To improve the uniform length of a tube furnace, the most effective strategies involve adding insulation plugs and increasing the number of independent heating zones. These methods directly address the primary cause of temperature variation—heat loss at the ends of the tube—by physically containing heat and actively compensating for temperature drops.

Achieving a longer uniform temperature zone is fundamentally about counteracting inevitable heat loss at the tube's ends. This is best accomplished by using physical barriers (insulation plugs) to retain heat and multiple, independently controlled heating zones to actively compensate for temperature drops.

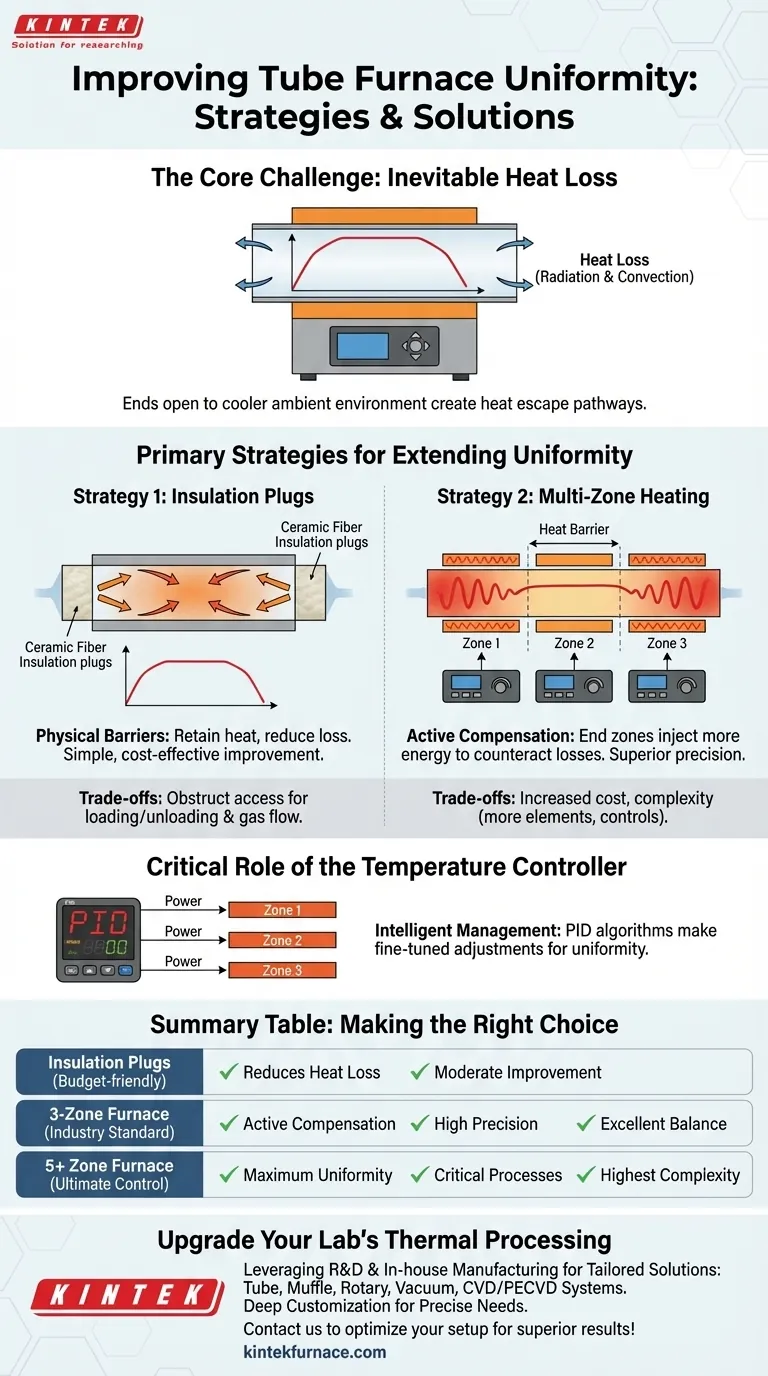

The Core Challenge: Inevitable Heat Loss

Why Temperature Drops at the Ends

The central problem is that the ends of a furnace tube are open to the cooler, ambient environment. This creates a natural pathway for heat to escape via radiation and convection.

As a result, the temperature profile of a simple furnace is never flat. It peaks in the center and slopes downward toward each end, limiting the uniform length—the area where temperature is stable and consistent.

Primary Strategies for Extending Uniformity

Strategy 1: Using Insulation Plugs

The simplest and often most cost-effective first step is to install insulation plugs at the ends of the process tube.

These plugs are typically made of ceramic fiber or other high-temperature insulating materials. They act as physical barriers that reflect heat back into the furnace and significantly reduce the amount of heat lost to the outside air.

While simple, this method can create a noticeable improvement in the length of the uniform zone by trapping heat where it would otherwise escape.

Strategy 2: Increasing the Number of Heating Zones

For more precise control, the superior solution is a multi-zone furnace.

A standard single-zone furnace has one set of heating elements managed by a single controller. It cannot compensate for the natural heat loss at the ends.

A three-zone furnace, the most common multi-zone configuration, has three independent sets of heating elements and controllers. The two smaller end zones can be programmed to a higher temperature than the large central zone.

This allows the end zones to actively inject more energy, creating a "heat barrier" that counteracts losses and flattens the temperature profile across a much longer section of the tube. Furnaces can have five or more zones for even greater precision.

The Critical Role of the Temperature Controller

A multi-zone design is only effective when paired with an advanced temperature controller, often using a PID (Proportional-Integral-Derivative) algorithm.

This control system intelligently manages the power output to each zone, making constant, fine-tuned adjustments to maintain the desired temperature profile. Without a sophisticated controller, managing multiple zones to achieve uniformity would be nearly impossible.

Understanding the Trade-offs

Insulation Plugs: Simplicity vs. Access

Insulation plugs are inexpensive and highly effective for their cost. However, they can obstruct access to the process tube.

This may complicate the loading and unloading of samples or interfere with processes that require a continuous gas flow or atmospheric control.

Multi-Zone Furnaces: Precision vs. Complexity

A multi-zone furnace offers unparalleled control over the temperature profile, making it essential for sensitive applications.

The trade-off is a significant increase in cost and complexity. Each additional zone requires more heating elements, wiring, and sophisticated control hardware, making the system more expensive to purchase and potentially more complex to program.

Making the Right Choice for Your Application

Choosing the right strategy depends entirely on the precision your process requires and your operational constraints.

- If your primary focus is budget and a moderate improvement: Start with a single-zone furnace and add high-quality insulation plugs.

- If your primary focus is high-quality, reproducible results: A three-zone furnace is the industry standard, offering an excellent balance of performance and cost.

- If your primary focus is maximum uniformity for critical processes: A furnace with five or more zones provides the ultimate level of control for the most demanding applications.

Ultimately, aligning your furnace's design with your specific process requirements is the key to achieving reliable and successful outcomes.

Summary Table:

| Strategy | Key Benefit | Ideal For |

|---|---|---|

| Insulation Plugs | Reduces heat loss at ends | Budget-friendly improvements |

| Multi-Zone Heating | Actively compensates for temperature drops | High-precision applications |

Upgrade your lab's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing uniformity and efficiency. Contact us today to discuss how we can optimize your tube furnace setup for superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability