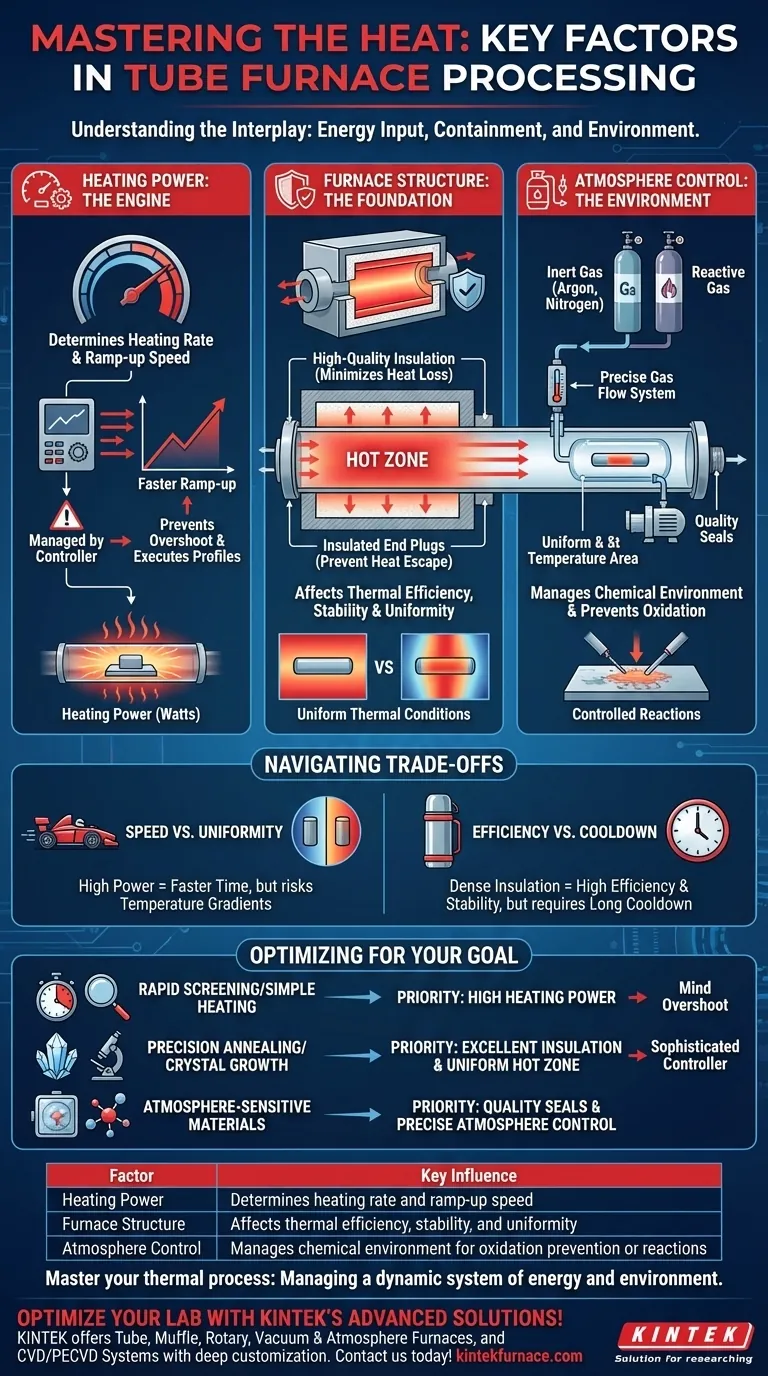

In any thermal processing application, the performance of a tube furnace is governed by three primary factors. These are the heating power, which dictates the rate of temperature change; the furnace's physical structure and insulation, which determine its thermal efficiency and stability; and the atmosphere control system, which manages the chemical environment around the sample.

Understanding the interplay between these three elements—energy input (power), energy containment (structure), and a controlled environment (atmosphere)—is the key to moving beyond simply heating a sample to achieving precise, repeatable, and successful material processing.

Deconstructing the Heating Process

To master a tube furnace, you must understand how each core component contributes to the final result. They are not independent variables but parts of an interconnected system.

Heating Power: The Engine of Temperature Change

Heating power directly determines the furnace's heating rate, or how quickly it can reach the target temperature. A higher power output allows for a faster ramp-up time.

However, raw power must be managed by a sophisticated controller. This controller modulates the power to prevent temperature overshoot and to execute precise heating profiles, including controlled ramps and extended "soaks" at a stable temperature.

Furnace Structure: The Foundation of Stability

The physical design and insulation of the furnace are critical for heat retention and temperature uniformity. High-quality insulation minimizes heat loss to the surrounding environment, reducing energy consumption.

This efficiency directly contributes to creating a stable and uniform hot zone. This is the central area of the furnace chamber where the temperature is most consistent, which is essential for ensuring your entire sample experiences the same thermal conditions.

Features like insulated end plugs are not trivial; they play a significant role in preventing heat from escaping the ends of the tube, further improving uniformity and stability.

Atmosphere Control: The Chemical Environment

Many advanced materials require processing in a specific gaseous environment to prevent oxidation or to induce a chemical reaction. This is the role of the atmosphere control system.

By flowing inert gases like argon or nitrogen, you can create an oxygen-free environment. Alternatively, reactive gases can be introduced to perform specific surface treatments. The quality of the furnace's seals and the precision of the gas flow system are paramount for this function.

Understanding the Inherent Trade-offs

Choosing or operating a tube furnace involves balancing competing priorities. Being aware of these trade-offs is crucial for setting realistic expectations and designing effective experiments.

Speed vs. Uniformity

A very high heating rate, achieved with high power, can save time. However, it often comes at the cost of temperature uniformity, creating gradients where the outside of a sample is hotter than its core.

For processes that demand high precision, such as crystal growth or delicate annealing, a slower, more controlled heating ramp is almost always superior for achieving uniform thermal treatment.

Efficiency vs. Cooldown Time

Furnaces with thick, dense insulation are highly energy-efficient and offer excellent temperature stability. The downside is their high thermal mass, which means they can take a very long time to cool down.

This slow cooling can be a benefit for some annealing processes, but it can also be a significant bottleneck in a high-throughput lab environment where rapid cycling is needed.

Optimizing Your Furnace for Your Goal

Your specific application dictates which factor you should prioritize. Use these guidelines to inform your approach.

- If your primary focus is rapid screening or simple heating: A furnace with high heating power will serve you well, but be mindful of potential temperature overshoot.

- If your primary focus is precision annealing or crystal growth: Prioritize a furnace with excellent insulation, a well-defined uniform hot zone, and a sophisticated temperature controller.

- If your primary focus is processing atmosphere-sensitive materials: The quality of the vacuum seals and the precision of the atmosphere control system are your most critical factors.

Mastering your thermal process begins with understanding that you are not just setting a temperature, but managing a dynamic system of energy and environment.

Summary Table:

| Factor | Key Influence |

|---|---|

| Heating Power | Determines heating rate and ramp-up speed |

| Furnace Structure | Affects thermal efficiency, stability, and uniformity |

| Atmosphere Control | Manages chemical environment for oxidation prevention or reactions |

Optimize your lab's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored products like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and repeatability. Contact us today to discuss how we can support your material processing goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision