Sulfurization acts as the critical "activation" step that transforms a raw, deposited precursor into a functional photovoltaic material. The treatment is required to compensate for elemental sulfur lost during the initial deposition and to drive the thermodynamic phase transition from a disordered, amorphous state into a highly crystalline kesterite structure.

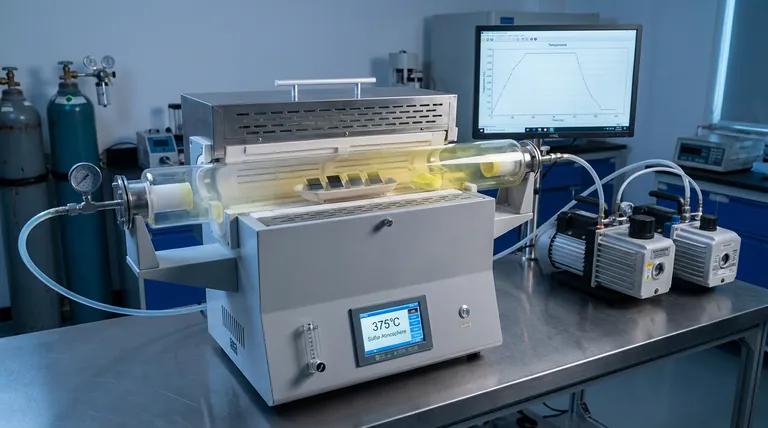

The Core Insight "As-deposited" CZTS films rarely possess the necessary structural integrity or chemical balance to function effectively. Sulfurization in a quartz tube furnace corrects these deficiencies by restoring lost sulfur and providing the thermal energy required to reorganize atoms into the specific crystal lattice needed for maximum light absorption.

Restoring Chemical Stoichiometry

The primary challenge in creating Copper Zinc Tin Sulfide (CZTS) thin films is the volatility of sulfur.

Compensating for Sulfur Loss

During the initial deposition process, high energy or vacuum conditions often cause sulfur atoms to escape the film. This leaves the material sulfur-deficient, which ruins its electronic properties.

The Role of Sulfur Vapor

The quartz tube furnace solves this by creating a sulfur-rich atmosphere. By heating sulfur powder alongside the film, the furnace generates high-pressure sulfur vapor. This vapor forces sulfur atoms back into the film, filling the vacancies created during deposition and restoring the correct chemical ratio (stoichiometry).

Achieving the Kesterite Phase

Chemical balance alone is not enough; the atoms must also be arranged in a specific geometric pattern to convert light into electricity.

Moving from Amorphous to Crystalline

Immediately after deposition, the CZTS film typically exists in an amorphous (disordered) state or as a mixture of various unwanted phases. It lacks a defined crystal structure.

The Thermal Transformation

The furnace provides a controlled high-temperature environment—typically around 375 °C—which supplies the thermal energy necessary for atomic rearrangement. This heat drives a phase transformation, converting the disordered material into a unified, polycrystalline structure.

Target Structure: Kesterite

The ultimate goal of this heating process is to achieve the kesterite crystal structure. This specific arrangement of atoms significantly enhances the material's ability to absorb light and transport electrons, turning an inert film into a viable semiconductor.

Understanding the Trade-offs

While sulfurization is essential, it introduces specific processing risks that must be managed to ensure film quality.

Temperature Sensitivity

Precision is paramount. If the furnace temperature is too low, the phase transformation will be incomplete, leaving the film with poor crystallinity. Conversely, excessive heat can lead to the decomposition of the CZTS film or the evaporation of other volatile elements like Tin (Sn).

Secondary Phase Formation

The sulfur atmosphere must be carefully controlled. An imbalance in sulfur vapor pressure can lead to the formation of secondary phases (impurities) on the surface or grain boundaries. These impurities can act as recombination centers, reducing the overall efficiency of the solar cell.

Making the Right Choice for Your Goal

The parameters of your sulfurization treatment should be adjusted based on the specific deficiencies of your as-deposited film.

- If your primary focus is improving Light Absorption: Prioritize reaching the optimal crystallization temperature (e.g., 375 °C) to ensure the formation of large, high-quality kesterite grains.

- If your primary focus is Compositional Accuracy: Focus on the quantity of sulfur powder and the pressure within the tube to strictly compensate for the specific rate of sulfur loss observed during your deposition method.

Ultimately, the sulfurization furnace acts as a corrective tool, refining the raw ingredients of your film into a high-performance device.

Summary Table:

| Process Aspect | Role of Sulfurization | Impact on CZTS Performance |

|---|---|---|

| Chemical Balance | Compensates for sulfur loss | Restores stoichiometry & electronic properties |

| Crystallinity | Converts amorphous to polycrystalline | Enhances light absorption & electron transport |

| Phase Control | Facilitates Kesterite formation | Ensures functional semiconductor structure |

| Environment | Sulfur-rich atmosphere (375°C) | Prevents decomposition & atomic vacancies |

Elevate Your Semiconductor Research with KINTEK

Precision sulfurization is the key to high-performance CZTS thin films. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory requirements.

Whether you need precise temperature control to achieve the kesterite phase or a specialized atmosphere for chemical stoichiometry, our lab high-temp furnaces provide the reliability your research demands.

Ready to optimize your thin film deposition process? Contact our technical experts today to find the perfect furnace solution for your application.

References

- Serap Yi̇ği̇t Gezgi̇n, Hamdi Şükür Kılıç. Microstrain effects of laser-ablated Au nanoparticles in enhancing CZTS-based 1 Sun photodetector devices. DOI: 10.1039/d4cp00238e

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What role does a high-purity quartz tube furnace play in graphene growth? Achieve Conformal Optical Resonator Coating

- What are some common applications of vertical tube furnaces? Unlock Precision in High-Temp Processes

- What is the critical role of a programmable temperature tube reduction furnace? Achieve Precision Catalyst Activation

- How does a tube furnace improve the crystal structure of zinc oxide thin films? Achieve High-Performance Crystallinity

- How does a vertical tube furnace ensure effective hydrogen reduction reactions? Optimize Rare Earth Tailing Processing

- What are the advantages of combining an online mass spectrometer with a fixed-bed reactor? Boost Kinetic Precision

- What advanced materials research applications involve tube furnaces? Unlock Precision for Next-Gen Materials

- What is the critical role of a tube furnace in the preparation of beta-PbO powder? Optimize Lead-Acid Battery Recycling