At its core, a split tube furnace is a high-temperature laboratory furnace whose cylindrical heating chamber is divided in half lengthwise. The two halves are connected by a hinge, allowing the furnace to be opened and closed. This simple yet critical design feature provides direct, unobstructed access to the interior work tube and the sample within.

The defining advantage of a split tube furnace is not just how it heats, but how it opens. This design prioritizes accessibility, making it the superior choice for experiments involving complex setups, frequent sample changes, or processes where the sample cannot be easily slid into a fixed tube.

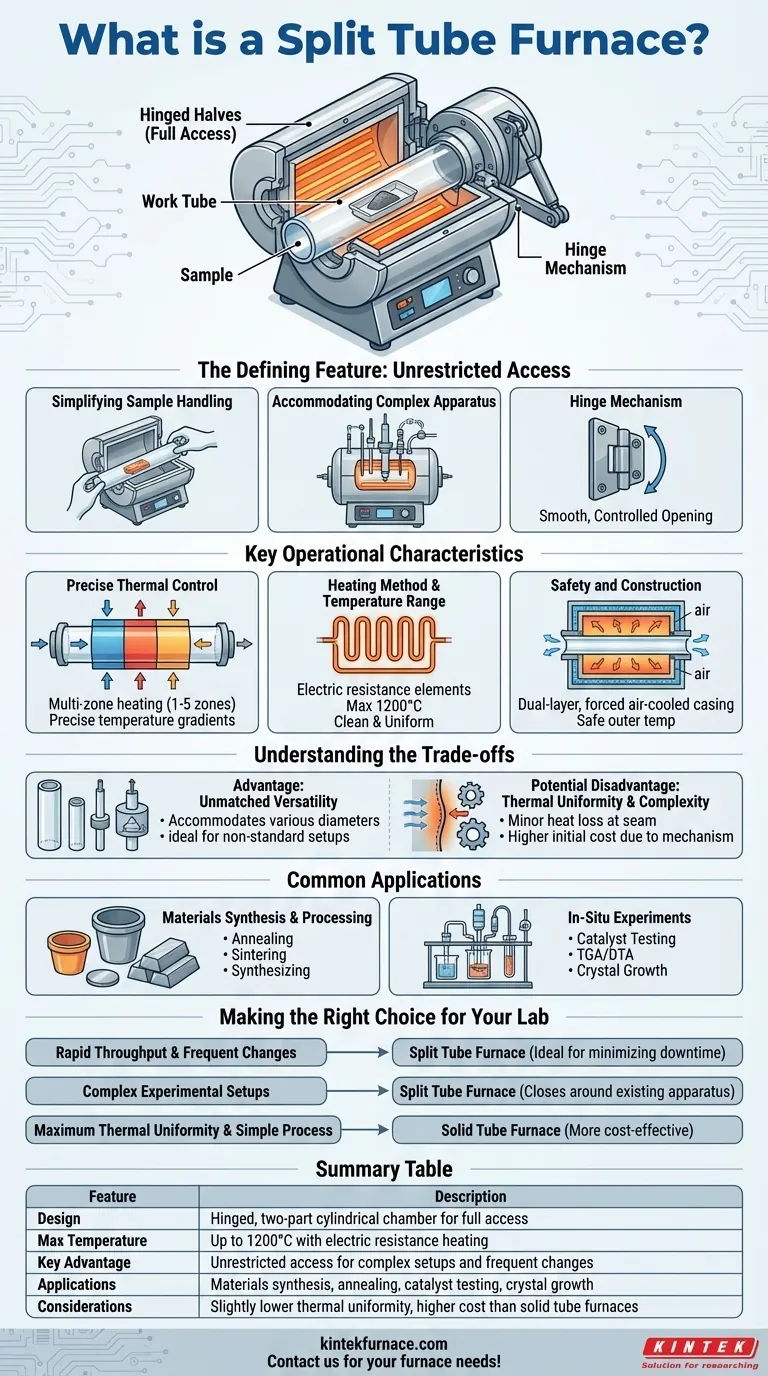

The Defining Feature: Unrestricted Access

The primary value of a split tube furnace comes directly from its hinged, two-part construction. This separates it fundamentally from standard solid tube furnaces.

The Hinge Mechanism

The furnace body is literally split into two semi-cylindrical halves. These are joined on one side by a robust hinge, sometimes equipped with pneumatic struts to ensure smooth, controlled opening and closing. This allows an operator to open the furnace completely.

Simplifying Sample Handling

In a traditional solid tube furnace, the work tube and sample must be carefully slid in and out from one end. A split tube furnace eliminates this. You can simply open the furnace, place the work tube and sample, and close the furnace around it. This is faster, safer, and reduces the risk of disturbing the sample.

Accommodating Complex Apparatus

This is where the split tube design excels. For experiments requiring multiple thermocouples, gas inlets, or other probes, the entire apparatus can be set up within the work tube first. The furnace is then closed around the fully assembled experiment, a task that would be impossible with a solid tube design.

Key Operational Characteristics

While its opening mechanism is the main feature, a split tube furnace shares many operational principles with other high-performance lab furnaces.

Precise Thermal Control

Many models offer multi-zone heating capabilities, with options for one, two, three, or even five independently controlled heated zones. This allows for the creation of precise temperature gradients along the length of the tube, which is critical for applications like chemical vapor deposition and crystal growth.

Heating Method and Temperature Range

These furnaces almost always use electric resistance heating elements, typically high-quality heating coils. This method provides clean, controllable, and uniform heat. Most standard models can achieve a maximum temperature of 1200°C.

Safety and Construction

Modern split tube furnaces are built with a dual-layer, forced air-cooled casing. This design actively removes heat from the exterior surface, ensuring the outside of the furnace remains at a safe temperature for operators even when the interior is at maximum heat.

Understanding the Trade-offs

Choosing a split tube furnace involves weighing its unique advantages against potential considerations. No single piece of equipment is perfect for every task.

Advantage: Unmatched Versatility

The ability to open the chamber makes the furnace incredibly versatile. It can accommodate a wide range of work tube diameters and is the go-to solution for any non-standard or evolving experimental setup.

Potential Disadvantage: Thermal Uniformity

The seam where the two halves of the furnace meet can be a potential source of minor heat loss compared to a seamless solid tube. While advanced insulation and design minimize this, a solid tube furnace may offer marginally better thermal uniformity for highly sensitive, static applications.

Potential Disadvantage: Mechanical Complexity

A hinged body with locking mechanisms is inherently more complex to manufacture than a simple, solid cylinder. This can translate to a higher initial cost compared to a solid tube furnace with similar heating specifications.

Common Applications

The unique design of the split tube furnace makes it ideal for specific scientific and industrial processes.

Materials Synthesis and Processing

The ease of loading and unloading makes it perfect for routine processes like annealing metals, sintering ceramics, and synthesizing inorganic compounds. These often involve processing many samples in sequence.

In-Situ Experiments

The ability to enclose a complex apparatus makes it essential for dynamic experiments. This includes catalyst testing, thermal analysis (TGA/DTA), and crystal growth, where probes and sensors must be positioned precisely within the reaction zone.

Making the Right Choice for Your Lab

Your choice between a split tube and a solid tube furnace should be driven by the nature of your work.

- If your primary focus is rapid throughput and frequent sample changes: The split tube design is ideal for minimizing downtime and simplifying the process.

- If your primary focus is accommodating complex experimental setups with multiple probes or connections: The split tube furnace's ability to close around an existing apparatus is its single most powerful advantage.

- If your primary focus is maximum thermal uniformity for a simple, fixed process: A traditional solid tube furnace might be a more straightforward and cost-effective choice.

Ultimately, understanding this core design principle empowers you to select the right tool not just for the material you're heating, but for the complexity of the entire experiment.

Summary Table:

| Feature | Description |

|---|---|

| Design | Hinged, two-part cylindrical chamber for full access |

| Max Temperature | Up to 1200°C with electric resistance heating |

| Key Advantage | Unrestricted access for complex setups and frequent changes |

| Applications | Materials synthesis, annealing, catalyst testing, crystal growth |

| Considerations | Slightly lower thermal uniformity, higher cost than solid tube furnaces |

Ready to enhance your lab's efficiency with a split tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're handling complex apparatus or frequent sample changes, we can help you achieve superior results. Contact us today to discuss how our furnaces can benefit your research and processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety