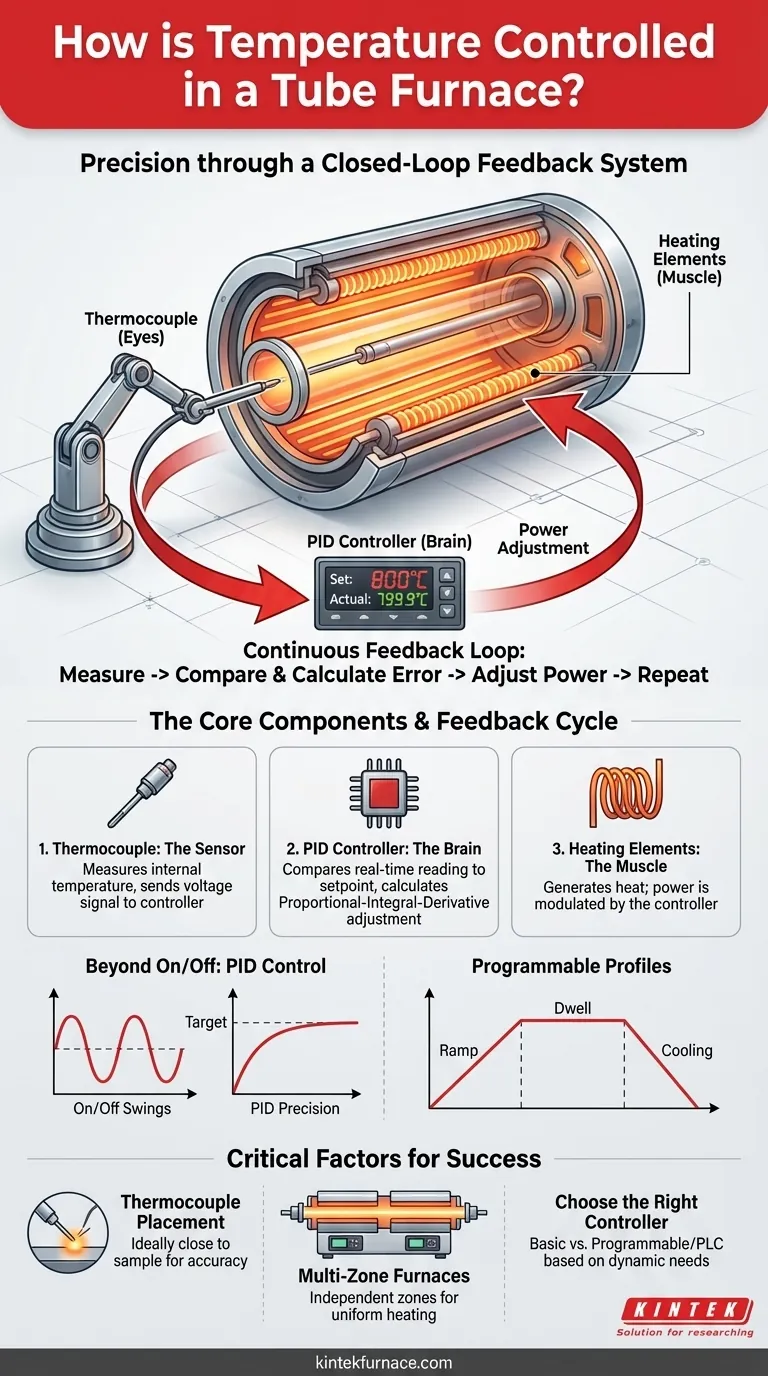

At its core, temperature control in a tube furnace is achieved through a precise, closed-loop feedback system. This system constantly measures the internal temperature using a sensor, compares it to the desired temperature you have set, and intelligently adjusts the power sent to the heating elements to eliminate any difference. The primary components are a thermocouple, a temperature controller, and the heating elements themselves.

A tube furnace doesn't just apply heat; it executes a precise thermal command. The system functions as a continuous feedback loop where a sensor (the thermocouple) acts as the "eyes," and a digital controller (the "brain") uses that information to manage the heating elements with high accuracy.

The Core Components of Temperature Control

To understand how a furnace maintains a set temperature to within a single degree, you must first understand the role of each component in the system. They work in a tightly coordinated cycle.

The Thermocouple: The Eyes of the System

A thermocouple is the temperature sensor. It's a simple, robust probe made of two different metals joined at one end. When this junction is heated, it generates a tiny voltage that corresponds directly to the temperature, which the controller can read with extreme accuracy.

The Controller: The Brain of the Operation

The temperature controller is the central processing unit. It performs one critical task: comparing the real-time temperature reading from the thermocouple to the target temperature (the "setpoint") that the user has programmed.

Most modern furnaces use a PID controller, which stands for Proportional-Integral-Derivative. This isn't just a simple on/off switch; it's a sophisticated algorithm that anticipates how the furnace will behave to prevent overshooting or undershooting the target temperature.

The Heating Elements: The Muscle

The heating elements are the components that actually generate the heat. The controller manages the power supplied to these elements. Based on its PID calculations, the controller will modulate the power to heat up quickly, maintain a steady temperature, or cool down at a controlled rate.

How the Feedback Loop Creates Precision

The true precision of a tube furnace comes not from the individual components, but from how they interact in a continuous, high-speed loop.

A Continuous Cycle of Measurement and Adjustment

The process is a constant cycle:

- The thermocouple measures the current temperature inside the furnace.

- It sends this information to the controller.

- The controller calculates the error—the difference between the measured temperature and your setpoint.

- The controller then adjusts the power to the heating elements to correct this error.

This loop repeats many times per second, resulting in exceptionally stable temperature maintenance.

Beyond On/Off: The Power of PID

A simple thermostat, like in a home oven, turns fully on when it's too cold and fully off when it's too hot, leading to wide temperature swings. A PID controller is far more intelligent.

It considers the Proportional (current error), Integral (past, accumulated error), and Derivative (predicted future error) to make nuanced adjustments. This allows it to "ease off" the power as it approaches the setpoint, preventing overshoot and creating a smooth, stable thermal environment.

Programmable Ramping and Dwelling

Advanced controllers allow you to program multi-step temperature profiles. You can define a ramp rate (e.g., "heat at 10°C per minute"), a dwell time (e.g., "hold at 800°C for two hours"), and subsequent cooling steps. This programmability is essential for materials science, annealing, and other complex thermal processes.

Understanding the Trade-offs and Pitfalls

While the control system is robust, its effectiveness depends on proper setup and an understanding of its limitations.

Simple vs. Programmable Controllers

A basic digital controller allows you to set one temperature and hold it. A programmable PID or PLC controller offers multi-step recipe control. Choosing the right one depends entirely on whether your process is static or requires a dynamic thermal profile.

The Critical Role of Thermocouple Placement

The controller only knows what the thermocouple tells it. If the thermocouple is placed near a heating element, it will read a higher temperature than your sample experiences. For best results, the thermocouple tip should be placed as close to the sample as is safely possible to ensure the control system is regulating the correct temperature.

Single-Zone vs. Multi-Zone Furnaces

For longer tube furnaces, a single set of heating elements can create temperature gradients, where the center is hotter than the ends. To combat this, multi-zone furnaces use two or more independent heating zones, each with its own thermocouple and controller loop. This allows for an exceptionally uniform heated length, which is critical for growing crystals or processing larger batches.

Making the Right Choice for Your Goal

The level of temperature control you need is dictated by your application.

- If your primary focus is basic, stable heating to a single temperature: A standard digital furnace with a single-zone PID controller is perfectly sufficient and cost-effective.

- If your primary focus is complex material processing or annealing: You require a furnace with a fully programmable, multi-step PID controller to define precise ramp and dwell profiles.

- If your primary focus is maximum temperature uniformity over a large sample: A multi-zone furnace with independent controllers for each zone is the only way to guarantee a flat thermal profile.

Ultimately, understanding this control system empowers you to select the right tool and operate it for precise, repeatable results.

Summary Table:

| Component | Role | Key Function |

|---|---|---|

| Thermocouple | Temperature Sensor | Measures internal temperature and sends data to the controller |

| PID Controller | Central Processor | Compares measured vs. setpoint temperature and adjusts power using algorithms |

| Heating Elements | Heat Generator | Produce heat based on controller's power adjustments for precise control |

Ready to elevate your lab's precision with advanced tube furnaces? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior temperature control and efficiency. Contact us today to discuss how our tailored furnace solutions can optimize your thermal processes and drive better results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing