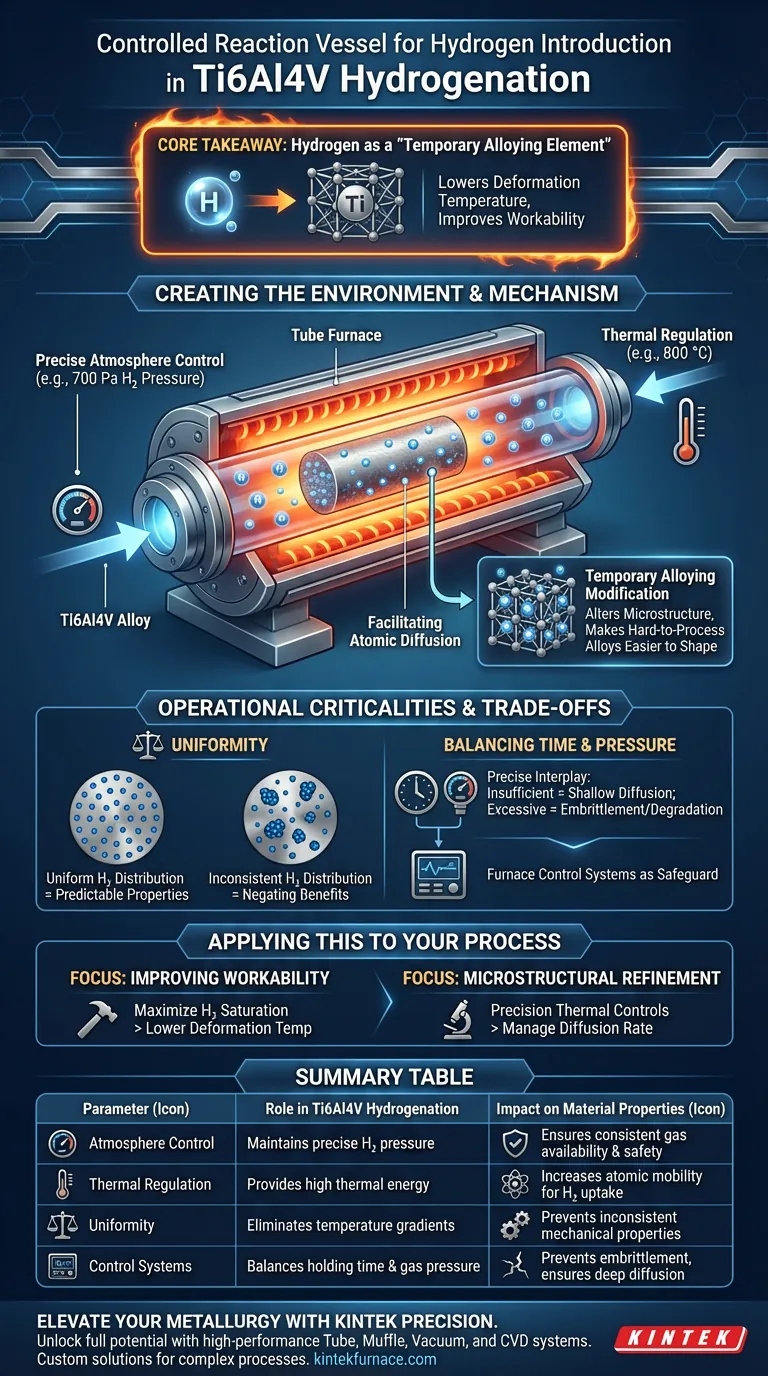

The tube furnace serves as a controlled reaction vessel that establishes the specific thermodynamic conditions necessary to introduce hydrogen into Ti6Al4V alloys. It functions by isolating the alloy in a high-temperature environment while maintaining a precise hydrogen atmosphere, enabling the gas to penetrate the metal's structure.

Core Takeaway The tube furnace allows for the use of hydrogen as a "temporary alloying element." By strictly controlling heat and pressure, the furnace facilitates hydrogen diffusion into the titanium lattice, which significantly lowers the material's deformation temperature and improves its workability.

Creating the Necessary Environment

Precise Atmosphere Control

The primary role of the tube furnace is to generate and maintain a controllable hydrogen atmosphere. Unlike standard heat treatment, hydrogenation requires a specific chemical environment.

The furnace must maintain a regulated hydrogen pressure—often a low overpressure such as 700 Pa—to ensure the gas is available for absorption without compromising safety or process stability.

Thermal Regulation

Hydrogen diffusion is a thermally activated process. The tube furnace provides the high thermal energy required to expand the metal lattice and increase atomic mobility.

Operators can set exact heating rates and holding times (e.g., 800 °C for 1 hour) to ensure the material reaches the optimal state for hydrogen uptake.

The Mechanism of Hydrogenation

Facilitating Atomic Diffusion

Inside the furnace, the combination of heat and pressure drives hydrogen atoms into the titanium alloy matrix.

The furnace ensures this diffusion is uniform across the material. This uniformity is critical for consistent modification of the alloy's properties throughout its cross-section.

Temporary Alloying Modification

The ultimate goal of using the tube furnace is to leverage hydrogen as a temporary alloying element.

By successfully diffusing hydrogen into the lattice, the furnace treatment alters the alloy's microstructure. This lowers the energy required to deform the material, making hard-to-process alloys like Ti6Al4V easier to shape and manipulate.

Operational Criticalities and Trade-offs

The Necessity of Uniformity

The tube furnace must deliver exceptionally uniform heating. If the temperature gradient varies along the tube, the concentration of hydrogen within the alloy will be inconsistent.

Inconsistent hydrogen distribution leads to unpredictable mechanical properties, negating the benefits of the treatment.

Balancing Time and Pressure

Success relies on the precise interplay between the holding time and hydrogen pressure.

Insufficient time or pressure results in shallow diffusion, while excessive exposure can lead to material embrittlement or microstructure degradation. The furnace's control systems are the safeguard against these extremes.

Applying This to Your Process

If your primary focus is improving workability: Ensure the furnace creates a stable environment that maximizes hydrogen saturation to sufficiently lower the deformation temperature.

If your primary focus is microstructural refinement: Prioritize the precision of the furnace's thermal controls to manage the rate of diffusion and ensure a uniform lattice modification.

The tube furnace is not just a heat source; it is the precision tool that turns hydrogen into a functional processing aid.

Summary Table:

| Parameter | Role in Ti6Al4V Hydrogenation | Impact on Material Properties |

|---|---|---|

| Atmosphere Control | Maintains precise hydrogen pressure (e.g., 700 Pa) | Ensures consistent gas availability and safety |

| Thermal Regulation | Provides high thermal energy (e.g., 800 °C) | Increases atomic mobility for hydrogen uptake |

| Uniformity | Eliminates temperature gradients along the tube | Prevents inconsistent mechanical properties |

| Control Systems | Balances holding time and gas pressure | Prevents embrittlement and ensures deep diffusion |

Elevate Your Metallurgy with KINTEK Precision

Unlock the full potential of your Ti6Al4V alloys using hydrogen as a temporary alloying element. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Vacuum, and CVD systems tailored for complex hydrogenation and heat treatment processes. Whether you need to refine microstructures or lower deformation temperatures, our customizable lab high-temp furnaces provide the thermal uniformity and atmosphere control your research demands.

Ready to optimize your alloying process? Contact KINTEK experts today to find the perfect thermal solution for your unique needs.

Visual Guide

References

- Jianhua Sun, Zhonggang Sun. Ti6Al4V-0.72H on the Establishment of Flow Behavior and the Analysis of Hot Processing Maps. DOI: 10.3390/cryst14040345

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- Why is a high-temperature tube furnace used for the in-situ reduction of NiO/Al2O3 catalysts? Optimize Your Lab Results

- Why is an atmosphere-controlled tube furnace required for NC substrate preparation? Essential for carbonization.

- What is the primary function of a Tube Furnace in converting PET to activated carbon? Achieve Precision Carbonization

- What role does a horizontal tubular furnace play in VACNT synthesis? Master CVD Growth for High-Quality Nanotubes

- Why is sulfurization treatment in a quartz tube furnace required after CZTS thin film deposition? Expert Guide

- How does a tube furnace contribute to the carbonization of biomass? Master Precise Pyrolysis for Superior Materials

- What synthesis environment does a vacuum tube furnace provide for C@TiC nanoparticles? Master Oxygen-Free Pyrolysis