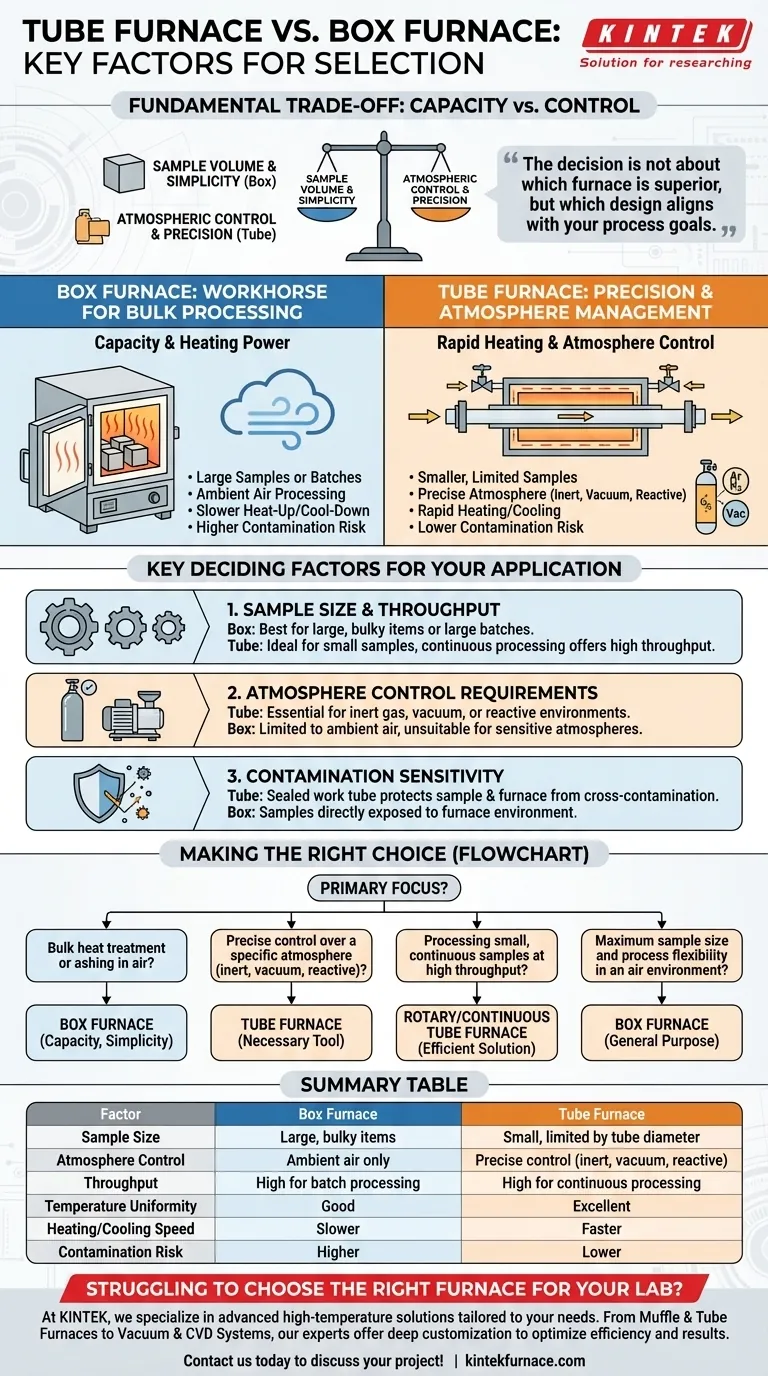

At its core, the choice between a tube furnace and a box furnace comes down to a fundamental trade-off between sample volume and atmospheric control. A box furnace is designed for processing larger samples or batches in ambient air, while a tube furnace excels at providing precise thermal treatment to smaller samples within a tightly controlled gaseous environment.

The decision is not about which furnace is superior, but which design aligns with your process goals. Box furnaces offer capacity and simplicity for bulk processing, whereas tube furnaces provide precision and atmospheric control for specialized applications.

The Fundamental Design Difference: Capacity vs. Control

The physical structure of each furnace type dictates its ideal use case. Understanding this core difference is the first step in making the correct choice.

Box Furnaces: The Workhorse for Bulk Processing

A box furnace, also known as a muffle furnace, is essentially an insulated chamber with a large door at the front. Its design prioritizes capacity and heating power.

These furnaces are built to handle large individual items or large batches of smaller parts. They are the standard for general-purpose applications like annealing, hardening, ashing, or other heat treatments where the ambient air atmosphere is acceptable.

Tube Furnaces: Precision and Atmosphere Management

A tube furnace features a cylindrical heating chamber through which a separate work tube, typically made of ceramic, quartz, or metal, is placed. The samples are processed inside this tube.

This design offers two distinct advantages. First, the smaller volume allows for rapid heating and cooling rates and excellent temperature uniformity. Second, the work tube can be sealed, enabling precise control of the atmosphere around the sample, from inert gases like argon to reactive gases or a vacuum.

Key Deciding Factors for Your Application

Beyond the basic design, several critical factors will guide your decision. Your specific process requirements must be the primary driver.

Factor 1: Sample Size and Throughput

The most immediate consideration is the size and quantity of what you need to process. A box furnace is the obvious choice for a single, large component that simply will not fit in a tube.

For smaller samples, the choice depends on throughput. A box furnace can handle a large batch at once. However, some tube furnaces can be configured for continuous processing, where material flows through the tube, often offering faster overall throughput than the repeated heating and cooling cycles of a batch-style box furnace.

Factor 2: Atmosphere Control Requirements

This is often the most important deciding factor. If your process requires anything other than an ambient air environment, a tube furnace is almost always the correct answer.

The sealed work tube is essential for preventing oxidation by using an inert gas (e.g., Nitrogen, Argon), performing processes in a vacuum, or introducing reactive gases. Achieving this level of control in a standard box furnace is impractical and often impossible.

Factor 3: Contamination Sensitivity

Because samples are placed directly inside a sealed work tube, a tube furnace provides superior protection for both the sample and the furnace.

The work tube prevents sample outgassing from contaminating the furnace's insulation and heating elements. Conversely, it also protects highly sensitive samples from any particles shedding from the furnace interior.

Understanding the Trade-offs and Limitations

No equipment choice is without compromise. Being aware of the inherent limitations of each furnace type is critical for avoiding costly mistakes and operational frustration.

The Constraints of Box Furnaces

The primary limitation of a box furnace is its lack of atmospheric control. Samples are directly exposed to air, which can be detrimental for many materials at high temperatures.

They also have significant thermal mass, leading to slower heat-up and cool-down cycles compared to the nimble response of a smaller tube furnace.

The Constraints of Tube Furnaces

The most significant limitation of a tube furnace is its restricted sample size and geometry. You are fundamentally limited by the diameter of the work tube.

Furthermore, work tubes are consumables. They can be fragile, especially ceramic and quartz, and represent an ongoing operational cost. A catastrophic tube failure can also damage the furnace itself.

The Impact of Orientation: Horizontal vs. Vertical

Within tube furnaces, orientation matters. Horizontal furnaces are common and easy to load, while vertical furnaces are ideal for processing powders or molten samples to avoid contact with the tube wall and improve uniformity.

Making the Right Choice for Your Process

To select the right furnace, you must align the equipment's core strengths with your primary process objective.

- If your primary focus is bulk heat treatment or ashing in air: A box furnace offers the best combination of capacity, simplicity, and cost-effectiveness.

- If your primary focus is precise control over a specific atmosphere (inert, vacuum, reactive): A tube furnace is the necessary tool for the job.

- If your primary focus is processing small, continuous samples at high throughput: A rotary or continuous-feed tube furnace is the most efficient solution.

- If your primary focus is maximum sample size and process flexibility in an air environment: A box furnace provides the versatility needed for general-purpose lab work.

Ultimately, choosing the right furnace is an exercise in matching the tool's inherent design to your specific scientific or production goal.

Summary Table:

| Factor | Box Furnace | Tube Furnace |

|---|---|---|

| Sample Size | Large, bulky items | Small, limited by tube diameter |

| Atmosphere Control | Ambient air only | Precise control (inert, vacuum, reactive) |

| Throughput | High for batch processing | High for continuous processing |

| Temperature Uniformity | Good | Excellent |

| Heating/Cooling Speed | Slower | Faster |

| Contamination Risk | Higher | Lower |

Struggling to choose the right furnace for your lab? At KINTEK, we specialize in advanced high-temperature solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—with strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need bulk processing or precise atmospheric control, our experts can help you optimize efficiency and results. Contact us today to discuss your project and discover how KINTEK can elevate your thermal processing!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput