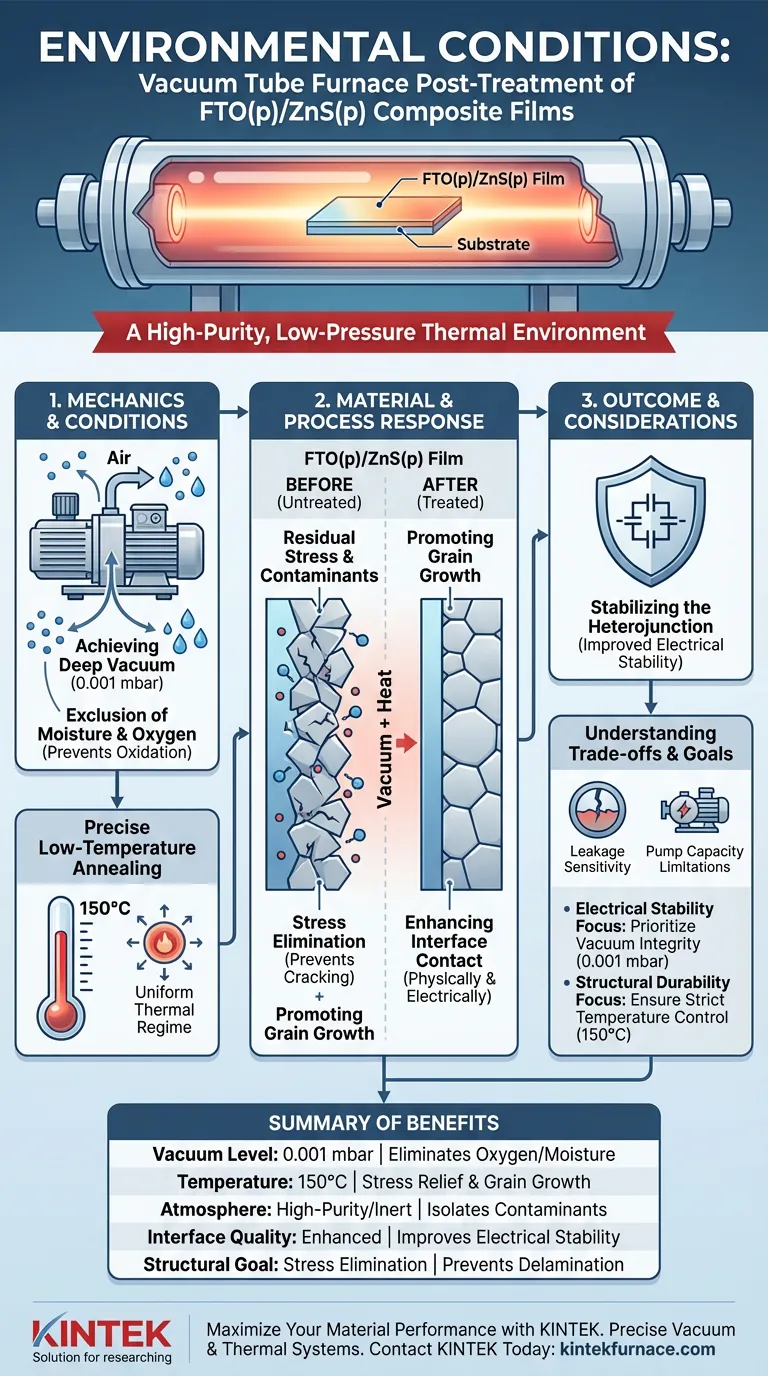

A vacuum tube furnace establishes a high-purity, low-pressure thermal environment designed to strictly isolate composite films from atmospheric contaminants. For FTO(p)/ZnS(p) composite films specifically, this equipment utilizes a mechanical pump to achieve a vacuum level of 0.001 mbar while maintaining a stable annealing temperature of 150°C. This setup is critical for excluding oxidizing agents like oxygen and moisture that would otherwise degrade the material properties.

By maintaining a consistent vacuum of 0.001 mbar during the 150°C annealing process, the furnace serves as a protective barrier against oxidation. This controlled environment is the defining factor in relieving internal film stresses and securing the structural integrity of the heterojunction.

The Mechanics of the Controlled Environment

To understand why this specific environment is necessary for FTO(p)/ZnS(p) films, we must look at the interplay between pressure, temperature, and material chemistry.

Achieving Deep Vacuum

The primary function of the furnace in this context is pressure reduction. By using a mechanical pump to reach 0.001 mbar, the system creates a near-void environment.

This drastic reduction in pressure removes the vast majority of air molecules from the chamber. It ensures that the film is treated in isolation, rather than reacting with the surrounding atmosphere.

Exclusion of Moisture and Oxygen

The vacuum environment specifically targets the removal of oxygen and moisture. These are the two most detrimental elements to the stability of FTO and ZnS composites during thermal treatment.

By stripping these elements away, the furnace prevents unwanted chemical reactions, such as oxidation, which could compromise the purity of the film surfaces.

Thermal Treatment and Material Response

The environment is not just about what is removed; it is about how the heat is applied within that void.

Precise Low-Temperature Annealing

The process involves heating the films to 150°C.

While many ceramics require extremely high temperatures, this specific composite requires a moderate thermal regime. The tube furnace maintains this temperature uniformly, ensuring the entire film surface is treated equally.

Stress Elimination

One of the most critical roles of this environment is the elimination of internal stresses.

Films often harbor residual stress from the deposition process. Annealing in this vacuum eliminates these stresses, preventing future cracking or delamination.

Promoting Grain Growth

The thermal energy provided at 150°C encourages the grains within the film to grow and coalesce.

Larger, more uniform grains generally lead to better material properties. The vacuum ensures this growth happens without the interference of grain-boundary oxidation.

Interface Optimization

For composite films like FTO(p)/ZnS(p), the performance is dictated by the quality of the junction between the materials.

Enhancing Interface Contact

The combination of vacuum pressure and thermal energy optimizes the contact at the interface between the FTO and ZnS layers.

Poor contact leads to high electrical resistance. This process ensures the layers adhere physically and electrically.

Stabilizing the Heterojunction

Ultimately, the goal of this environment is to improve the electrical stability of the heterojunction.

By removing contaminants and relieving stress, the vacuum tube furnace ensures the junction performs reliably over time.

Understanding the Trade-offs

While a vacuum tube furnace is highly effective, it is essential to recognize the operational constraints and potential pitfalls of this method.

Leakage Sensitivity

The system relies entirely on the integrity of the vacuum seals. Even a microscopic leak can introduce enough oxygen to ruin the annealing process at 0.001 mbar.

Regular maintenance of O-rings and flanges is non-negotiable to maintain the protective environment.

Pump Capacity Limitations

Achieving 0.001 mbar requires a robust mechanical pump.

If the pump is underpowered or poorly maintained, it may stabilize at a higher pressure (e.g., 0.1 mbar). This insufficient vacuum can lead to partial oxidation, resulting in a film that is structurally sound but electrically compromised.

Making the Right Choice for Your Goal

When configuring your post-treatment process for FTO(p)/ZnS(p) films, align your furnace settings with your specific material objectives.

- If your primary focus is Electrical Stability: Prioritize the integrity of the vacuum (0.001 mbar) to ensure the interface between FTO and ZnS is free of oxides.

- If your primary focus is Structural Durability: Ensure the temperature is held strictly at 150°C to maximize stress relief without inducing thermal degradation.

The vacuum tube furnace is not just a heater; it is a precision tool that creates the specific exclusion zone required to turn a raw composite film into a stable, high-performance heterojunction.

Summary Table:

| Feature | Specification/Impact | Benefit for FTO(p)/ZnS(p) |

|---|---|---|

| Vacuum Level | 0.001 mbar | Eliminates oxygen and moisture to prevent oxidation |

| Temperature | 150°C (Annealing) | Facilitates stress relief and promotes grain growth |

| Atmosphere | High-Purity/Inert | Isolates films from environmental contaminants |

| Interface Quality | Enhanced Contact | Improves electrical stability of the heterojunction |

| Structural Goal | Stress Elimination | Prevents cracking and delamination of composite layers |

Maximize Your Material Performance with KINTEK

Precision matters when treating sensitive FTO(p)/ZnS(p) composite films. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet your most rigorous laboratory requirements.

Our furnaces provide the stable, high-vacuum environments and uniform thermal control necessary to ensure your heterojunctions are free from oxidation and internal stress. Whether you need a standard setup or a fully customizable system for unique research needs, our team is ready to support your success.

Ready to elevate your lab’s capabilities? Contact KINTEK Today to Find Your Solution

Visual Guide

References

- Ahmad Aljader. Fabrication of FTO(P)/ZNS(P)/SI(N) Heterojunction and Study of Its Structural, Optical and Electrical Properties. DOI: 10.52783/pst.953

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the purpose of using a high-temperature tube sintering furnace for selenization? Optimize PC-CNT Porosity

- What is the function of a multi-zone tube furnace in CVD synthesis? Master 2D In2Se3 Nanosheet Precision

- What factors should be considered when selecting between a tube furnace and a box furnace? Optimize Your Lab's Thermal Processing

- Why is an inert atmosphere tube furnace required for P3-type layered oxide synthesis? Ensure Pure Crystal Structures

- How does the working temperature range affect the choice of a tube furnace? Match Your Lab's Thermal Needs for Precision and Cost-Efficiency

- What process conditions does a tube furnace provide for Au-Ni-TiO2 nanowires? Master 1000°C VLS Synthesis

- What is the function of an industrial tube furnace in NdFeB recycling? Unlock Efficient Rare Earth Recovery

- What role does a Tube Furnace play in the CVD growth of carbon nanotubes? Achieve High-Purity CNT Synthesis