Ultimately, the working conditions inside the chamber are the single most important factor in selecting the right tube furnace. Your specific requirements for maximum temperature, processing atmosphere, and vacuum level directly dictate the furnace's structural design, material composition, and overall cost. Failing to match these conditions correctly will result in either failed processes or an unnecessarily expensive piece of equipment.

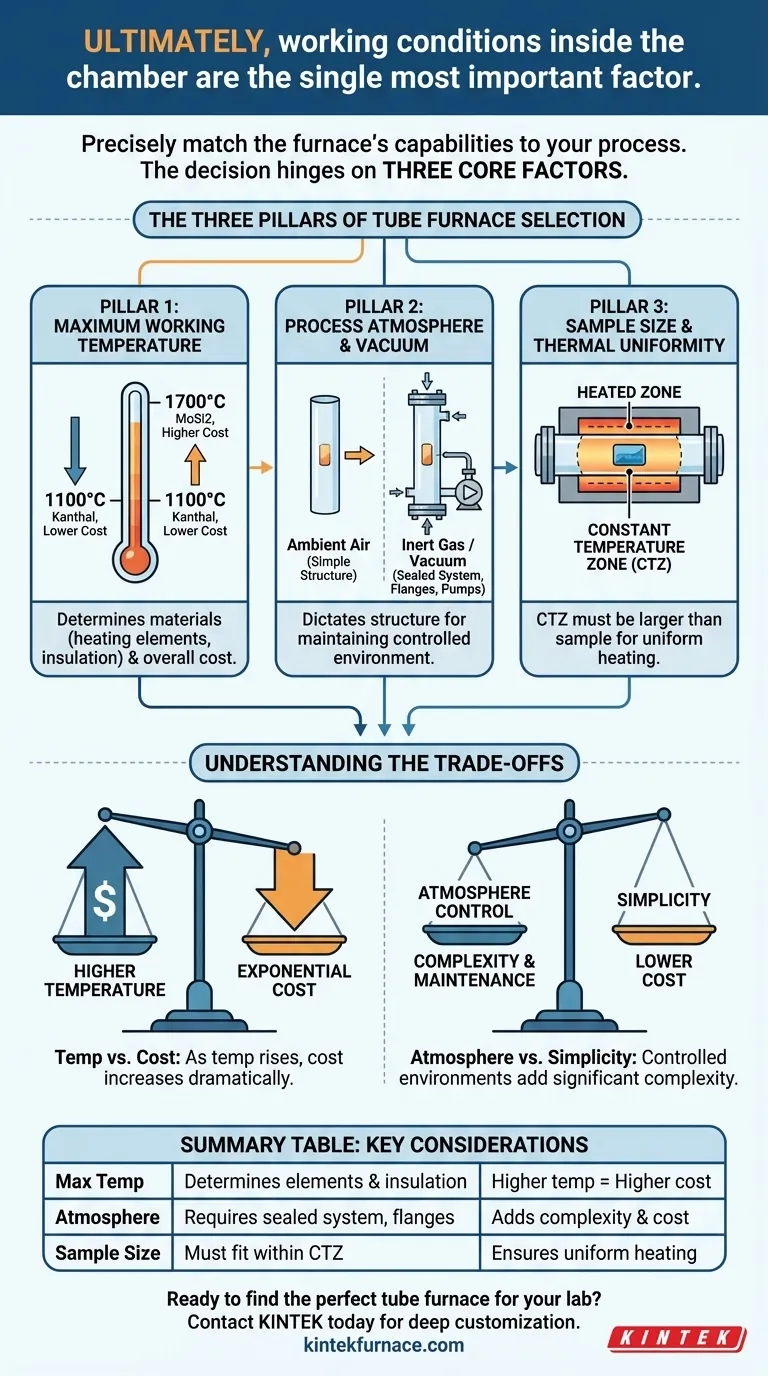

Choosing a tube furnace is not about finding the "best" model, but about precisely matching the furnace's capabilities to your specific application. The decision hinges on three core factors: the temperature you need to reach, the atmosphere you need to maintain, and the size of the sample you need to heat uniformly.

The Three Pillars of Tube Furnace Selection

A tube furnace works by heating a separate work tube that contains your sample. The furnace's design must be able to support the conditions you create inside that tube. This choice rests on three fundamental pillars.

Pillar 1: Maximum Working Temperature

The first and most significant filter in your selection process is temperature. This is because the required temperature range determines the materials used for the furnace's most critical and expensive components.

Furnaces are generally categorized by their temperature capabilities, which correspond to different heating elements and insulation materials. For example, a furnace rated for 1100°C will use different, less expensive components than one designed to reach 1700°C.

You must know the actual processing temperature your material requires. Choosing a furnace with a much higher temperature range than you need will drastically and unnecessarily increase the price.

Pillar 2: Process Atmosphere and Vacuum

The atmosphere surrounding your sample is the next critical consideration. Your process may require an inert gas, a specific reactive gas, or a vacuum.

This requirement directly influences the furnace structure. To maintain a controlled atmosphere or vacuum, the furnace system must include a sealed work tube, typically with specialized vacuum flanges and ports for gas inlet/outlet and pressure gauges.

A simple furnace for heating in ambient air will not have these features. If your work involves protecting samples from oxidation or introducing process gases, a furnace system designed for atmospheric control is non-negotiable.

Pillar 3: Sample Size and Thermal Uniformity

The physical size of your sample dictates the required size of the furnace's heating chamber. However, the critical dimension is not the overall chamber length but the constant temperature zone.

This is the region within the furnace that maintains a stable and uniform temperature. This zone is always smaller than the total heated length of the chamber.

For your process to be successful, the constant temperature zone must be larger than your sample. This ensures the entire sample is heated evenly, preventing inconsistent results. Always verify the specified length of this zone before making a choice.

Understanding the Trade-offs

Every furnace specification involves a trade-off, most often between capability and cost. Understanding these balances is key to making a sound investment.

Temperature vs. Cost

This is the most significant trade-off. As the maximum operating temperature increases, the cost rises exponentially.

A furnace for up to 1200°C might use robust but relatively common Kanthal (FeCrAl) heating elements. A 1700°C furnace, however, requires exotic and fragile Molybdenum Disilicide (MoSi2) elements and higher-grade insulation, dramatically increasing the price.

Atmosphere Control vs. Simplicity

A basic furnace that only heats in air is simple and less expensive. Adding the capability for vacuum and controlled gas flow introduces significant complexity.

This requires vacuum-tight seals, flanges, pumps, and mass flow controllers. While essential for many advanced material processes, these components add cost and maintenance requirements.

Work Tube Material Limitations

The work tube itself is a consumable with limitations. Quartz tubes are common and cost-effective but are generally limited to around 1100-1200°C and can be reactive in certain conditions.

For higher temperatures or more demanding chemical environments, you will need a more expensive alumina or other ceramic tube, which also impacts your operating budget.

Making the Right Choice for Your Goal

To select the correct furnace, start by clearly defining your primary application.

- If your primary focus is high-temperature synthesis (>1200°C): You must select a furnace with appropriate high-temperature heating elements (like SiC or MoSi2) and use a high-purity alumina work tube.

- If your primary focus is controlled atmosphere annealing: Prioritize a furnace system that comes with vacuum flanges, a gas mixing system, and a high-quality seal design.

- If your primary focus is uniform heating of larger samples: Verify the length of the constant temperature zone and ensure it is significantly larger than your sample or workpiece.

- If your primary focus is general-purpose heating on a budget: A simple, lower-temperature (≤1200°C) furnace without complex atmospheric controls is your most cost-effective option.

By clearly defining your operational needs first, you can confidently select a furnace that delivers reliable results without overspending.

Summary Table:

| Factor | Key Consideration | Impact on Selection |

|---|---|---|

| Maximum Temperature | Determines heating elements and insulation | Higher temperatures increase cost; match to actual needs |

| Process Atmosphere | Requires sealed tubes, vacuum flanges, gas controls | Adds complexity and cost; essential for inert/reactive gases |

| Sample Size | Must fit within constant temperature zone | Ensures uniform heating; verify zone length for consistency |

Ready to find the perfect tube furnace for your lab? Contact KINTEK today via our contact form to discuss your specific needs. Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, helping you achieve reliable results and cost efficiency. Let's optimize your high-temperature processes together!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing