In advanced materials research, tube furnaces are the workhorses for synthesizing and processing a vast range of next-generation materials. They are indispensable for fabricating thin films using chemical vapor deposition (CVD), creating nanomaterials like graphene and carbon nanotubes, developing energy components like solid oxide fuel cells, and improving the properties of high-performance ceramics and alloys through heat treatment.

A tube furnace's true value in advanced research is not just its ability to reach high temperatures, but its capacity to create a highly controlled and isolated environment. This precise control over temperature, atmosphere, and pressure is the fundamental requirement for synthesizing and processing the materials that define modern technology.

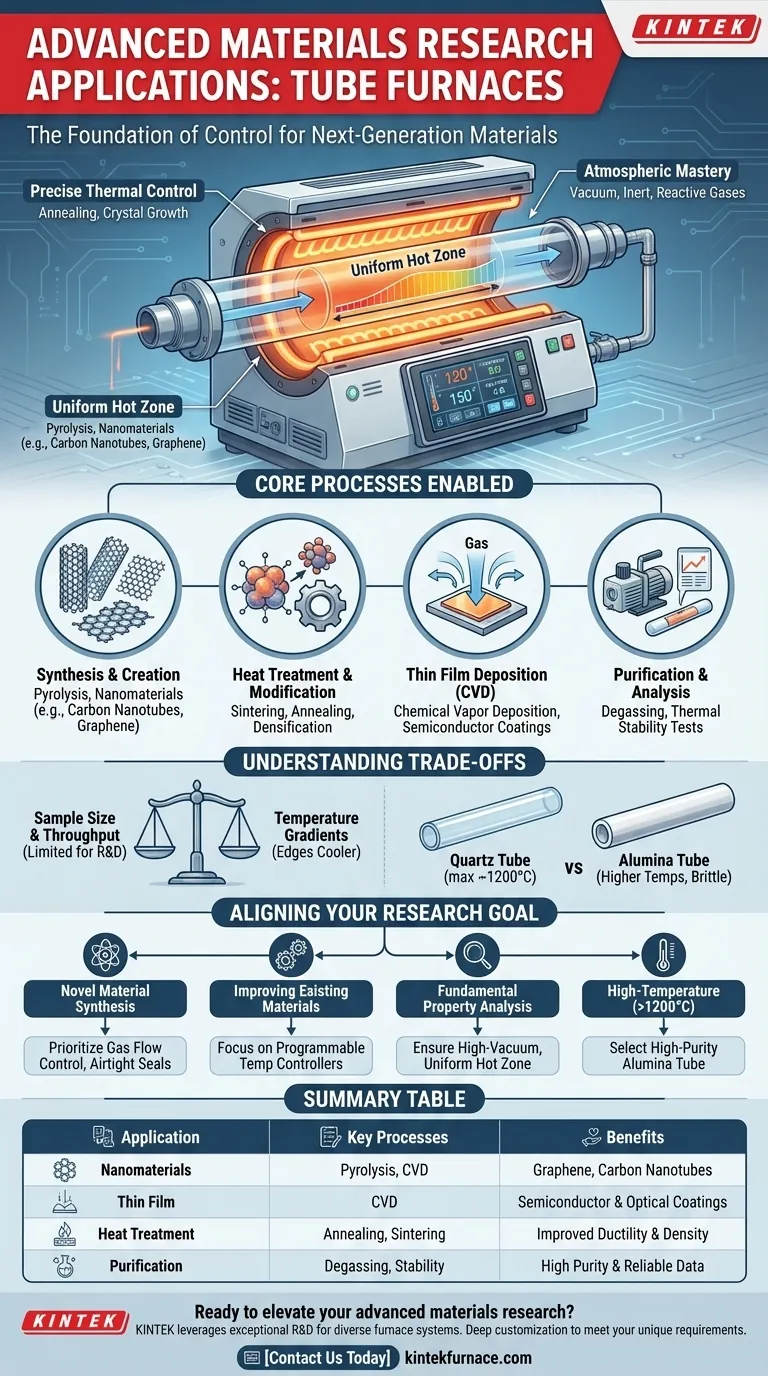

The Foundation of Control: Thermal and Atmospheric Precision

The power of a tube furnace comes from its ability to isolate a sample from the outside world and subject it to extremely specific conditions. This control is the key to creating materials with novel and repeatable properties.

Achieving Precise Thermal Uniformity

Repeatable materials science requires a stable and uniform temperature. A tube furnace is designed to create a "hot zone" in its center where the temperature variation is minimal.

This uniformity is critical for processes like annealing, where it ensures a material's entire crystal structure is modified evenly, or for crystal growth, where stable temperatures prevent the formation of defects.

Mastering the Atmosphere

Many advanced materials are highly sensitive to oxygen and other atmospheric gases, especially at high temperatures. A tube furnace's sealed chamber allows researchers to dictate the exact gaseous environment.

This includes creating a vacuum to remove contaminants, introducing an inert gas (like argon) to prevent unwanted oxidation, or flowing specific reactive gases to drive chemical reactions on a material's surface.

Core Processes Enabled by Tube Furnaces

This precise environmental control allows researchers to execute a wide variety of fundamental material processing techniques.

Synthesis and Material Creation

Tube furnaces are at the forefront of creating entirely new materials. Pyrolysis, the thermal decomposition of a material in an oxygen-free environment, is used to produce everything from carbon fibers to hydrogen.

This is also the primary method for creating many nanomaterials, including carbon nanotubes and graphene, which are grown under specific temperatures and gas flows.

Heat Treatment and Material Modification

Heat treatment is used to alter a material's microstructure and, by extension, its physical properties.

Processes like sintering use heat to fuse powders into a solid, dense object, which is essential for manufacturing advanced ceramics and precision metal parts. Annealing is used to reduce hardness, increase ductility, and relieve internal stresses in metals and glass.

Thin Film Deposition and Coating

Chemical Vapor Deposition (CVD) is a cornerstone technique in semiconductor and nanotechnology manufacturing, and it relies entirely on the capabilities of a tube furnace.

In CVD, precursor gases are flowed through the hot tube, where they react and deposit as a solid, ultra-thin film onto a substrate. This is how many electronic components, protective coatings, and optical films are made.

Purification and Analysis

The controlled environment is also perfect for purifying materials and analyzing their behavior. Degassing in a vacuum removes trapped gases from a material, which is critical for high-purity metals and components used in vacuum systems.

Researchers also use tube furnaces to conduct thermal stability tests, observing how a material changes or breaks down as it is heated, providing crucial data for aerospace and energy applications.

Understanding the Trade-offs and Limitations

While incredibly versatile, a tube furnace is not the right tool for every job. Understanding its limitations is key to successful research.

Sample Size and Throughput

Tube furnaces are optimized for research, development, and small-batch production. The diameter of the process tube inherently limits the size of the sample, making them generally unsuitable for high-volume manufacturing.

Temperature Gradients

While the central hot zone is highly uniform, the temperature naturally drops off toward the cooler ends of the tube. This can be a limitation if a very large, uniform zone is needed, though it can also be leveraged for experiments that study material behavior across a temperature gradient.

Material Compatibility

The process tube itself can be a limiting factor. Quartz tubes are common but are limited to temperatures around 1200°C and can be attacked by certain reactive materials. Alumina tubes can reach much higher temperatures but may be more brittle. The choice of tube material must be compatible with the process temperature and chemistry.

Aligning the Furnace with Your Research Goal

To select or use a tube furnace effectively, you must match its capabilities to your primary objective.

- If your primary focus is novel material synthesis (e.g., nanotubes, 2D materials): Prioritize a system with excellent gas flow control and airtight seals for running CVD and pyrolysis reactions.

- If your primary focus is improving existing materials (e.g., ceramics, metals): Focus on a furnace with programmable temperature controllers for precise, repeatable thermal cycles for sintering and annealing.

- If your primary focus is fundamental property analysis (e.g., thermal stability): Ensure you have high-vacuum capabilities and a uniform hot zone to get clean, accurate, and uncontaminated measurement data.

- If your primary focus is high-temperature applications (>1200°C): You will need a furnace equipped with a high-purity alumina tube and appropriate high-temperature heating elements.

Ultimately, the tube furnace serves as a controlled micro-environment, making it an indispensable tool for discovering and perfecting the materials of the future.

Summary Table:

| Application | Key Processes | Benefits |

|---|---|---|

| Nanomaterials Synthesis | Pyrolysis, CVD | Creates graphene, carbon nanotubes with controlled gas flow |

| Thin Film Deposition | Chemical Vapor Deposition (CVD) | Enables semiconductor and optical coatings |

| Heat Treatment | Annealing, Sintering | Improves material properties like ductility and density |

| Purification & Analysis | Degassing, Thermal Stability Tests | Ensures high purity and reliable data for aerospace/energy |

Ready to elevate your advanced materials research with tailored high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced furnace systems, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether for nanomaterials synthesis, heat treatment, or thin film deposition. Contact us today to discuss how our solutions can enhance your research efficiency and outcomes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety