In short, maintaining an alumina tube furnace involves a consistent schedule of cleaning, inspection, and calibration. The core tasks are cleaning the alumina tube after each use to prevent contamination, regularly inspecting heating elements and electrical systems for wear, and periodically calibrating temperature sensors to ensure accuracy. Always defer to the specific procedures outlined in your manufacturer's manual.

The goal of furnace maintenance is not just to prevent breakdowns. It is to preserve the two fundamental qualities that make an alumina furnace valuable: its chemical inertness for sample purity and its thermal stability for repeatable, accurate results.

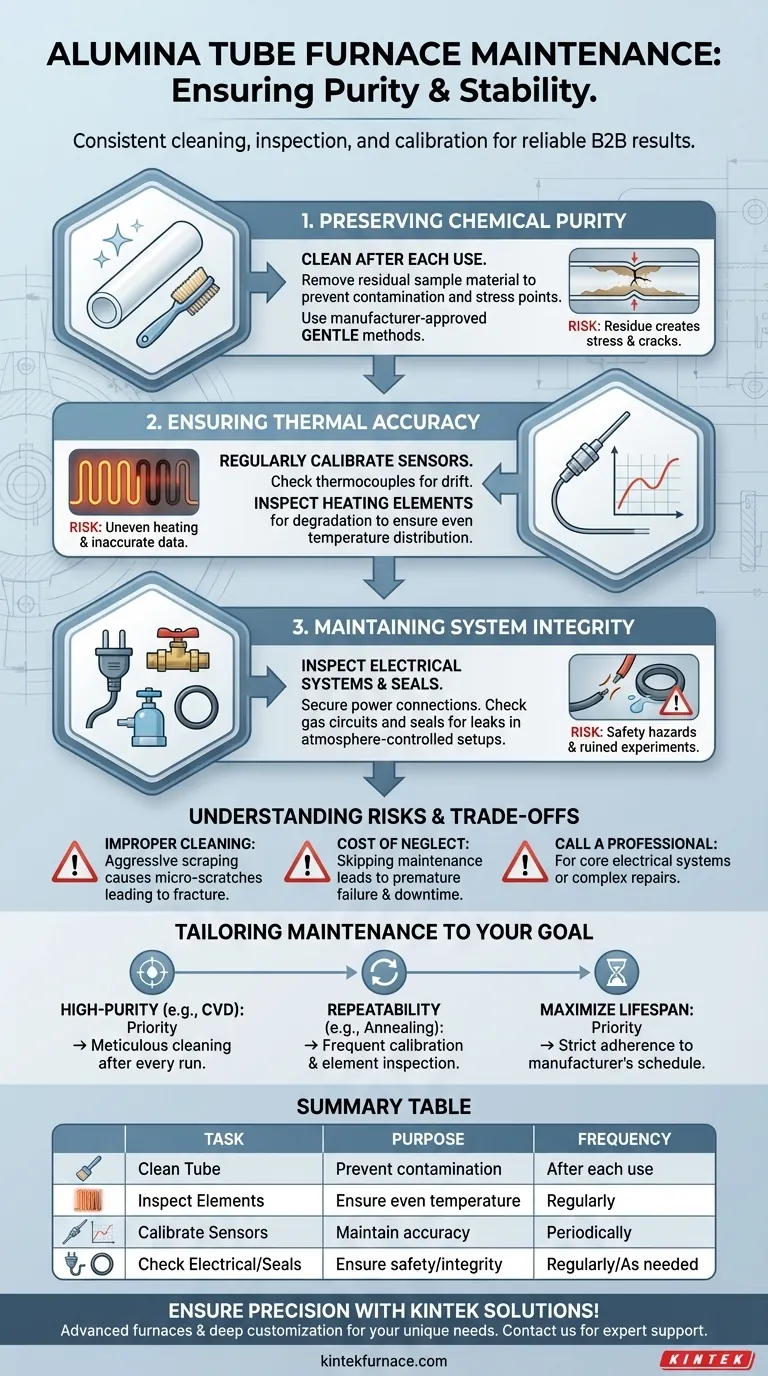

The Core Pillars of Furnace Maintenance

Effective maintenance rests on systematically protecting the key systems of the furnace. Each task is designed to mitigate a specific risk to your equipment's performance and longevity.

Preserving Chemical Purity

The primary benefit of an alumina tube is its excellent chemical resistance at high temperatures. Protecting this feature is your first priority.

After every use, you must ensure the inside of the tube is completely clean. Any residual sample material can contaminate future experiments or, worse, cause mechanical stress.

When heated, different materials expand at different rates. Leftover residue can create localized stress points on the tube wall, potentially leading to cracks and catastrophic failure at high temperatures. Cleaning may involve gentle brushing or scraping, always following manufacturer-approved methods.

Ensuring Thermal Accuracy

An experiment is only as good as its data. Inaccurate temperature readings lead to unreliable and unrepeatable results.

Regular calibration of temperature sensors, such as thermocouples, is critical. Over time, these sensors can drift, providing false readings. This check ensures your setpoint temperature is the actual temperature inside the furnace.

You must also ensure even temperature distribution. Regularly inspect the heating elements for any signs of degradation or damage, as this can create hot or cold spots along the tube.

Maintaining System Integrity

A furnace is more than its tube; it is an integrated system of electrical and atmospheric components.

Regularly inspect the power supply and all electrical connections to ensure they are secure and free from damage. This is a fundamental safety and operational check.

If you use the furnace for applications requiring a specific atmosphere (e.g., inert gas or vacuum), you must check the integrity of all seals and gas circuits. Leaks can ruin experiments and, in some cases, create safety hazards.

Understanding the Trade-offs and Risks

While maintenance is essential, performing it incorrectly can cause more harm than good. Understanding the risks is key to protecting your investment.

The Risk of Improper Cleaning

Never use overly aggressive cleaning methods. Scraping the alumina tube with hard metal tools can create micro-scratches on the surface. These scratches act as stress concentrators, dramatically increasing the risk of the tube fracturing during a thermal cycle.

The Cost of Neglect

Skipping maintenance has cascading consequences. Minor issues like sensor drift lead to bad data, while ignoring a degrading heating element will eventually lead to premature failure, costly repairs, and significant downtime.

When to Call a Professional

Routine cleaning and inspection can be performed by a trained operator. However, any work involving the furnace's core electrical systems or complex repairs should be handled by a qualified technician or the manufacturer. The complex and precise nature of this equipment demands expert knowledge for significant interventions.

Tailoring Maintenance to Your Goal

Your specific application should guide your maintenance priorities.

- If your primary focus is high-purity material synthesis (e.g., CVD): Your priority is meticulous tube cleaning after every run to prevent cross-contamination between samples.

- If your primary focus is repeatable thermal processing (e.g., annealing): Your priority is frequent temperature sensor calibration and heating element inspection to guarantee process consistency.

- If your primary focus is maximizing equipment lifespan: Your priority is adhering to a strict, documented schedule of all inspection, cleaning, and preventative maintenance tasks as defined by the manufacturer.

Ultimately, consistent maintenance is a direct investment in the reliability and accuracy of your work.

Summary Table:

| Maintenance Task | Purpose | Frequency |

|---|---|---|

| Clean alumina tube | Prevent contamination and stress cracks | After each use |

| Inspect heating elements | Ensure even temperature distribution | Regularly |

| Calibrate temperature sensors | Maintain thermal accuracy | Periodically |

| Check electrical systems | Ensure safety and operational integrity | Regularly |

| Inspect seals and gas circuits | Prevent leaks in atmosphere-controlled setups | As needed |

Ensure your lab's precision and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Tube Furnaces, Muffle Furnaces, and more, all backed by strong deep customization to meet your unique needs. Don't let maintenance issues disrupt your experiments—contact us today for expert support and reliable equipment tailored to your goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing