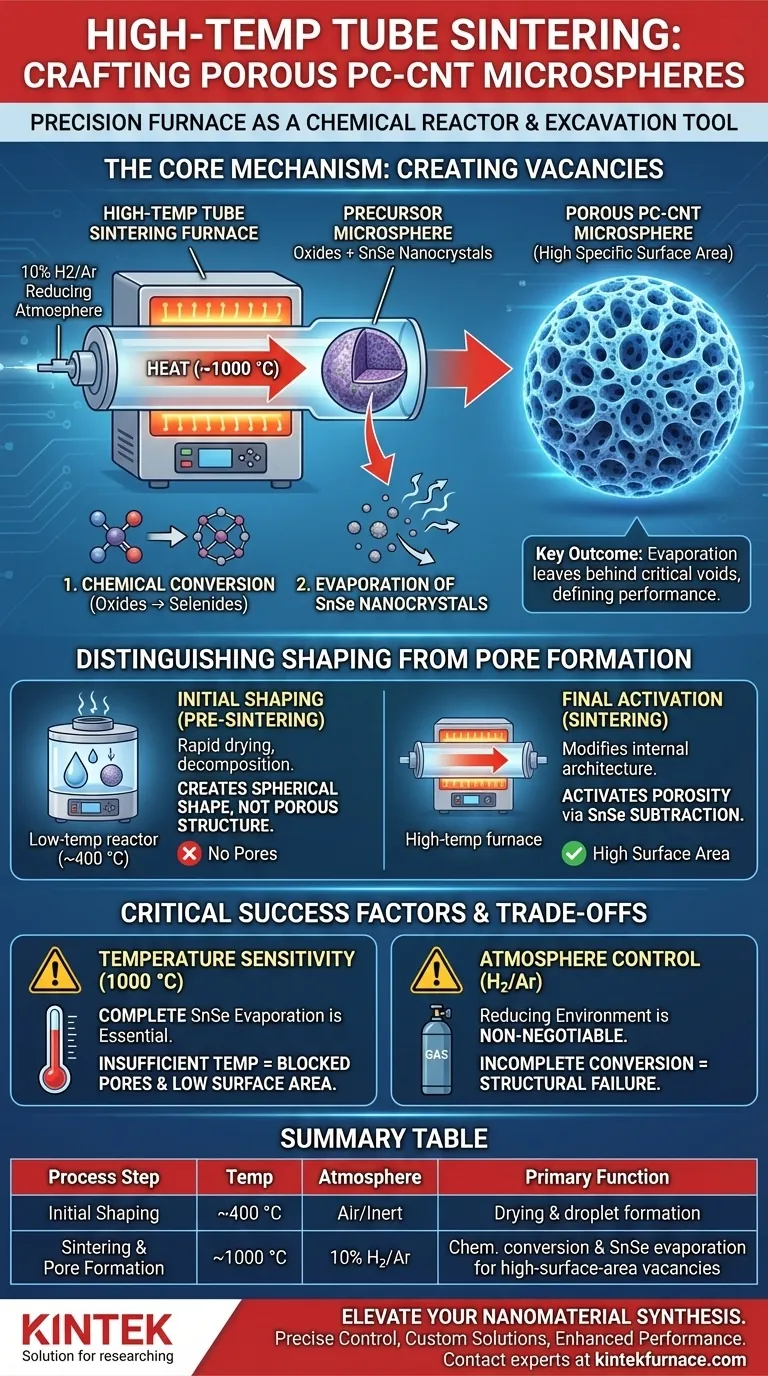

The primary purpose of the high-temperature tube sintering furnace is to act as a precise chemical reactor that converts precursor materials into a highly porous structure. Specifically, it utilizes a temperature of approximately 1000 °C and a reducing atmosphere (10% H2/Ar) to drive the evaporation of sacrificial nanocrystals, leaving behind the critical voids that define the material's performance.

Core Takeaway The furnace performs two simultaneous functions: chemically converting oxides into selenides and physically evaporating SnSe nanocrystals. This evaporation is the specific mechanism that generates vacancies, creating the high specific surface area required for effective PC-CNT microspheres.

The Mechanism of Pore Creation

Chemical Conversion Under Reducing Atmosphere

The furnace provides a controlled environment containing a reducing gas mixture, typically 10% Hydrogen (H2) and Argon (Ar).

Under these conditions, the furnace facilitates the chemical reduction of the precursor materials. Specifically, it converts the oxides present within the initial microspheres into selenides.

Creation of Vacancies via Evaporation

The most critical function of the sintering furnace in this specific workflow is the complete evaporation of SnSe (Tin Selenide) nanocrystals.

The furnace maintains a high temperature (around 1000 °C), which is sufficient to gasify the SnSe components.

As these nanocrystals evaporate and exit the material, they leave behind empty spaces. These "vacancies" become the pores of the final structure, directly resulting in a high specific surface area.

Distinguishing Shaping from Pore Formation

Initial Shaping (Pre-Sintering)

It is important to distinguish the sintering step from the initial formation of the microspheres.

As noted in supplementary contexts, a lower-temperature reactor (often around 400 °C) is used for the rapid drying and thermal decomposition of spray droplets. This stage creates the spherical shape but does not create the final porous nanostructure.

Final Activation (Sintering)

The high-temperature tube sintering furnace is responsible for the "activation" of the material's porosity.

While the initial shape is set earlier, the sintering furnace modifies the internal architecture. It transforms a dense or semi-dense sphere into a porous, high-surface-area functional material through the subtraction of the SnSe component.

Understanding the Trade-offs

Temperature Sensitivity

The process relies on a delicate thermal balance. The temperature must be high enough (approx. 1000 °C) to ensure the complete evaporation of SnSe.

If the temperature is insufficient, residual SnSe may remain within the carbon matrix. This would block potential pores, significantly reducing the specific surface area and the material's effectiveness.

Atmosphere Control

The reducing atmosphere is non-negotiable. Without the presence of H2/Ar, the conversion from oxides to selenides may fail or be incomplete.

Incomplete conversion prevents the formation of the specific selenide phases required for the subsequent evaporation step, ultimately leading to a structural failure of the PC-CNT microspheres.

Making the Right Choice for Your Goal

To maximize the quality of porous carbon nanotube microspheres, apply the following principles:

- If your primary focus is Surface Area: Ensure the furnace reaches and maintains the full 1000 °C target to guarantee the total evaporation of all SnSe nanocrystals.

- If your primary focus is Chemical Purity: Strictly monitor the H2/Ar ratio to ensure complete reduction of oxides before the evaporation phase occurs.

- If your primary focus is Morphology: Verify that the initial shaping (at ~400 °C) is successful before subjecting the material to the high-temperature sintering process.

Success in this process depends on using the furnace not just as a heater, but as an excavation tool that uses heat to remove material and build internal space.

Summary Table:

| Process Step | Temperature | Atmosphere | Primary Function |

|---|---|---|---|

| Initial Shaping | ~400 °C | Air/Inert | Drying & thermal decomposition of droplets into microspheres. |

| Sintering/Selenization | ~1000 °C | 10% H2/Ar | Chemical reduction of oxides to selenides. |

| Pore Formation | ~1000 °C | 10% H2/Ar | Evaporation of SnSe nanocrystals to create high-surface-area vacancies. |

Elevate Your Nanomaterial Synthesis with KINTEK

Precise temperature control and atmosphere integrity are critical for successful PC-CNT microsphere production. KINTEK provides industry-leading high-temperature Tube, Muffle, and Vacuum furnace systems designed to meet the rigorous demands of chemical vapor deposition (CVD) and advanced sintering.

Why Choose KINTEK?

- Expert R&D & Manufacturing: Our systems ensure the thermal stability required for complete SnSe evaporation at 1000 °C.

- Customizable Solutions: Whether you need specific gas mixing for H2/Ar atmospheres or specialized tube dimensions, we tailor our equipment to your unique lab needs.

- Enhanced Material Performance: Achieve higher specific surface areas and superior chemical purity with our precision-engineered heating solutions.

Ready to optimize your porous carbon nanotube production? Contact our experts today to find your perfect furnace solution!

Visual Guide

References

- Hyo Yeong Seo, Gi Dae Park. Engineering Porous Carbon Nanotube Microspheres with Nickel Sulfoselenide Nanocrystals for High‐Performance Potassium‐Ion Batteries: Electrochemical Mechanisms and Cycling Stability. DOI: 10.1002/sstr.202500222

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the future of zoned furnace systems? Smarter, Adaptive, and Energy-Efficient Solutions

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- What are the advantages of a dual-zone tube furnace for Ti3C2Tx MXene? Master Precise Sulfurization Kinetics

- What materials and processes is an atmosphere tube furnace suitable for? Unlock Precise Heat Treatment Solutions

- Why is thermal uniformity important in a drop tube furnace? Ensure Reliable Results and Consistent Processes

- What are the maintenance requirements for an alumina tube furnace? Ensure Longevity and Accuracy in Your Lab

- In what settings are both tube and box furnaces commonly used? Optimize Your Thermal Processes with the Right Choice

- What role does a single-zone tube furnace play in the synthesis of (100)-oriented MoO2 nanobelts? Precision APCVD Control