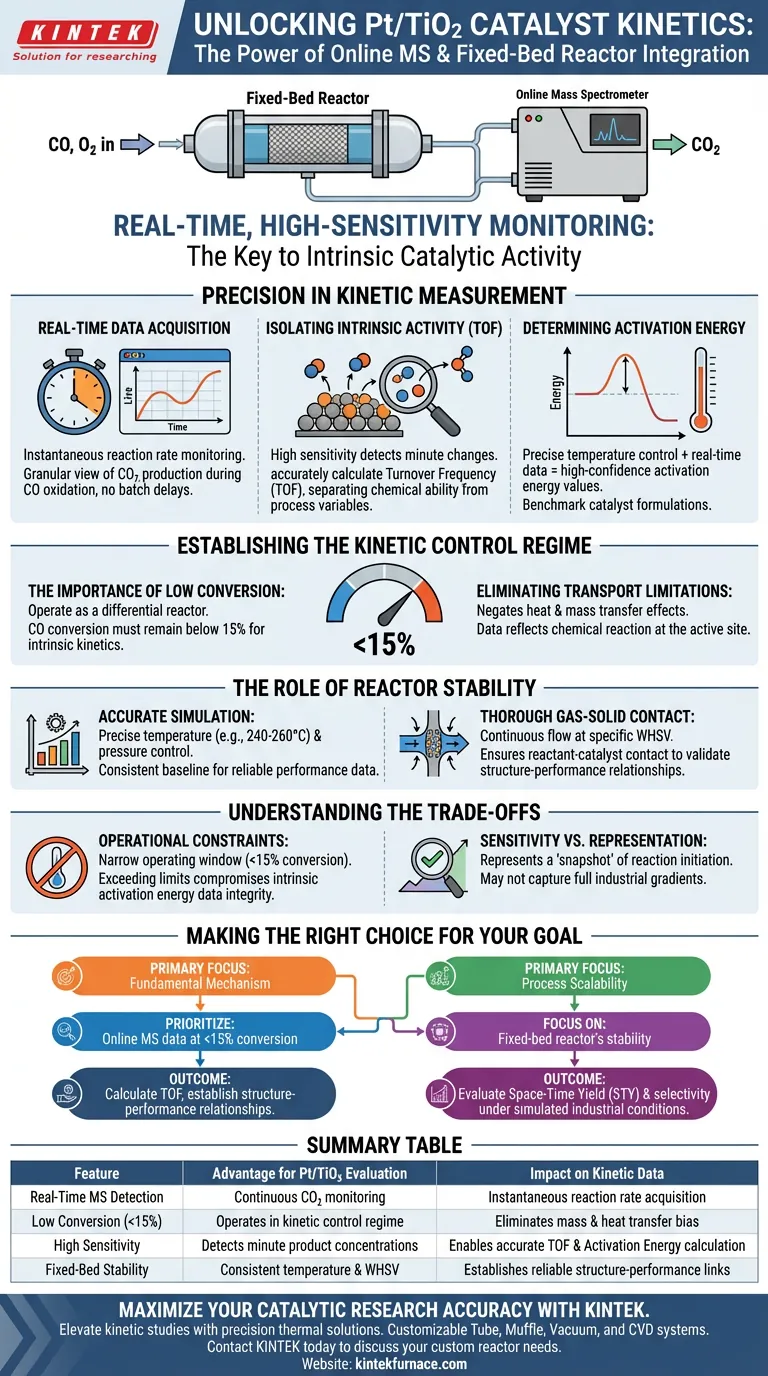

Combining an online mass spectrometer (MS) with a fixed-bed reactor provides the critical capability of real-time, high-sensitivity monitoring of product formation, such as carbon dioxide (CO2) during oxidation reactions. This integration allows you to precisely calculate intrinsic catalytic activity—measured as Turnover Frequency (TOF)—and apparent activation energy, which are essential for determining the fundamental performance of Pt/TiO2 catalysts.

By isolating intrinsic kinetics from external variables, this setup enables you to establish accurate structure-performance relationships, linking specific platinum coordination environments directly to catalytic output.

Precision in Kinetic Measurement

Real-Time Data Acquisition

The primary advantage of adding an online MS to your flow system is the ability to monitor reaction rates instantaneously.

Rather than waiting for batch analysis, the MS detects the production rate of CO2 continuously during the Carbon Monoxide (CO) oxidation process. This provides a granular view of how the catalyst responds to changes in conditions moment-by-moment.

Isolating Intrinsic Activity (TOF)

To understand the true efficiency of a catalyst, you must measure its Turnover Frequency (TOF).

The high sensitivity of the online MS allows for the detection of minute changes in product concentration. This precision is required to calculate the TOF accurately, separating the catalyst's inherent chemical ability from broader process variables.

Determining Activation Energy

Accurate kinetic modeling requires a precise value for apparent activation energy.

By combining precise temperature control from the reactor with real-time rate data from the MS, you can derive activation energy values with high confidence. This metric serves as a benchmark for comparing different catalyst formulations.

Establishing the Kinetic Control Regime

The Importance of Low Conversion

To measure intrinsic kinetics, you must operate under a kinetic control regime.

The primary reference dictates that CO conversion must remain below 15% during these evaluations. At this low conversion level, the reactor operates as a differential reactor, assuming the reaction rate is constant across the bed.

Eliminating Transport Limitations

The combination of this specific conversion limit and the fixed-bed setup helps negate heat and mass transfer effects.

This ensures that the data collected by the MS reflects the chemical reaction at the active site, rather than diffusion limitations within the reactor.

The Role of Reactor Stability

Accurate Simulation of Conditions

While the MS provides detection, the fixed-bed reactor ensures the environment is stable and reproducible.

As noted in supplementary contexts, these reactors maintain precise temperature control (e.g., 240-260°C) and pressure stability. This creates a consistent baseline, ensuring that fluctuations in MS data are due to catalyst performance, not environmental instability.

Thorough Gas-Solid Contact

The fixed-bed design facilitates continuous flow at a specific Weight Hourly Space Velocity (WHSV).

This ensures thorough contact between reactant gases and the catalyst bed. Consistent contact is necessary to validate the structure-performance relationships derived from the MS data.

Understanding the Trade-offs

Operational Constraints

To maintain the integrity of the kinetic data, you are restricted to a narrow operating window.

Specifically, you must maintain conversion rates below 15%. Exceeding this limit moves the system out of the kinetic control regime, making the resulting MS data less reliable for calculating intrinsic activation energy.

Sensitivity vs. Representation

While the setup provides deep insight into intrinsic kinetics, it essentially represents a "snapshot" of the reaction initiation.

It may not fully capture the complex gradients (concentration or thermal) that occur in an industrial reactor operating at full conversion capacity.

Making the Right Choice for Your Goal

When designing your evaluation protocol for Pt/TiO2 catalysts, use this setup to align with your specific objectives:

- If your primary focus is Fundamental Mechanism: Prioritize the online MS data at <15% conversion to calculate TOF and establish structure-performance relationships.

- If your primary focus is Process Scalability: Focus on the fixed-bed reactor's stability to evaluate Space-Time Yield (STY) and selectivity under simulated industrial conditions.

This integrated approach transforms raw reaction data into a definitive understanding of the catalyst's active sites.

Summary Table:

| Feature | Advantage for Pt/TiO2 Evaluation | Impact on Kinetic Data |

|---|---|---|

| Real-Time MS Detection | Continuous monitoring of CO2 production | Instantaneous reaction rate acquisition |

| Low Conversion (<15%) | Operates in kinetic control regime | Eliminates mass and heat transfer bias |

| High Sensitivity | Detects minute product concentrations | Enables accurate TOF and Activation Energy calculation |

| Fixed-Bed Stability | Consistent temperature and WHSV | Establishes reliable structure-performance links |

Maximize Your Catalytic Research Accuracy

Elevate your lab's kinetic studies with KINTEK’s precision-engineered thermal solutions. Backed by expert R&D and manufacturing, we offer high-performance Tube, Muffle, Vacuum, and CVD systems—all fully customizable to integrate seamlessly with your online mass spectrometry setups.

Whether you are determining Turnover Frequency or exploring fundamental mechanisms, our systems provide the thermal stability required for rigorous catalyst evaluation.

Contact KINTEK today to discuss your custom reactor needs

Visual Guide

References

- Wenjie Zang, Xiaoqing Pan. Distribution of Pt single atom coordination environments on anatase TiO2 supports controls reactivity. DOI: 10.1038/s41467-024-45367-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Ultra High Vacuum CF Flange Stainless Steel Sapphire Glass Observation Sight Window

People Also Ask

- How do tube furnaces contribute to transport reactions and crystal production? Master High-Purity Synthesis with Precision Control

- What are the technical advantages of using an oscillating tube furnace for tellurium dioxide recovery?

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the specifications for three-zone and three-phase horizontal tube furnace models? Find the Perfect Fit for Your Lab

- Why is high-purity nitrogen utilized as a carrier gas during the oil shale pyrolysis process? Ensure Precise Analysis

- What are the advantages of resistance heating tube furnaces? Achieve Precise, Cost-Effective Thermal Processing

- What role does a quartz tube furnace play in polyimide pyrolysis? Precision Control for Carbon Molecular Sieves

- What are the key advantages of using a rotary tube furnace? Achieve Dynamic, Uniform Heating for Powders