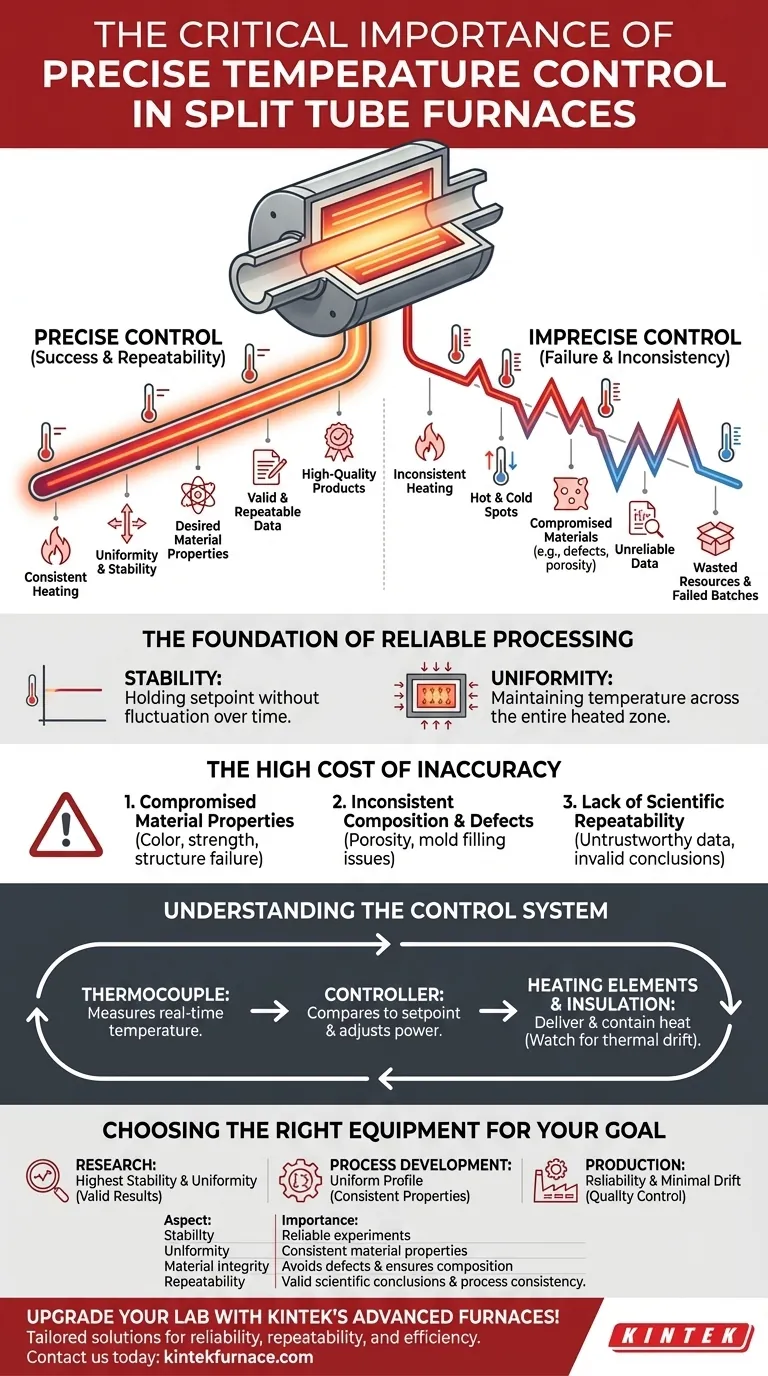

In a split tube furnace, precise temperature control is the non-negotiable foundation for achieving reliable and repeatable material processing. This precision ensures that materials are heated consistently and accurately, a critical requirement for scientific processes like synthesis, sintering, and annealing. Without it, the structural, chemical, and physical properties of the final product are left to chance.

The core issue isn't just about reaching a target temperature; it's about maintaining that temperature with absolute stability and uniformity. In material science, temperature inconsistency is a direct cause of failed experiments, inconsistent product quality, and wasted resources.

The Critical Role of Temperature in Material Transformation

At its core, a split tube furnace is designed to create a controlled thermal environment for transforming materials. Precise control is what makes this transformation predictable and successful.

Why Temperature Is the Master Variable

Processes like annealing (to relieve internal stresses), sintering (to fuse particles together), and synthesis (to create new compounds) are fundamentally dependent on specific temperature-time profiles.

A deviation of even a few degrees can be the difference between a properly formed crystal structure and an amorphous failure, or between a strong, dense ceramic and a brittle, porous one.

Defining "Precise Control"

True temperature precision involves two distinct elements:

- Stability: The ability of the furnace to hold a setpoint over time without fluctuation.

- Uniformity: The ability to maintain the same temperature across the entire length of the heated zone, preventing hot or cold spots.

Failure in either of these areas means the sample is not being processed under the intended conditions, invalidating the results.

The High Cost of Temperature Inaccuracy

When temperature control is poor, the consequences are direct and costly. The integrity of the work—whether in a research lab or a production facility—is immediately compromised.

Compromised Material Properties

Inaccurate heating leads to inconsistent results. For sensitive materials like dental ceramics, temperature variations can alter color, transparency, strength, and thermal expansion.

This can result in clinical failures, such as fractures or discoloration, because the material's properties do not meet specifications.

Inconsistent Composition and Defects

In metallurgy and alloy development, precise temperature regulation is essential for achieving the desired chemical composition and mechanical properties.

Poor control can lead to defects like porosity, prevent efficient mold filling during casting, and ultimately degrade the quality of the final product.

Lack of Scientific Repeatability

For a researcher, the ability to repeat an experiment and achieve the same result is paramount. If the temperature varies between runs, it becomes impossible to isolate the effects of other variables.

Unreliable temperature control makes experimental data untrustworthy and scientific conclusions invalid.

Understanding the Control System

Achieving precision is a function of the entire furnace system working in harmony. The quality of each component directly impacts the final result.

The Thermocouple Feedback Loop

The thermocouple is the system's nerve ending. It constantly measures the temperature inside the furnace and sends this data to the temperature controller.

The controller then compares this real-time temperature to the user's setpoint and adjusts the power sent to the heating elements. A high-quality thermocouple and a responsive controller are the heart of a precise system.

Heating Element Performance

Heating elements, often made of resistance wire, are the source of the heat. However, over time, these elements can experience thermal drift, meaning their heating properties change.

This drift can cause the actual temperature to deviate from the setpoint. A well-designed system mitigates this, but it is a factor that requires monitoring.

The Importance of Quality Insulation

Effective insulation, typically made of ceramic fiber, is critical for reducing heat loss to the surrounding environment.

Good insulation helps maintain a stable internal temperature, improves uniformity along the tube, and reduces the energy required to hold the setpoint. This makes the system more stable and efficient.

Making the Right Choice for Your Application

The level of precision you require depends directly on your final goal. Understanding this will help you select the right equipment and set the right parameters.

- If your primary focus is fundamental research: You need the highest degree of stability and uniformity to ensure your experimental results are valid, defensible, and repeatable.

- If your primary focus is process development (e.g., annealing): Your priority should be a uniform temperature profile across the entire heating zone to guarantee consistent material properties throughout the sample.

- If your primary focus is quality control or small-scale production: Your goal is reliability and minimal thermal drift over time to reduce defects, prevent material waste, and ensure consistent product quality from batch to batch.

Ultimately, investing in precise temperature control is an investment in the quality and integrity of your work.

Summary Table:

| Aspect | Importance |

|---|---|

| Stability | Maintains setpoint over time for reliable experiments |

| Uniformity | Prevents hot/cold spots for consistent material properties |

| Material Integrity | Avoids defects like porosity and ensures desired composition |

| Repeatability | Enables valid scientific conclusions and process consistency |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Split Tube, Muffle, and Vacuum Furnaces, along with CVD/PECVD Systems. Our strong deep customization capability ensures precise temperature control to meet your unique experimental needs—boosting reliability, repeatability, and efficiency. Contact us today to discuss how we can enhance your material processing and achieve superior results!

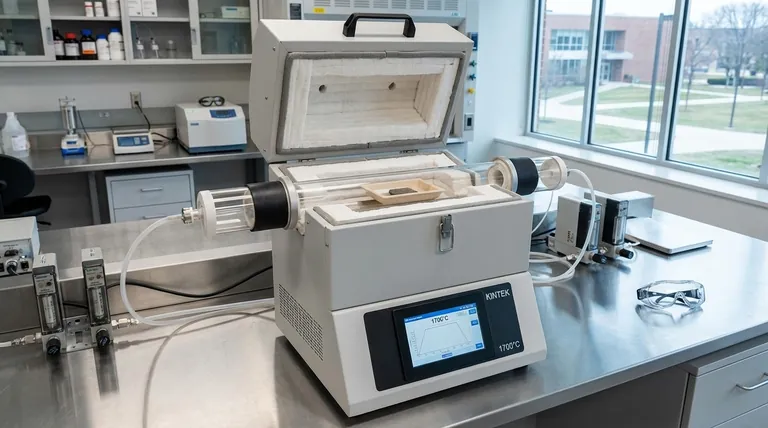

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability