In advanced materials processing, three-zone tube furnaces are indispensable for applications requiring exceptionally precise thermal control, such as chemical vapor deposition (CVD), the annealing of semiconductor wafers, and the controlled growth of single crystals. Their unique ability to create either extended uniform heat zones or precise temperature gradients makes them fundamental tools in fabricating next-generation materials for electronics, energy, and biomedical fields.

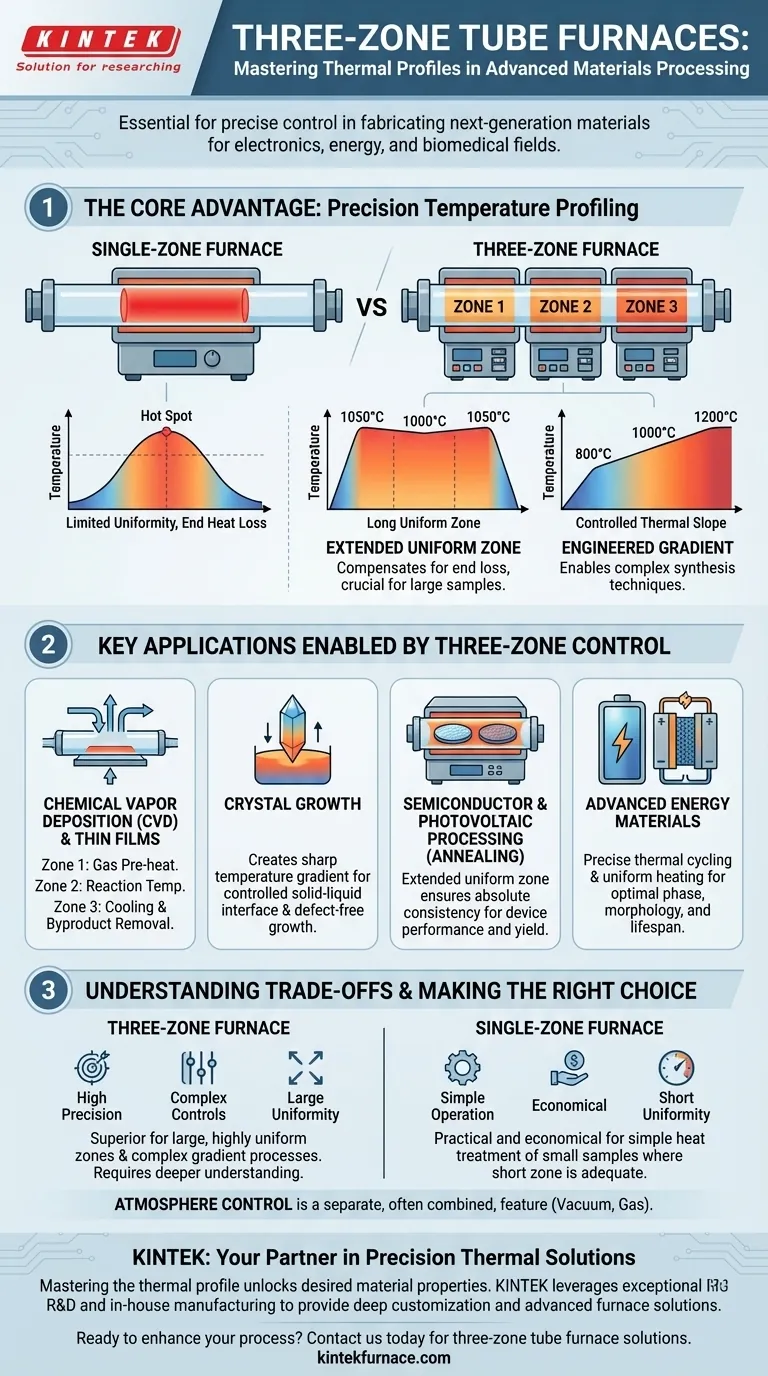

The critical value of a three-zone furnace is not just heat, but the precise control of the thermal profile across a sample. While a single-zone furnace creates a hot spot, a three-zone furnace allows you to engineer a complete thermal landscape, which is essential for processes where temperature variations of even a few degrees can dictate success or failure.

The Core Advantage: Precision Temperature Profiling

The defining feature of a three-zone furnace is its three independently controlled heating elements. This design provides a level of thermal management that single-zone furnaces cannot match.

Beyond Simple Uniformity

A standard single-zone furnace naturally loses heat at its ends, resulting in a relatively short, truly uniform temperature zone in the very center. This limits the size of the sample or the number of samples that can be processed consistently.

Creating an Extended Uniform Zone

By setting the two end zones to a slightly higher temperature than the center zone, a three-zone furnace actively compensates for this natural heat loss. The result is a significantly longer and more stable uniform temperature zone, crucial for processes like annealing large semiconductor wafers where every part of the material must experience the exact same conditions.

Engineering a Temperature Gradient

The most powerful capability is creating a controlled temperature gradient. By setting each of the three zones to a different temperature, you can establish a precise thermal slope along the length of the processing tube. This is not a bug; it is a critical feature for many advanced synthesis techniques.

Key Applications Enabled by Three-Zone Control

The ability to manipulate the thermal profile directly enables processes that are impossible or unreliable in simpler furnaces.

Chemical Vapor Deposition (CVD) and Thin Films

CVD involves flowing precursor gases over a heated substrate to deposit a thin, solid film. A three-zone furnace allows for an ideal process flow: the first zone pre-heats the gas, the center zone provides the precise reaction temperature at the substrate, and the third zone can be set to control the cooling and removal of byproducts.

Crystal Growth

Growing large, high-purity single crystals often requires slowly pulling a seed crystal from a melt. A three-zone furnace can establish the sharp temperature gradient needed to control the solid-liquid interface, ensuring the crystal grows with the desired structure and minimal defects.

Semiconductor and Photovoltaic Processing

Annealing is a heat treatment process that alters a material's microstructure to relieve stress and improve properties. For semiconductor wafers or photovoltaic cells, ensuring the entire surface is annealed with absolute uniformity is critical for device performance and yield. A three-zone furnace's extended uniform zone is purpose-built for this task.

Advanced Energy Materials

The synthesis of components for solid oxide fuel cells and next-generation batteries often requires precise thermal cycling and uniform heating to achieve the correct crystalline phase and morphology. Inconsistent heating can lead to poor performance and reduced lifespan of the final device.

Understanding the Trade-offs

While powerful, a three-zone furnace is not always the necessary choice. Understanding its purpose helps in making an informed decision.

Complexity vs. Simplicity

A three-zone furnace has more complex controls and requires a deeper understanding of thermal dynamics to program effectively. For simple heat treatment of a small sample where a short uniform zone is sufficient, a more economical single-zone furnace is often the more practical tool.

Atmosphere is a Separate Variable

The term "three-zone" refers only to the temperature control. The furnace's ability to operate under vacuum or a specific gas atmosphere is a separate, though often combined, feature. Many applications, like preventing oxidation, require both multi-zone control and atmosphere control.

Batch vs. Continuous Processing

Tube furnaces are inherently batch processors. For high-volume, continuous manufacturing of powders or granular materials, a rotary tube furnace may offer better throughput and efficiency, as it tumbles the material through the hot zone.

Making the Right Choice for Your Process

Your specific goal determines whether the advanced capabilities of a three-zone furnace are required.

- If your primary focus is a large, highly uniform temperature zone for batch annealing or consistent treatment of multiple samples, a three-zone furnace is the superior choice for maximizing sample throughput and consistency.

- If your primary focus is a process requiring a temperature gradient, such as Chemical Vapor Deposition (CVD), vapor transport, or specific crystal growth methods, a three-zone furnace is essential.

- If your primary focus is simple heat treatment of small, single samples where a short uniform hot zone is adequate, a single-zone furnace provides the necessary function more economically.

Ultimately, mastering the thermal profile is the key to unlocking the desired properties in your material, and a three-zone furnace provides the highest degree of control to achieve that.

Summary Table:

| Application | Key Benefit |

|---|---|

| Chemical Vapor Deposition (CVD) | Precise temperature control for gas pre-heat, reaction, and cooling |

| Annealing of Semiconductor Wafers | Extended uniform heat zone for consistent material properties |

| Crystal Growth | Controlled temperature gradients for defect-free single crystals |

| Advanced Energy Materials | Uniform heating for optimal phase and morphology in batteries and fuel cells |

Ready to enhance your advanced materials processing with precise thermal control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our three-zone tube furnaces can optimize your processes and drive innovation in your lab!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing