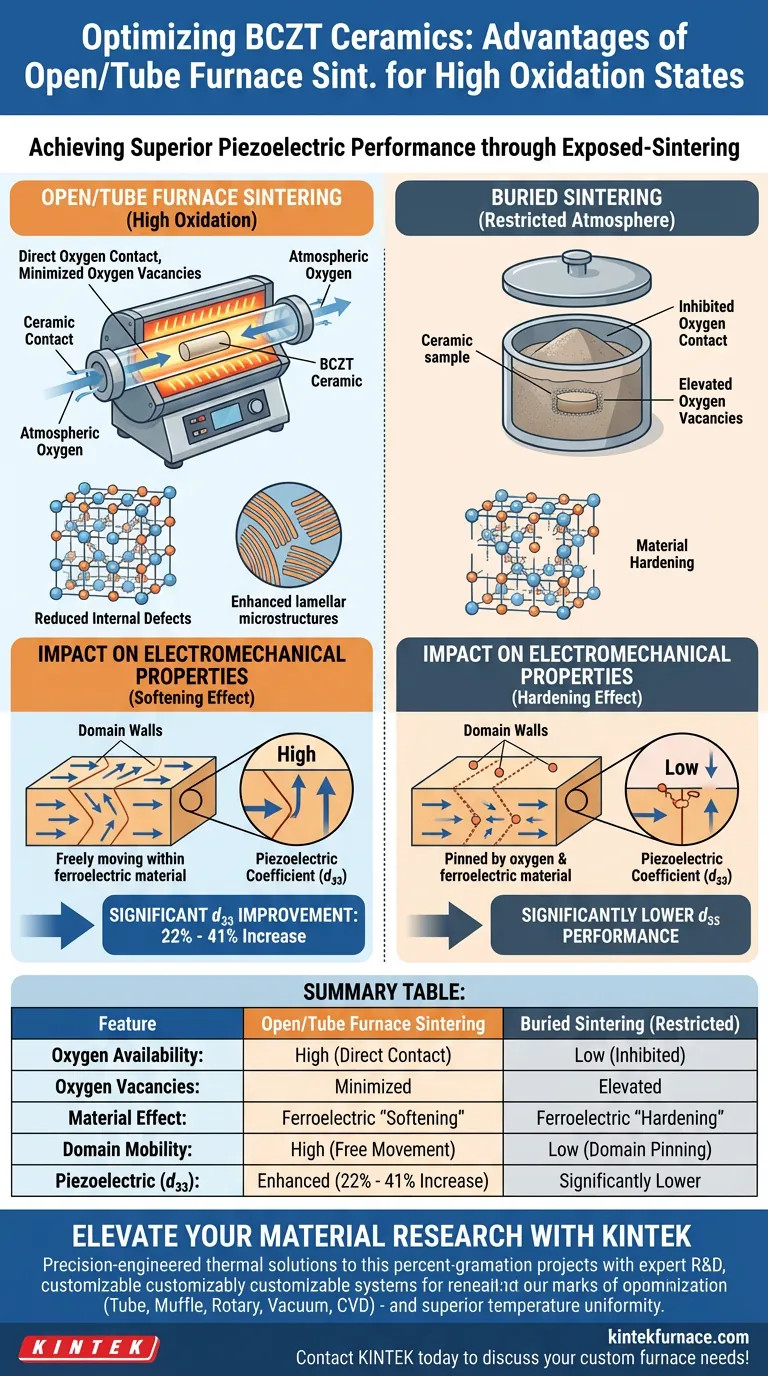

Utilizing a laboratory tube furnace or an open sintering furnace offers the distinct advantage of maintaining full, direct contact between the (Ba0.85Ca0.15)(Zr0.1Ti0.9)O3 (BCZT) ceramic and atmospheric oxygen. This "exposed-sintering" environment is critical for minimizing oxygen vacancies, which directly correlates to a significant enhancement in piezoelectric performance.

Core Takeaway Achieving a high oxidation state in BCZT ceramics prevents the formation of oxygen vacancies that "pin" domain walls. This results in a ferroelectric "softening" effect, increasing domain mobility and boosting the piezoelectric coefficient ($d_{33}$) by 22% to 41% compared to samples sintered in restricted environments.

The Mechanism of Oxidation and Performance

Maximizing Oxygen Contact

The primary benefit of an open or tube furnace is the unrestricted availability of oxygen. Unlike buried-sintering methods, where samples are embedded in powder, open sintering allows the ceramic surface to interact freely with the atmosphere.

Reduction of Internal Defects

This direct exposure facilitates a thorough oxidation process. By ensuring sufficient oxygen is available during the high-temperature phase (typically 1300–1500°C), the concentration of internal oxygen vacancies is significantly reduced.

Enhancement of Lamellar Structures

This oxidation is particularly beneficial for ceramics exhibiting lamellar structures. The open-air environment ensures that these complex microstructures do not suffer from oxygen deficiencies that would otherwise degrade their electrical properties.

Impact on Electromechanical Properties

The "Softening" Effect

Reducing oxygen vacancies leads to a phenomenon known as material "softening." In ferroelectrics, oxygen vacancies often act as pinning sites that restrict the movement of domain walls.

Increased Domain Mobility

When these pinning sites are removed through high oxidation, the domain walls within the BCZT structure can move more freely. This mobility is the fundamental driver of high piezoelectric response in these materials.

Significant $d_{33}$ Improvement

The practical result of this enhanced mobility is a measurable increase in the piezoelectric coefficient ($d_{33}$). Open-sintered BCZT ceramics can exhibit $d_{33}$ values 22% to 41% higher than their dense, oxygen-deficient counterparts.

Understanding the Trade-offs: Open vs. Buried

The Risks of Buried Sintering

It is important to understand what you avoid by using an open furnace. The alternative "buried-sintering" method limits air contact, inhibiting the oxidation process.

Material Hardening

When oxidation is inhibited, oxygen vacancy concentrations rise. This leads to ferroelectric "hardening," characterized by reduced polarization intensity and a significant drop in piezoelectric performance.

Temperature Uniformity Considerations

While open furnaces excel at oxidation, the sintering process also requires precise kinetic conditions for grain growth and densification. Ensure your furnace maintains superior temperature uniformity, as this dictates the final grain size distribution and density.

Making the Right Choice for Your Goal

-

If your primary focus is maximizing piezoelectric sensitivity ($d_{33}$): Choose an open or tube furnace to ensure full oxidation, reduce vacancy pinning, and achieve the "softest" material response possible.

-

If your primary focus is densification and grain control: Ensure your open furnace setup offers excellent temperature uniformity (1300–1500°C range), as this controls pore elimination and grain growth regardless of the atmosphere.

By prioritizing an oxygen-rich sintering environment, you effectively unlock the full potential of domain mobility within the BCZT lattice.

Summary Table:

| Feature | Open/Tube Furnace Sintering | Buried Sintering (Restricted) |

|---|---|---|

| Oxygen Availability | High (Direct Contact) | Low (Inhibited) |

| Oxygen Vacancies | Minimized | Elevated |

| Material Effect | Ferroelectric "Softening" | Ferroelectric "Hardening" |

| Domain Mobility | High (Free Movement) | Low (Domain Pinning) |

| Piezoelectric ($d_{33}$) | Enhanced (22% - 41% Increase) | Significantly Lower |

Elevate Your Material Research with KINTEK

Maximize the piezoelectric performance of your BCZT ceramics with precision-engineered thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all customizable to meet your specific oxidation and sintering requirements. Our furnaces provide the superior temperature uniformity and atmospheric control necessary to eliminate oxygen vacancies and unlock superior domain mobility.

Ready to optimize your high-temperature processes? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Zihe Li, Chris Bowen. Porous Structure Enhances the Longitudinal Piezoelectric Coefficient and Electromechanical Coupling Coefficient of Lead‐Free (Ba<sub>0.85</sub>Ca<sub>0.15</sub>)(Zr<sub>0.1</sub>Ti<sub>0.9</sub>)O<sub>3</sub>. DOI: 10.1002/advs.202406255

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What environmental conditions does a vacuum tube furnace provide for FTO(p)/ZnS(p) films? High-Purity Post-Treatment

- How does the industrial tube furnace contribute to Fe-N-C catalyst synthesis? Master High-Temperature Carbonization

- How is temperature controlled in a Tube Furnace? Master Precise Thermal Processes for Your Lab

- What are the benefits of induction heating tube furnaces? Unlock Speed, Precision, and Efficiency

- How do researchers utilize the heating elements in tubular furnaces? Unlock Precise Thermal Control for Advanced Materials Research

- Why is a tantalum tube encapsulated in a vacuum quartz tube? Prevent Oxidation & Embrittlement in High-Temp Calcination

- How can the uniform length of a tube furnace be improved? Boost Temperature Uniformity with Proven Methods

- What critical reaction conditions does a tube furnace provide during the synthesis of SFC5 materials?