At its core, thermal uniformity in a drop tube furnace is the single most important factor for achieving reliable and reproducible results. It ensures that every particle of a material moving through the furnace experiences the exact same temperature profile, which is the foundation for any valid scientific experiment or consistent industrial process. Without it, you are introducing a critical, uncontrolled variable that invalidates your outcomes.

The goal of a drop tube furnace is to subject a material to a precise, repeatable thermal event. Poor thermal uniformity means this event is inconsistent, making your research results unreliable and your production output unpredictable.

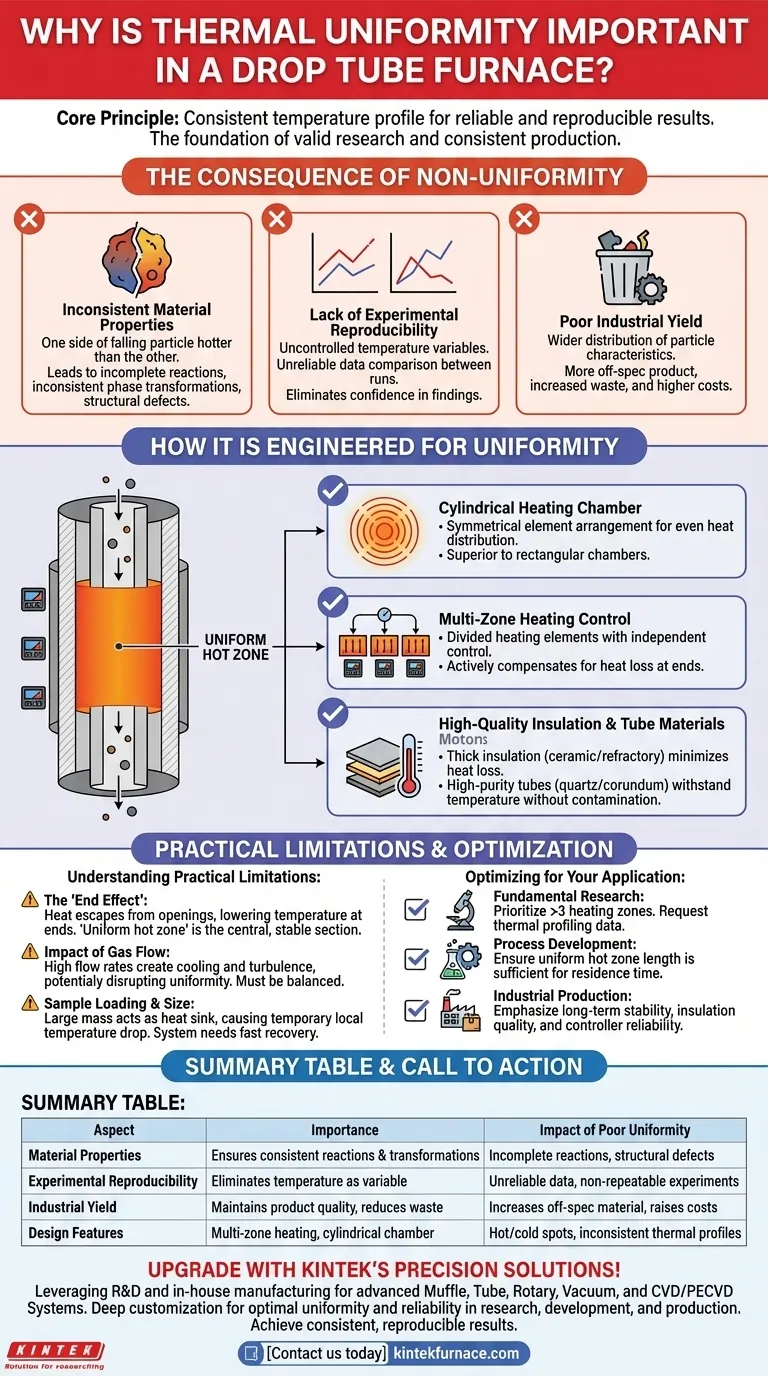

The Consequence of Non-Uniformity

A drop tube furnace uses gravity to pass material through a vertical, high-temperature tube. The entire purpose is to control the material's thermal history. Non-uniformity directly undermines this control.

Inconsistent Material Properties

If the temperature varies across the diameter of the tube, one side of a falling particle will be hotter than the other. This can lead to incomplete chemical reactions, inconsistent phase transformations, or structural defects in the final material.

Lack of Experimental Reproducibility

In a research setting, the ability to reproduce an experiment is paramount. If the thermal zone has hot or cold spots that fluctuate between runs, you cannot reliably compare data. Thermal uniformity eliminates temperature as an uncontrolled variable, ensuring your results are due to the factors you are intentionally studying.

Poor Industrial Yield

For industrial applications like powder synthesis or heat treatment, uniformity is directly tied to product quality and yield. Inconsistent heating leads to a wider distribution of particle characteristics, meaning more of the batch falls outside of specification, increasing waste and cost.

How a Drop Tube Furnace Is Engineered for Uniformity

Achieving a stable and uniform hot zone is a primary design goal. This is accomplished through the careful integration of several key components and principles.

The Cylindrical Heating Chamber

The fundamental design of a cylindrical tube provides a natural advantage. Heating elements arranged symmetrically around the tube radiate heat inward evenly, creating a more uniform thermal field compared to a rectangular chamber.

Multi-Zone Heating Control

This is the most critical feature for precision. The furnace's heating elements (often made of silicon carbon or silicon molybdenum rods) are divided into multiple sections along the tube's length. Each zone has its own thermocouple and independent power controller.

This allows the system to actively compensate for heat loss at the ends of the tube, creating a significantly longer and flatter "uniform hot zone" in the center where the process occurs.

High-Quality Insulation and Tube Materials

A thick layer of ceramic or refractory insulation minimizes heat loss to the environment. This stability is crucial for preventing external temperature fluctuations from disturbing the thermal balance inside the furnace.

Furthermore, the process tube itself, typically made of high-purity quartz or corundum (alumina), is chosen for its ability to withstand extreme temperatures without contaminating the sample or reacting with the process atmosphere.

Understanding the Practical Limitations

Perfect thermal uniformity is an ideal. In practice, there are physical constraints and trade-offs to consider when operating a drop tube furnace.

The "End Effect"

Heat inevitably escapes from the top and bottom openings of the furnace tube. Because of this, the temperature at the very ends of the heated section will always be lower than in the center. The "uniform hot zone" refers to the central portion of the furnace where the temperature is stable and meets specification (e.g., ±1°C).

Impact of Gas Flow

Many processes require a controlled atmosphere, involving a continuous flow of inert or reactive gas. A high gas flow rate can introduce turbulence and create a cooling effect, potentially disrupting the thermal uniformity. This must be balanced against the needs of the process.

Sample Loading and Size

Introducing a significant mass of material, especially if it enters at room temperature, can act as a heat sink and cause a temporary local drop in temperature. The furnace's control system and thermal mass must be sufficient to recover quickly from this thermal load.

Optimizing for Your Application

Your approach to thermal uniformity depends on your final goal.

- If your primary focus is fundamental research: Prioritize a furnace with at least three independent heating zones and request thermal profiling data from the manufacturer to verify the length and quality of the uniform hot zone.

- If your primary focus is process development: Ensure the furnace's specified uniform hot zone is long enough to provide the necessary residence time for your material as it falls at its terminal velocity.

- If your primary focus is industrial production: Emphasize the long-term stability of the heating elements, the quality of the insulation, and the reliability of the temperature controllers to maintain consistent output over thousands of hours.

Ultimately, mastering thermal uniformity is equivalent to mastering the outcome of your high-temperature process.

Summary Table:

| Aspect | Importance | Impact of Poor Uniformity |

|---|---|---|

| Material Properties | Ensures consistent chemical reactions and phase transformations | Leads to incomplete reactions and structural defects |

| Experimental Reproducibility | Eliminates temperature as an uncontrolled variable | Results in unreliable data and non-repeatable experiments |

| Industrial Yield | Maintains product quality and reduces waste | Increases off-spec material and raises costs |

| Design Features | Includes multi-zone heating and cylindrical chamber | Causes hot/cold spots and inconsistent thermal profiles |

Upgrade your high-temperature processes with KINTEK's precision solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced drop tube furnaces and other high-temperature systems tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization capabilities to ensure optimal thermal uniformity and reliability. Whether you're in research, process development, or industrial production, KINTEK helps you achieve consistent, reproducible results. Contact us today to discuss how we can enhance your laboratory efficiency and output quality!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing