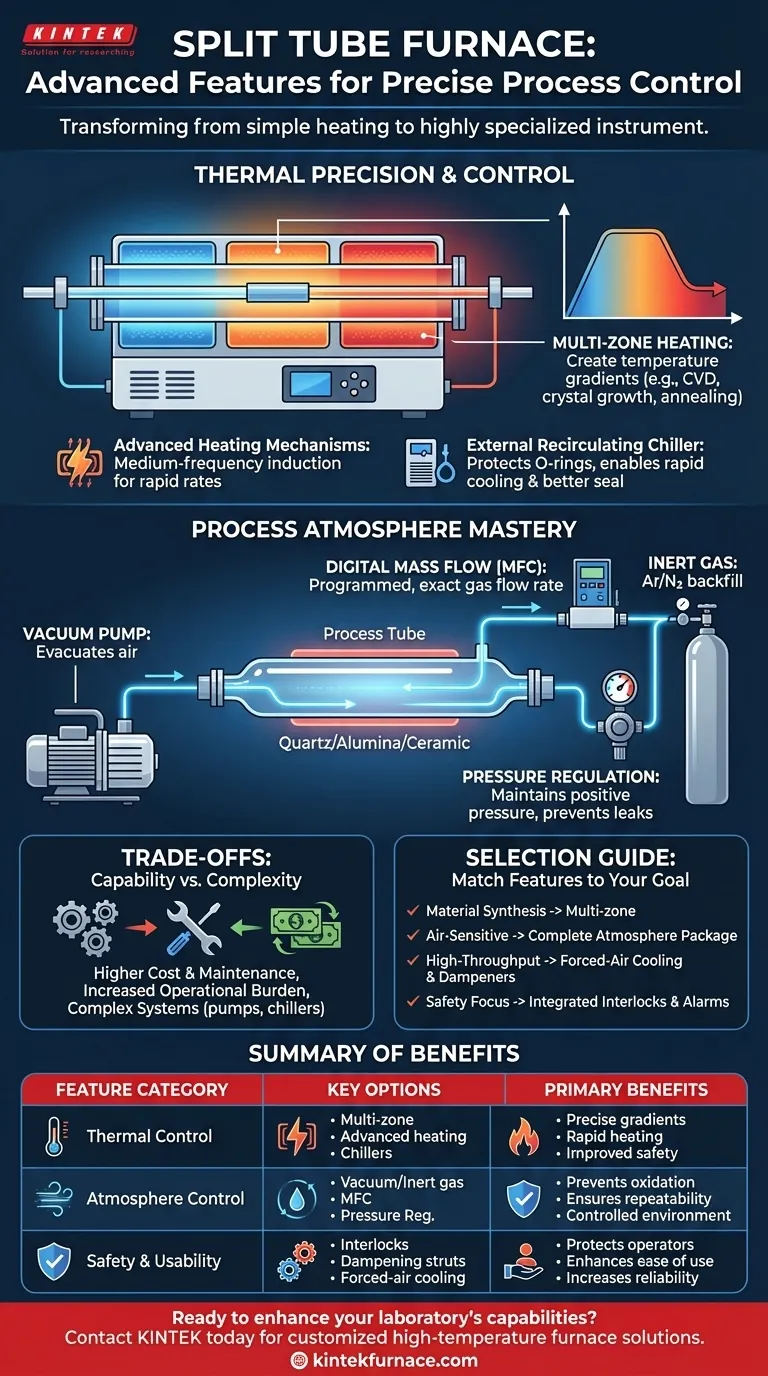

Beyond its core split-hinge design, a split tube furnace can be configured with a sophisticated suite of features for precise process control. These additions often include multi-zone heating for creating temperature gradients, complete atmosphere control systems for operating under vacuum or inert gas, and integrated safety interlocks for protecting both the operator and the experiment. These features transform the furnace from a simple heating chamber into a highly specialized instrument for research and production.

The array of available features serves a single purpose: to give you complete control over the thermal and atmospheric environment inside the process tube. Understanding these options allows you to tailor the furnace precisely to your scientific or industrial goal, avoiding unnecessary complexity while ensuring you have the capabilities you need.

Enhancing Thermal Precision and Control

The primary function of any furnace is heating, but advanced applications demand more than just a single setpoint. Precision is achieved through sophisticated control over how that heat is generated and distributed.

Multi-Zone Heating

A standard furnace has one heated zone, creating a relatively uniform temperature in the center. Furnaces can be optioned with 2, 3, or even 5 independent heating zones along the length of the tube.

This allows you to create controlled temperature gradients, which is critical for processes like chemical vapor deposition (CVD), crystal growth, or specialized annealing where different parts of a sample must be at different temperatures simultaneously.

Advanced Heating Mechanisms

While most furnaces use robust resistive heating coils, some specialized models may employ medium-frequency induction heating. This method offers extremely rapid heating rates but is typically used for specific, compatible materials.

External Cooling Systems

For applications requiring rapid cooling or to protect sensitive components, a recirculating chiller can be integrated. Its primary role is to circulate coolant through the sealing flanges, protecting the O-rings from thermal degradation during high-temperature operation and ensuring a better vacuum seal.

Mastering the Process Atmosphere

Many modern material processes cannot be performed in ambient air. Atmosphere control is arguably the most critical set of additional features for a research furnace.

Vacuum and Inert Gas Capability

The ability to control the atmosphere begins with a sealed system. This involves a high-quality process tube (typically quartz, alumina, or ceramic), specialized sealing flanges, and a vacuum pump.

This setup allows you to first evacuate the air from the tube and then backfill it with a high-purity inert gas like argon or nitrogen, preventing unwanted oxidation or reactions.

Precision Gas Flow Control

To manage the flow of inert or reactive gases, systems can be equipped with different levels of control. A basic setup uses a simple ball-type flow meter for visual estimation.

For high-precision work, a digital mass flow controller (MFC) is essential. An MFC allows you to program and maintain an exact gas flow rate, ensuring process repeatability and precise control over gas-phase reactions.

Pressure Regulation

A complete atmosphere control package also includes a back pressure regulator and isolation valves. This allows you to maintain a positive pressure inside the tube, ensuring no ambient air can leak into your controlled environment.

Understanding the Trade-offs: Capability vs. Complexity

Adding features invariably introduces trade-offs. It is crucial to weigh the benefits of advanced capability against the increased cost and operational complexity.

Cost and Maintenance

Each additional feature, from a mass flow controller to an extra heating zone, increases the initial purchase price. More complex systems with vacuum pumps, chillers, and digital controllers also require more routine maintenance and calibration.

Operational Burden

A simple, single-zone furnace for air-atmosphere heating can be operated with minimal training. A multi-zone furnace with a full vacuum and gas delivery system is a complex instrument that requires a knowledgeable operator to run effectively and safely.

Process Suitability

Over-specifying a furnace is a common mistake. If your process only requires a stable, uniform temperature in air, adding a vacuum system and multiple heating zones adds unnecessary cost and complexity. The key is to match the features directly to the process demands.

Selecting the Right Features for Your Application

Choosing the right configuration depends entirely on your end goal. Use your process requirements as a guide to select only the features you need.

- If your primary focus is material synthesis with precise thermal profiles: Prioritize a multi-zone heating system to create and control temperature gradients.

- If your primary focus is working with air-sensitive materials: A complete atmosphere control package—including a vacuum pump, sealing flanges, and a mass flow controller—is non-negotiable.

- If your primary focus is high-throughput R&D or frequent sample changes: Features like pneumatic dampening struts for assisted opening and a forced-air case cooling system will significantly improve usability and turnaround time.

- If your primary focus is safety and reliability in a multi-user environment: Insist on integrated safety features like over-temperature protection, emergency shut-offs, and clear alarm systems.

By carefully matching the furnace's capabilities to your specific application, you invest in a tool that is both powerful and efficient.

Summary Table:

| Feature Category | Key Options | Primary Benefits |

|---|---|---|

| Thermal Control | Multi-zone heating, Advanced heating mechanisms, External cooling systems | Precise temperature gradients, rapid heating, improved safety |

| Atmosphere Control | Vacuum/inert gas capability, Precision gas flow control, Pressure regulation | Prevents oxidation, ensures repeatability, maintains controlled environment |

| Safety & Usability | Integrated safety interlocks, Pneumatic dampening struts, Forced-air cooling | Protects operators, enhances ease of use, increases reliability |

Ready to enhance your laboratory's capabilities with a customized split tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how we can optimize your thermal processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab