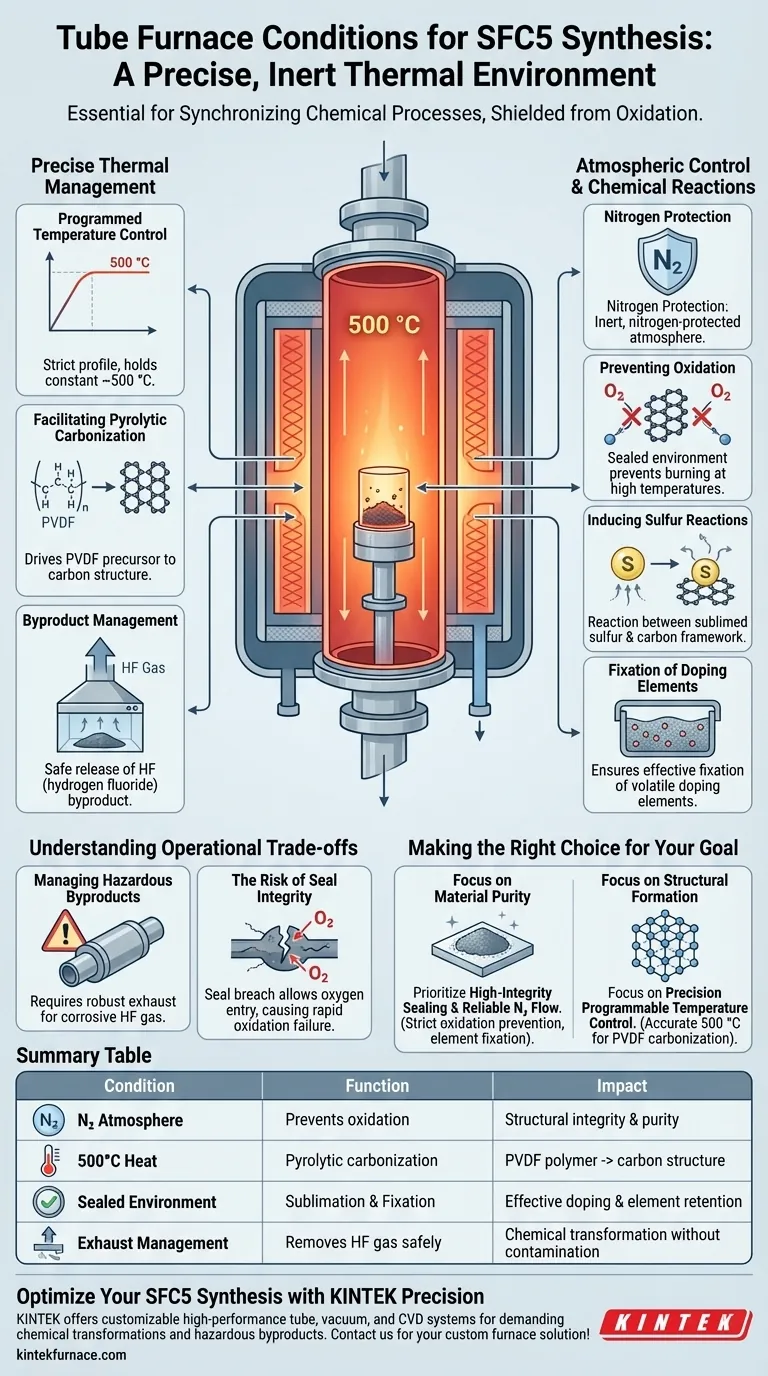

A tube furnace establishes a precise, inert thermal environment essential for the synthesis of SFC5 materials. It primarily provides a sealed, nitrogen-protected atmosphere combined with programmed temperature control to reach approximately 500 °C, ensuring the material undergoes necessary chemical transformations without degrading.

The tube furnace serves as a reactor that synchronizes distinct chemical processes: it facilitates the pyrolytic carbonization of precursors while simultaneously enabling the sublimation and fixation of sulfur within the carbon framework, all shielded from oxidation.

Precise Thermal Management

Programmed Temperature Control

The synthesis of SFC5 relies on strict adherence to a specific temperature profile. The tube furnace utilizes programmed heating to ramp up to and maintain high temperatures, specifically around 500 °C.

Facilitating Pyrolytic Carbonization

This constant high-temperature environment is required to process the precursor material, PVDF. The heat drives the pyrolytic carbonization of the PVDF, converting the polymer into the necessary carbon structure.

Byproduct Management

During this heating phase, the furnace environment accommodates the release of HF (hydrogen fluoride) gas. This release is a critical step in the chemical transformation of the PVDF precursor.

Atmospheric Control and Chemical Reactions

Nitrogen Protection

A defining feature of the tube furnace in this application is its ability to maintain a nitrogen-protected atmosphere. This inert environment is non-negotiable for preserving the integrity of the material.

Preventing Oxidation

Because the synthesis occurs at high temperatures, carbon materials are highly susceptible to burning or degrading if exposed to oxygen. The sealed atmosphere prevents the oxidation of carbon materials, ensuring the structural framework remains intact.

Inducing Sulfur Reactions

The controlled environment facilitates complex chemical interactions beyond simple heating. It induces a reaction between sublimed sulfur and the newly formed carbon framework.

Fixation of Doping Elements

The sealed nature of the system ensures that volatile elements do not simply escape. It ensures the effective fixation of doping elements into the material structure, which is vital for the final properties of the SFC5 material.

Understanding the Operational Trade-offs

Managing Hazardous Byproducts

While the tube furnace effectively facilitates the release of HF gas, this creates a secondary challenge. HF is highly corrosive and toxic, meaning the furnace's exhaust system must be robust enough to handle this byproduct safely.

The Risk of Seal Integrity

The success of the synthesis hinges entirely on the "sealed atmosphere control system." Any breach or leakage in the tube seals will immediately introduce oxygen, leading to the rapid oxidation of the carbon framework and failure of the synthesis.

Making the Right Choice for Your Goal

To ensure high-quality SFC5 synthesis, you must prioritize specific capabilities of your tube furnace based on your process needs:

- If your primary focus is Material Purity: Prioritize a furnace with a high-integrity sealing system and reliable nitrogen flow to strictly prevent oxidation and ensure doping element fixation.

- If your primary focus is Structural Formation: Focus on the precision of the programmable temperature controller to ensure the 500 °C target is held constantly for effective PVDF carbonization.

Success in SFC5 synthesis requires viewing the tube furnace not just as a heater, but as a sealed chemical reactor that balances pyrolysis, sublimation, and doping simultaneously.

Summary Table:

| Condition | Function in SFC5 Synthesis | Impact on Material |

|---|---|---|

| Nitrogen Atmosphere | Prevents oxidation of carbon framework | Ensures structural integrity and purity |

| 500°C Programmed Heat | Facilitates pyrolytic carbonization of PVDF | Converts polymer into carbon structure |

| Sealed Environment | Enables sublimation and fixation of sulfur | Ensures effective doping and element retention |

| Exhaust Management | Safely removes HF (hydrogen fluoride) gas | Allows chemical transformation without contamination |

Optimize Your SFC5 Synthesis with KINTEK Precision

Achieving the perfect balance of nitrogen-protected atmosphere and precise thermal management is critical for SFC5 material integrity. KINTEK offers high-performance tube, vacuum, and CVD systems designed to handle demanding chemical transformations and hazardous byproducts like HF gas.

Backed by expert R&D and manufacturing, our lab high-temperature furnaces are fully customizable to meet your unique research needs, ensuring reliable sulfur fixation and carbonization. Ready to upgrade your material synthesis? Contact KINTEK today to find your custom furnace solution!

Visual Guide

References

- Jianjiao Wang. An S-Infused/S, F-Codoped PVDF-Derived Carbon as a High-Performance Anode for Sodium-Ion Batteries. DOI: 10.3390/ma18174018

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is atmosphere control critical for lignin carbonization? Expert Tips for High-Temperature Tube Furnace Success

- How does an atmosphere-controlled tube furnace contribute to the carbonization of In2O3/C? Optimize Your Composites

- What does 'single zone' mean in a Split Tube Furnace? Unlock Uniform Heating for Your Lab

- Why is precise temperature control important in split tube furnaces? Ensure Reliable Material Processing

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency

- Why is it important to calibrate the temperature profile of a tube furnace? Ensure Accurate and Repeatable Results

- Why is a high-performance tube furnace required for chemical activation? Achieve Precision Pore Control at 700°C

- Why Use a High-Precision Weighing System with a Tube Furnace for Magnetite Oxidation Kinetics? Achieve Real-Time Data.