At its core, an atmosphere tube furnace is designed for the high-temperature heat treatment of a wide range of materials, including metals, ceramics, and composites, within a precisely controlled gaseous environment. Its defining feature is the ability to manipulate the atmosphere inside a sealed tube, allowing for processes that are impossible in open-air furnaces.

The primary value of an atmosphere tube furnace is not just its ability to heat materials, but its power to control chemical reactions. By replacing ambient air with a specific gas, you can prevent unwanted oxidation or intentionally create new material properties.

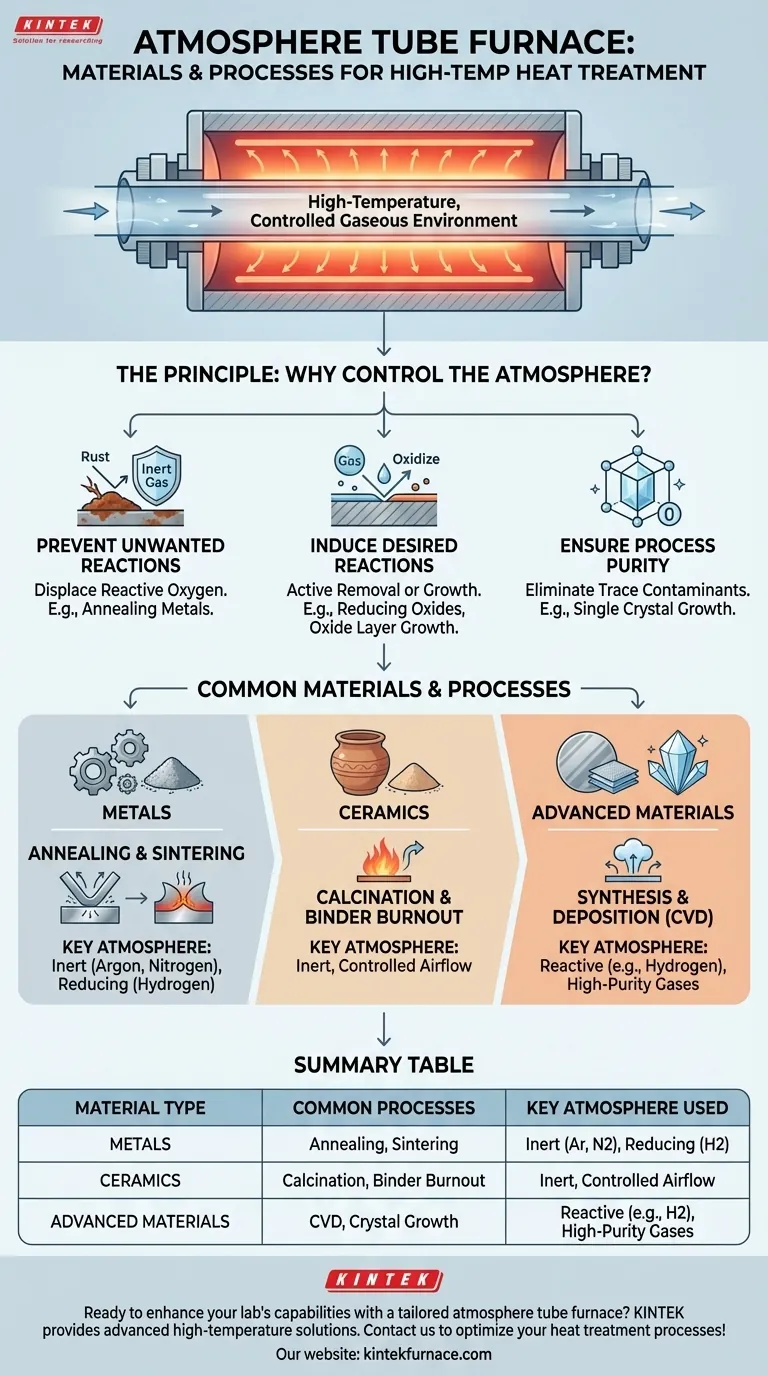

The Principle: Why Control the Atmosphere?

Understanding the purpose of atmospheric control is key to leveraging a tube furnace effectively. At high temperatures, most materials become highly reactive with the oxygen and moisture present in normal air.

To Prevent Unwanted Reactions

Many heat treatment processes, such as annealing metals, are intended to change a material's physical structure, not its chemical composition. Exposing a hot metal to air causes oxidation (rusting or scaling), which degrades its surface and properties.

By flooding the furnace tube with an inert gas like argon or nitrogen, you displace the reactive oxygen, creating a neutral environment that protects the material during heating and cooling.

To Induce Desired Reactions

Conversely, some processes require a specific chemical reaction. A reducing atmosphere, containing gases like hydrogen or carbon monoxide, can be used to actively remove oxides from a material's surface.

An oxidizing atmosphere, with a controlled amount of oxygen, might be used to intentionally grow a specific oxide layer on a semiconductor. This level of control is fundamental to materials engineering.

To Ensure Process Purity

For sensitive applications like growing single crystals or synthesizing advanced nanomaterials, even trace contaminants in the air can ruin the final product.

An atmosphere furnace, when purged and fed with high-purity gas, ensures that the only elements present are the ones you intend, leading to cleaner, more predictable results.

Common Materials and Processes

The furnace's versatility makes it a staple in both research labs and specialized industrial production.

For Metals: Annealing and Sintering

Metals are commonly processed to relieve internal stresses (annealing) or to fuse metal powders into a solid mass (sintering). Both processes require an inert or reducing atmosphere to prevent oxidation and ensure the material's integrity.

For Ceramics: Calcination and Binder Burnout

Creating advanced ceramics often involves heating powders to drive off chemicals and water (calcination) or to burn out organic binders used to shape a part. An atmosphere furnace provides the precise temperature and airflow control needed to manage these off-gassing processes safely and completely.

For Advanced Materials: Synthesis and Deposition

Tube furnaces are critical for cutting-edge processes like Chemical Vapor Deposition (CVD), where gases react at high temperatures to deposit a thin film onto a substrate. They are also used for growing high-purity crystals for the electronics and optics industries.

Understanding the Trade-offs and Limitations

While powerful, an atmosphere tube furnace is not a universal solution. Its design comes with inherent trade-offs that are important to recognize.

Sample Size and Throughput

The primary limitation is sample size. The diameter of the process tube, typically ranging from 1 to 6 inches, restricts the physical dimensions of the parts you can process. This makes them ideal for labs and small-batch production but unsuitable for high-volume manufacturing.

Temperature Uniformity

A tube furnace has a "hot zone" in the center where the temperature is most stable and uniform. The length of this zone is finite. For very long samples or processes requiring exceptional uniformity, specialized multi-zone furnaces may be necessary to compensate for heat loss near the ends of the tube.

Safety with Reactive Gases

While features like over-temperature protection and leak detection are standard, using flammable (hydrogen) or toxic (carbon monoxide) gases requires rigorous safety protocols, proper facility ventilation, and well-trained operators. These gases introduce a higher level of operational risk compared to inert gases.

Making the Right Choice for Your Application

Selecting the correct setup depends entirely on your end goal.

- If your primary focus is fundamental research: A single-zone furnace with reliable temperature and inert gas flow control is often sufficient for studying material properties without oxidation.

- If your primary focus is process development: Prioritize a system with precise mass flow controllers for mixing gases and consider a multi-zone furnace for superior temperature uniformity.

- If your primary focus is high-purity synthesis: Invest in high-quality quartz or alumina tubes, leak-tight fittings, and a system capable of achieving a vacuum to fully purge contaminants before introducing high-purity process gas.

Ultimately, choosing the right equipment begins with a clear understanding of the chemical environment your material requires to achieve its desired state.

Summary Table:

| Material Type | Common Processes | Key Atmosphere Used |

|---|---|---|

| Metals | Annealing, Sintering | Inert (Argon, Nitrogen), Reducing (Hydrogen) |

| Ceramics | Calcination, Binder Burnout | Inert, Controlled Airflow |

| Advanced Materials | CVD, Crystal Growth | Reactive (e.g., Hydrogen), High-Purity Gases |

Ready to enhance your lab's capabilities with a tailored atmosphere tube furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can optimize your heat treatment processes and achieve superior material outcomes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety