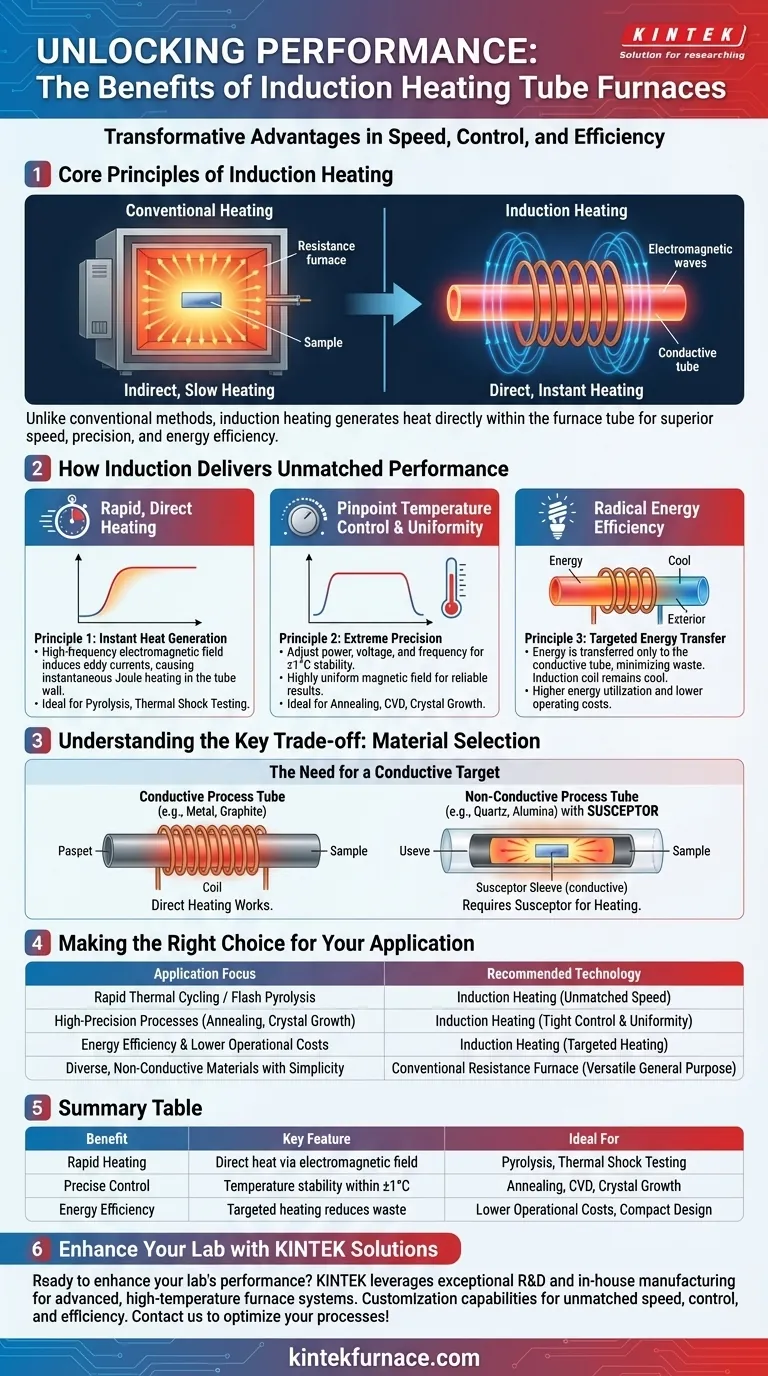

At its core, an induction heating tube furnace offers three transformative benefits over conventional methods: exceptional speed, pinpoint control, and superior energy efficiency. These advantages stem from its unique ability to generate heat directly within the furnace tube itself, rather than relying on slow, indirect heating elements.

While conventional furnaces heat a large chamber to slowly radiate warmth onto a sample, induction furnaces use an electromagnetic field to instantly generate heat inside the conductive furnace tube. This fundamental difference is the source of its primary advantages in speed, precision, and efficiency.

How Induction Delivers Unmatched Performance

The benefits of induction heating are not just incremental improvements; they are the result of a fundamentally different physical process. Understanding this process clarifies why it excels in demanding applications.

Principle 1: Rapid, Direct Heating

An induction coil generates a high-frequency electromagnetic field. When a conductive material, such as a metal or graphite furnace tube, is placed inside this field, the field induces powerful eddy currents within the tube wall.

The resistance of the tube material to these currents generates instantaneous and intense heat—a principle known as Joule heating. This allows the furnace to reach target temperatures in a fraction of the time required by resistance furnaces, which must first heat up bulky ceramic elements and then slowly radiate that heat inwards.

This rapid heating is critical for processes like pyrolysis or thermal shock testing, where the rate of temperature change is a key process variable.

Principle 2: Pinpoint Temperature Control and Uniformity

Because the heat is generated by an electromagnetic field, the temperature can be controlled with extreme precision by adjusting the power supply's current, voltage, and frequency.

This direct and instantaneous control allows for maintaining temperature stability often within ±1°C, ensuring highly repeatable and reliable results.

Furthermore, the induction coil can be engineered to create a highly uniform magnetic field along the length of the process zone. This ensures excellent temperature uniformity, which is vital for applications like chemical vapor deposition (CVD) and the annealing of metals, where even small temperature variations can compromise results.

Principle 3: Radical Energy Efficiency

In a conventional furnace, a significant amount of energy is wasted heating the furnace walls, insulation, and the surrounding air. Induction heating is far more targeted.

The energy is transferred directly to the conductive furnace tube, with very little heat escaping to the environment. Only the workpiece gets hot, while the induction coil itself remains cool to the touch.

This targeted approach results in significantly higher energy utilization and lower operating costs, as less electricity is wasted as ambient heat. The compact design of induction systems also saves valuable lab or factory floor space.

Understanding the Key Trade-off: Material Selection

While powerful, the mechanism of induction heating introduces a critical consideration that defines its use cases.

The Need for a Conductive Target

Induction heating only works on materials that conduct electricity. If your process requires a non-conductive tube, like quartz or alumina, for chemical inertness, it will not heat up on its own in the induction coil.

The solution is to use a susceptor—a sleeve or tube made of a conductive material (like graphite or silicon carbide) that is placed inside the non-conductive process tube.

The induction field heats the susceptor, which then radiates heat to the sample inside. This maintains the benefits of rapid heating and control while allowing for the use of non-conductive process tubes.

Conventional vs. Induction Heating

A resistance-heated furnace is simpler and will heat any material placed inside it, making it a versatile general-purpose tool.

An induction furnace offers superior performance in speed, control, and efficiency, but it requires either a conductive process tube or the use of a susceptor.

Making the Right Choice for Your Application

The decision to use an induction tube furnace should be driven by the specific demands of your process.

- If your primary focus is rapid thermal cycling or flash pyrolysis: The unmatched heating and cooling speed of induction is the clear advantage.

- If your primary focus is high-precision processes like annealing or crystal growth: The tight temperature control and uniformity of an induction system will deliver more reliable and repeatable results.

- If your primary focus is energy efficiency and lower operational costs: The targeted heating of induction significantly reduces wasted energy compared to a conventional furnace that is on for long periods.

- If your primary focus is processing diverse, non-conductive materials with maximum simplicity: A conventional resistance-heated tube furnace may be a more straightforward and flexible choice.

Choosing the right technology hinges on understanding your most critical process requirements.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Rapid Heating | Direct heat generation via electromagnetic field | Pyrolysis, thermal shock testing |

| Precise Control | Temperature stability within ±1°C | Annealing, CVD, crystal growth |

| Energy Efficiency | Targeted heating reduces waste | Lower operational costs, compact design |

Ready to enhance your lab's performance with tailored induction heating solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including Tube Furnaces and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering unmatched speed, control, and efficiency. Contact us today to discuss how we can optimize your processes and drive better results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing