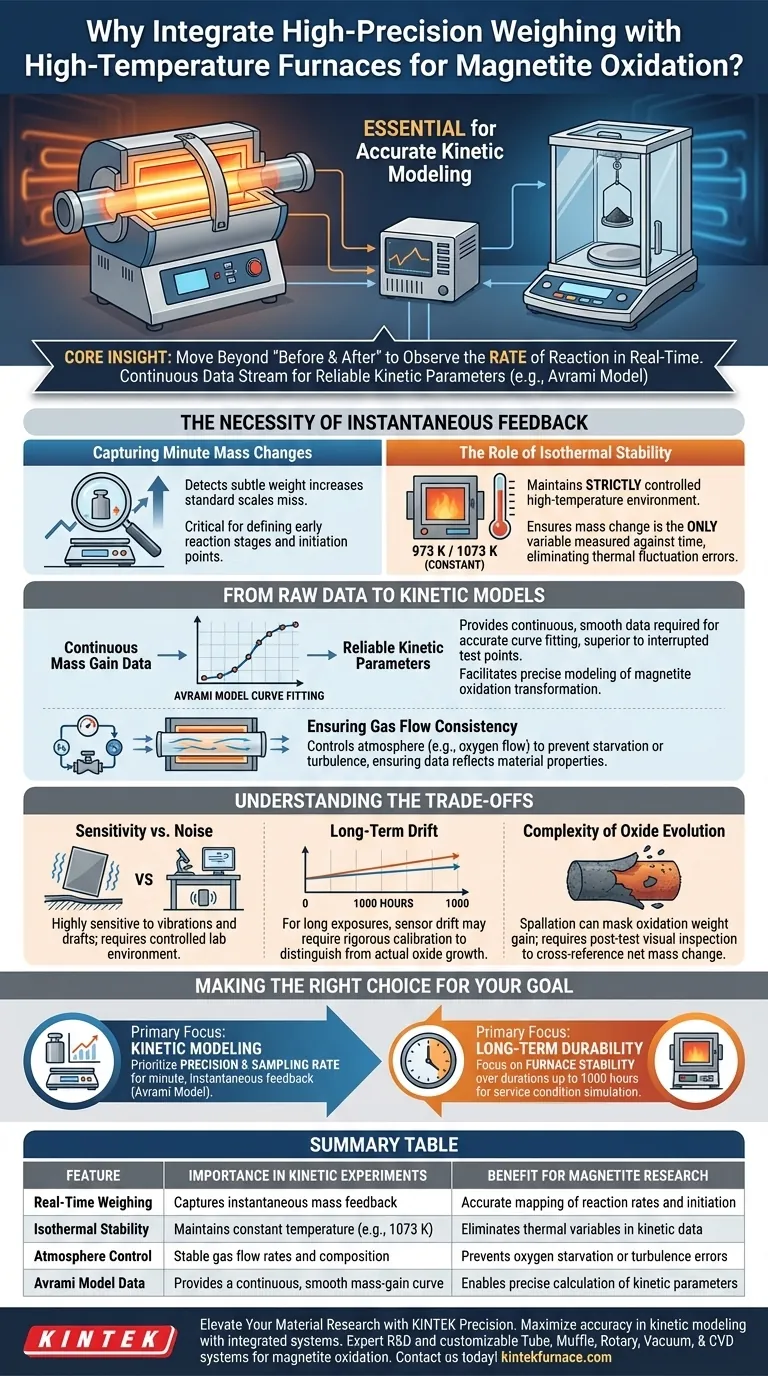

Integrating a high-precision weighing system with a high-temperature tube furnace is the only reliable method to capture the instantaneous mass feedback required for accurate kinetic modeling. This setup allows researchers to monitor minute weight increases in real-time while maintaining a strictly controlled isothermal environment, ensuring that the resulting data is precise enough to feed complex mathematical models.

Core Insight By coupling thermal stability with sensitive mass measurement, you move beyond simple "before and after" testing to observe the rate of reaction as it occurs. This continuous stream of data is the prerequisite for calculating reliable parameters for kinetic frameworks, such as the Avrami model.

The Necessity of Instantaneous Feedback

Capturing Minute Mass Changes

Magnetite oxidation is often a subtle process, particularly at the onset of the reaction. A high-precision weighing system detects minute weight increases that standard scales would miss.

This sensitivity is non-negotiable when trying to establish the exact reaction initiation point. Without this granularity, your data will lack the resolution needed to define the early stages of the oxidation curve.

The Role of Isothermal Stability

The tube furnace component provides the necessary stable high-temperature environment. For valid kinetic data, the temperature must remain constant (e.g., at specific set points like 973 K or 1073 K) throughout the experiment.

If the temperature fluctuates, the reaction rate changes, introducing variables that corrupt the mass change data. The integration of the furnace ensures that mass change is the only variable being measured against time.

From Raw Data to Kinetic Models

Validating the Avrami Model

The primary output of this integrated system is a dataset suitable for the Avrami model. This mathematical model describes how solids transform—in this case, how magnetite oxidizes over time.

To extract reliable parameters for this model, you need a continuous, smooth curve of mass gain. Discrete data points taken from interrupted tests are often insufficient for accurate curve fitting.

Ensuring Gas Flow Consistency

As noted in broader oxidation studies, maintaining stable gas flow rates and compositions is critical. The tube furnace facilitates this by controlling the atmosphere surrounding the sample.

This prevents oxygen starvation or turbulent flow from altering the oxidation rate, ensuring the kinetic data reflects the material's properties rather than environmental inconsistencies.

Understanding the Trade-offs

Sensitivity vs. Environmental Noise

High-precision weighing systems are incredibly sensitive to external vibrations and drafts. While they provide excellent data, they require a highly controlled laboratory environment to prevent noise from overshadowing the minute mass changes of the sample.

Long-Term Drift

For experiments requiring long-term exposure (up to 1000 hours), signal drift in the weighing mechanism can become a factor.

While these systems are excellent for capturing short-term kinetic rates, distinguishing between actual oxide growth and sensor drift over hundreds of hours requires rigorous calibration.

Complexity of Oxide Evolution

In long-duration tests, phenomena such as oxide scale spallation (flaking off) or the formation of non-protective layers can occur.

A weighing system measures net mass change; if spallation occurs simultaneously with oxidation, the data can be misinterpreted. You must cross-reference mass data with post-test visual inspection to understand if weight loss (spallation) is masking weight gain (oxidation).

Making the Right Choice for Your Goal

To select the correct experimental setup, you must define the specific aspect of oxidation you are investigating.

- If your primary focus is Kinetic Modeling: Prioritize the precision and sampling rate of the weighing system to ensure you capture the minute, instantaneous feedback required for the Avrami model.

- If your primary focus is Long-Term Durability: Focus on the furnace's stability over durations up to 1000 hours to realistically simulate service conditions and phenomena like chromium depletion or spallation.

The combination of precise mass tracking and thermal control transforms oxidation testing from a rough estimation into an exact science.

Summary Table:

| Feature | Importance in Kinetic Experiments | Benefit for Magnetite Research |

|---|---|---|

| Real-Time Weighing | Captures instantaneous mass feedback | Accurate mapping of reaction rates and initiation |

| Isothermal Stability | Maintains constant temperature (e.g., 1073 K) | Eliminates thermal variables in kinetic data |

| Atmosphere Control | Stable gas flow rates and composition | Prevents oxygen starvation or turbulence errors |

| Avrami Model Data | Provides a continuous, smooth mass-gain curve | Enables precise calculation of kinetic parameters |

Elevate Your Material Research with KINTEK Precision

Maximize the accuracy of your kinetic modeling with integrated thermal and mass measurement systems. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of magnetite oxidation and high-temperature research.

Ready to achieve superior data resolution for your lab? Contact us today to discuss your unique project needs!

Visual Guide

References

- A. Laarich, Kurt N. Wiegel. Effect of Particle Size on Magnetite Oxidation Behavior: A Modeling Approach Incorporating Ultra-Fine Particle Effects. DOI: 10.1007/s11663-025-03640-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is a lab tube furnace? The Ultimate Guide to Precision High-Temp Processing

- How do the nitrogen atmosphere and temperature control in a tube furnace affect carbonized lignin fiber quality?

- How does a dual-zone tube furnace control CoTeO4 crystal growth? Precision CVT Thermal Gradient Methods

- What is a split tube furnace? Unlock Easy Access for Complex Lab Experiments

- What is the role of a horizontal tube furnace in the plastic waste pyrolysis process? Driving Polymer Decomposition

- What role does a tube furnace play in the hydrogenation process of Ti6Al4V alloys? Master Hydrogen Diffusion Control

- How does an electric heating tube furnace ensure stable experimental conditions? Master Bio-Oil Upgrading Stability

- How does a tube furnace contribute to the carbonization of biomass? Master Precise Pyrolysis for Superior Materials