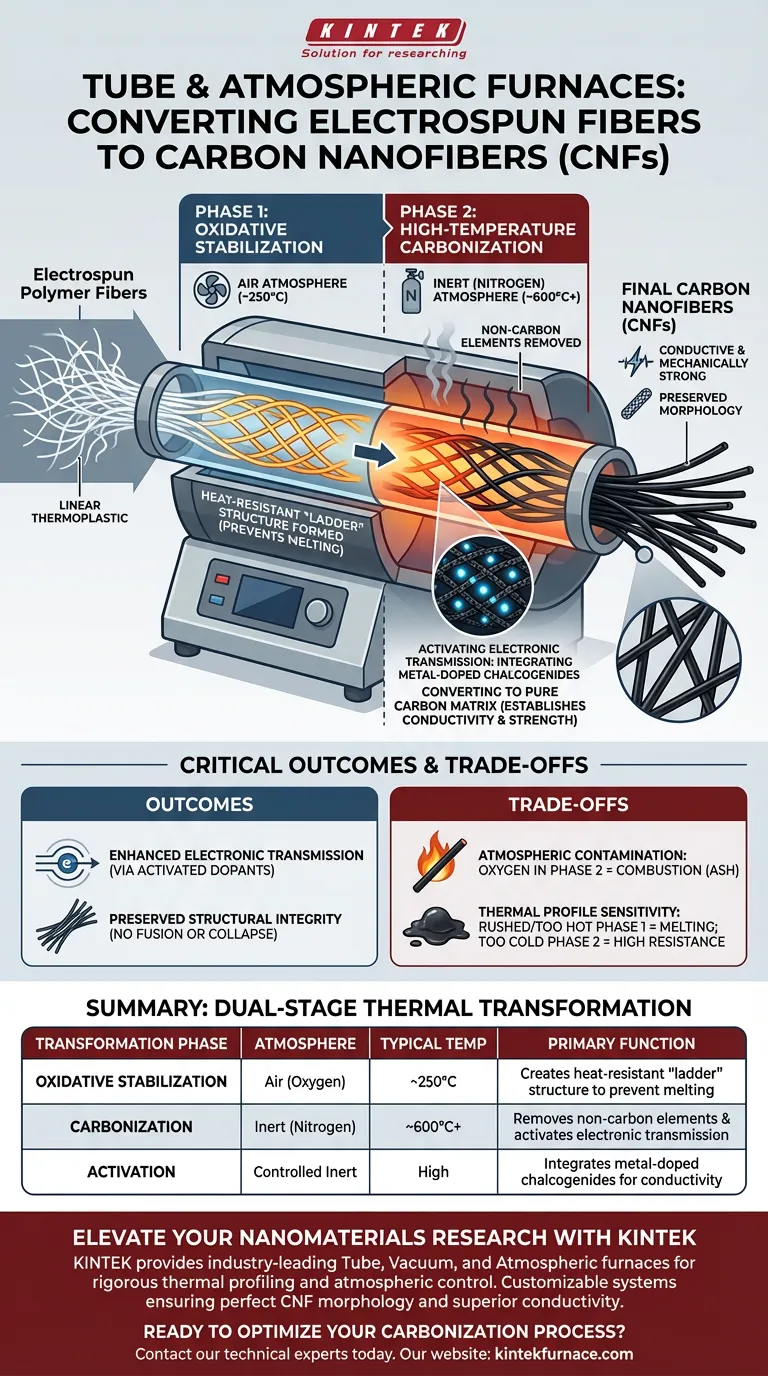

The Dual-Stage Thermal Transformation

To convert a polymer carrier into a functional carbon nanofiber, the material must undergo radical chemical changes without physically collapsing. The furnace orchestrates this through two distinct phases.

Phase 1: Oxidative Stabilization

The first function of the furnace is to heat the fibers in an air environment. This process typically occurs at lower temperatures (conceptually similar to the 250°C range often found in stabilization-specific equipment).

During this stage, the furnace facilitates oxidation reactions that transform the polymer from a linear thermoplastic into a heat-resistant "ladder" structure. This step is non-negotiable; without it, the fibers would simply melt and lose their shape during the subsequent high-heat phase.

Phase 2: High-Temperature Carbonization

Once stabilized, the furnace environment is switched to a continuous nitrogen atmosphere. The temperature is raised significantly, typically to around 600°C.

In this inert environment, the non-carbon elements are driven off, converting the remaining material into a pure carbon matrix. This step is responsible for establishing the material's electrical conductivity and final mechanical strength.

Critical Material Outcomes

Beyond simple heating, the furnace ensures specific internal properties are activated within the nanofibers.

Activating Electronic Transmission

The high-temperature carbonization phase does more than just char the plastic. It activates internal components, specifically metal-doped chalcogenides, embedded within the fibers.

The controlled thermal environment ensures these dopants are properly integrated into the carbon matrix. This integration allows for superior electronic transmission, making the final CNF suitable for advanced electronic applications.

Preserving Structural Integrity

The primary challenge in CNF production is keeping the fiber distinct and intact. The furnace's precise temperature ramping prevents thermal shock.

By carefully controlling the transition from stabilization to carbonization, the furnace ensures the fibers do not fuse together or collapse, maintaining the high surface area characteristic of electrospun materials.

Understanding the Trade-offs

While the furnace is the engine of conversion, improper management of the atmospheric conditions leads to catastrophic failure.

The Risk of Atmospheric Contamination

The distinction between the air and nitrogen phases is critical. Introducing oxygen during the high-temperature carbonization phase (600°C) will cause the carbon to combust, turning your fibers into ash rather than CNFs.

Thermal Profile Sensitivity

If the initial stabilization phase is rushed or the temperature is too high, the fibers will fail to form the necessary ladder structure.

This results in the fibers melting into a blob before they can carbonize. Conversely, if the carbonization temperature is too low, the material will retain too much electrical resistance, failing to achieve the conductivity required for electronic applications.

Making the Right Choice for Your Goal

The specific settings you employ in the furnace depend heavily on the desired properties of your final carbon nanofibers.

- If your primary focus is Electrical Conductivity: Ensure your furnace creates a pure Nitrogen environment at 600°C to maximize carbon purity and activate metal-doped chalcogenides.

- If your primary focus is Fiber Morphology: Prioritize the initial oxidative stabilization phase in air to lock in the physical structure before high-heat treatment.

Success relies on using the furnace to balance the chemical need for oxidation (stabilization) against the physical need for inert protection (carbonization).

Summary Table:

| Transformation Phase | Atmosphere | Typical Temp | Primary Function |

|---|---|---|---|

| Oxidative Stabilization | Air (Oxygen) | ~250°C | Creates heat-resistant 'ladder' structure to prevent melting |

| Carbonization | Inert (Nitrogen) | ~600°C+ | Removes non-carbon elements and activates electronic transmission |

| Activation | Controlled Inert | High | Integrates metal-doped chalcogenides for conductivity |

Elevate Your Nanomaterials Research with KINTEK

Precision is paramount when converting electrospun fibers into high-performance carbon nanofibers. KINTEK provides industry-leading Tube, Vacuum, and Atmospheric furnaces designed to deliver the rigorous thermal profiling and atmospheric control your research demands.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet unique laboratory needs—ensuring your CNFs maintain perfect morphology and superior conductivity.

Ready to optimize your carbonization process? Contact our technical experts today to find the ideal high-temperature solution for your lab.

Visual Guide

References

- Gamze Çelik Çoğal, Mária Omastová. Electrospun cobalt-doped 2D-MoSe2/polypyrrole hybrid-based carbon nanofibers as electrochemical sensing platforms. DOI: 10.1007/s00604-023-06078-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What conditions does a laboratory tube furnace provide for PtS/Ti3C2Tx preparation? Master 300°C Thermal Decomposition

- What is the necessity of using high-purity argon (Ar) gas in a tube furnace for Sb sulfurization?

- What makes tube furnaces suitable for large-scale production? Unlock Modular Scalability for High-Throughput

- What additional features might a split tube furnace have? Boost Your Lab's Precision and Control

- What metallurgical processes are performed in horizontal furnaces? Unlock Precision Heat Treatment and Sintering

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a high-temperature quartz tube furnace play in CMSM production? Master Carbonization Precision

- How does a drop tube furnace compare to a horizontal tube furnace? Choose the Right Furnace for Your Process