In short, the future of zoned furnace systems is smarter, more adaptive, and deeply integrated. These systems are evolving beyond simple thermostats and dampers into intelligent networks that use IoT connectivity, machine learning, and hybrid technologies to optimize both comfort and energy consumption with minimal human input.

The core evolution is a shift from static, manually-configured zoning to a dynamic, self-optimizing climate system. The goal is no longer just to heat or cool different rooms independently, but to create a system that anticipates needs, learns patterns, and makes predictive adjustments to maximize efficiency.

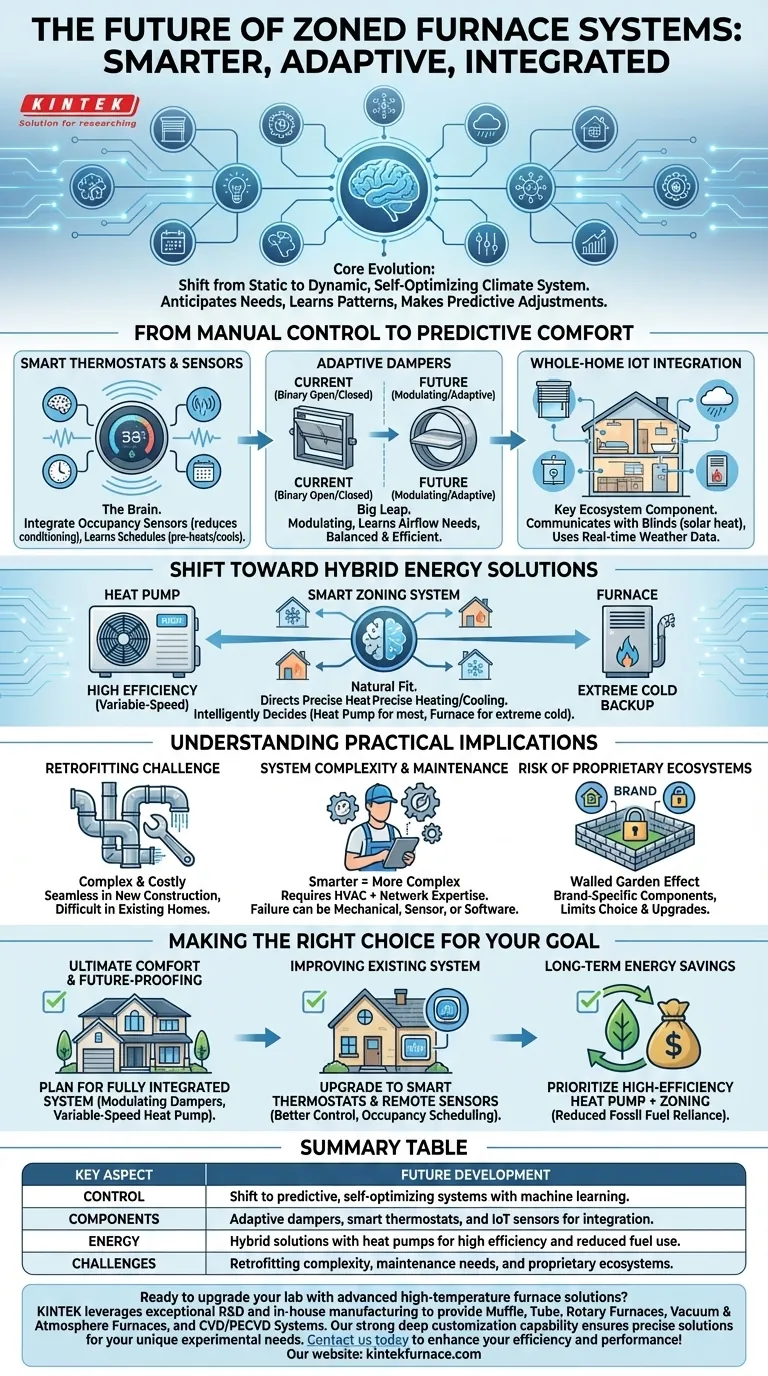

From Manual Control to Predictive Comfort

The most significant advancements in zoning technology are focused on making the system "think" for itself. This move away from manual setpoints toward automated, intelligent operation is the central theme of its future.

The Role of Smart Thermostats and Sensors

Modern smart thermostats are the brain of the future zoned system. Their role extends far beyond remote temperature control.

They integrate occupancy sensors to determine which zones are in use, automatically reducing conditioning in empty rooms. By learning your household's daily and weekly schedules, they can pre-heat or pre-cool zones just before you need them.

The Rise of Adaptive Dampers

The biggest leap forward will be in the dampers themselves. Current systems use binary "open" or "closed" dampers, which can create pressure imbalances and inefficient airflow.

Future systems will feature adaptive or modulating dampers. These dampers can open partially, learning over time exactly how much conditioned air a specific zone needs to maintain its setpoint. This ensures a more balanced, efficient, and quiet operation.

Whole-Home IoT Integration

Future zoning won't exist in a silo. It will be a key component of a fully integrated smart home ecosystem.

Imagine your zoned system communicating with smart window blinds, automatically closing them on a sunny wall to reduce solar heat gain and ease the load on the A/C in that zone. It could also pull real-time weather data to pre-condition the home ahead of a heatwave or cold snap.

The Shift Toward Hybrid Energy Solutions

As the world moves toward electrification, the furnace itself is part of the evolution. Zoning is a critical enabling technology for the next generation of high-efficiency heating and cooling.

Why Zoning and Heat Pumps Are a Natural Fit

Heat pumps are incredibly efficient, but their performance can vary with extreme outdoor temperatures. Pairing a variable-speed heat pump with a smart zoning system creates a powerful combination.

Zoning allows the system to direct the precise amount of heating or cooling exactly where it is needed, maximizing the heat pump's efficiency. In a hybrid setup, the system can intelligently decide to use the furnace for a specific zone only during the most extreme cold, relying on the heat pump the rest of the time.

Understanding the Practical Implications

While the future is promising, it's essential to understand the real-world trade-offs and challenges that come with increasing technological complexity.

The Challenge of Retrofitting

Implementing these advanced systems is most seamless in new construction. Retrofitting a home with modulating dampers and the necessary sensors can be complex and costly, often requiring significant modifications to existing ductwork.

System Complexity and Maintenance

As systems become smarter, they also become more complex. Diagnosis and repair will require technicians who are proficient in both HVAC mechanics and network diagnostics. A failure could stem from a mechanical damper, a faulty sensor, or a software glitch.

The Risk of Proprietary Ecosystems

Many manufacturers are developing their own integrated systems. This can lead to a "walled garden" effect, where a specific brand of smart thermostat may only work with that same brand's dampers and control board, limiting consumer choice and future upgrade paths.

Making the Right Choice for Your Goal

As you consider this technology, align your decision with your primary objective.

- If your primary focus is ultimate comfort and future-proofing a new home: Plan for a fully integrated system with modulating dampers and a compatible, variable-speed heat pump from the start.

- If your primary focus is improving an existing system: Start by upgrading to smart thermostats with remote sensors to gain better control and occupancy-based scheduling for your current zones.

- If your primary focus is long-term energy savings: Prioritize the combination of a high-efficiency heat pump with a zoning system to dramatically reduce your reliance on fossil fuels.

Ultimately, the future of home zoning is about creating an invisible, intelligent system that delivers perfect comfort with maximum efficiency.

Summary Table:

| Key Aspect | Future Development |

|---|---|

| Control | Shift to predictive, self-optimizing systems with machine learning |

| Components | Adaptive dampers, smart thermostats, and IoT sensors for integration |

| Energy | Hybrid solutions with heat pumps for high efficiency and reduced fuel use |

| Challenges | Retrofitting complexity, maintenance needs, and proprietary ecosystems |

Ready to upgrade your lab with advanced high-temperature furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance your efficiency and performance!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- How does a multi-zone tube furnace achieve precise temperature gradient control? Master MoS2 Isotope Monolayer Synthesis

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations