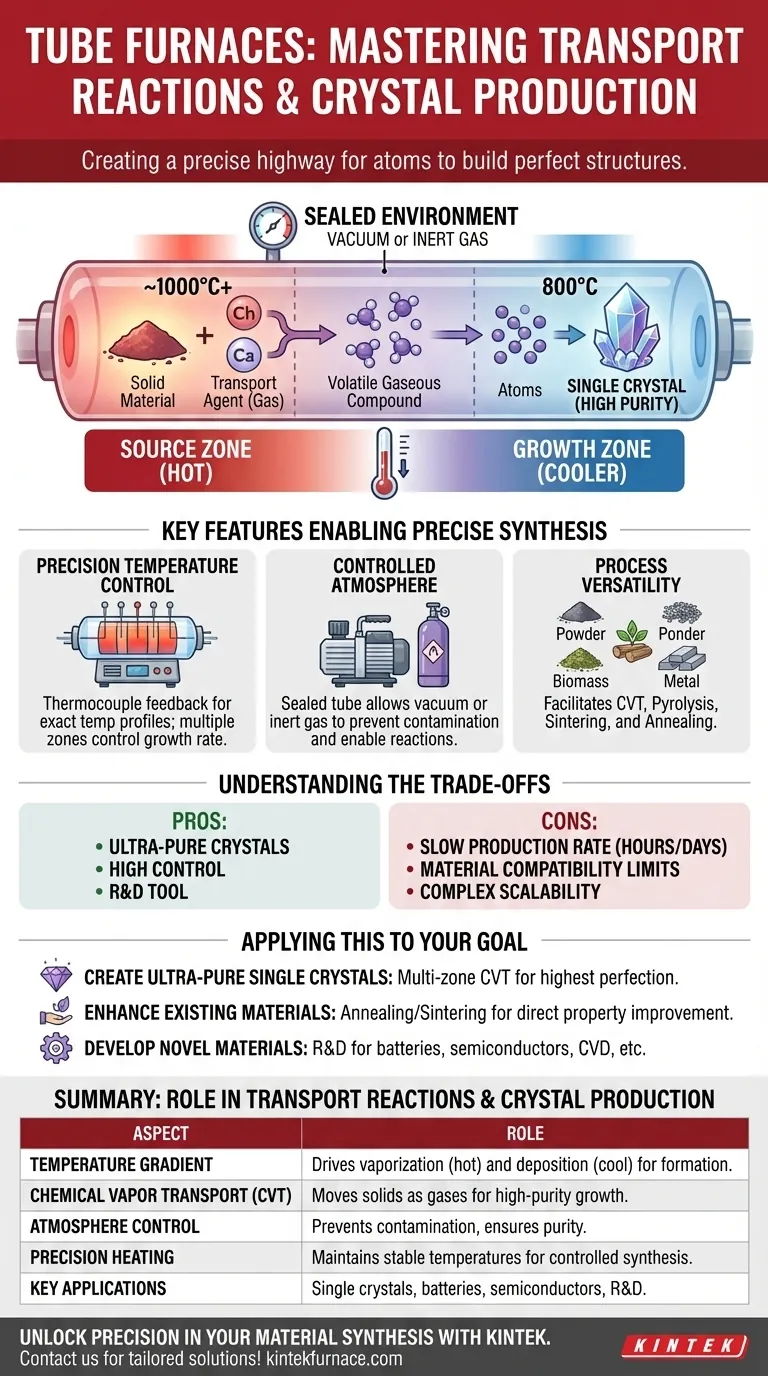

At its core, a tube furnace enables transport reactions and crystal production by creating a highly controlled temperature gradient within a sealed environment. This precise thermal landscape forces materials to vaporize in a hot zone, travel as a gas, and then deposit as a high-purity solid or crystal in a cooler zone, a process known as chemical vapor transport.

The true function of a tube furnace in advanced synthesis is not just heating, but creating a precisely controlled "highway" for atoms. By managing temperature zones and atmosphere, it allows scientists to deconstruct a material into a gas and meticulously rebuild it into a perfect crystal structure elsewhere.

The Core Principle: Chemical Vapor Transport

The primary mechanism a tube furnace uses for crystal growth is Chemical Vapor Transport (CVT). This process is fundamentally about moving a solid material from one location to another by temporarily converting it into a gas.

What is a Transport Reaction?

A solid material that is not easily vaporized on its own is placed in the furnace's sealed tube. It then reacts with a gaseous "transport agent" at high temperatures to form a new, volatile gaseous compound.

The Role of the Temperature Gradient

This is where the tube furnace excels. It establishes a stable temperature gradient, meaning one end of the tube (the "source zone") is hotter than the other (the "growth zone").

The initial reaction that forms the gaseous compound happens in the hot source zone. This gas then naturally diffuses or flows toward the cooler growth zone.

Deposition and Crystal Growth

In the cooler zone, the chemical reaction reverses. The gaseous compound becomes unstable at the lower temperature and decomposes, depositing the original solid material and releasing the transport agent gas.

Because this deposition happens slowly and under pristine conditions, the atoms arrange themselves into a highly ordered, low-energy state: a single crystal. The freed transport agent can then travel back to the hot zone to repeat the cycle.

Key Features Enabling Precise Synthesis

Several features of a tube furnace are critical for making these high-purity processes possible. The success of the reaction depends entirely on the degree of control the equipment provides.

Precision Temperature Control

Modern tube furnaces use thermocouple feedback systems to maintain exact temperatures, often within a single degree. Furnaces with multiple, independently controlled heating zones can create very specific and stable temperature profiles, which is essential for controlling the rate and quality of crystal growth.

Controlled Atmosphere

The sealed nature of the process tube is non-negotiable. It allows operators to either pull a vacuum to remove contaminants or introduce a specific inert or reactive gas. This controlled atmosphere is necessary to enable the desired transport reaction while preventing unwanted side reactions, like oxidation.

Process Versatility

While ideal for CVT, this setup also facilitates other critical material synthesis processes. Reactions like pyrolysis (thermal decomposition for biomass), sintering (forming a solid mass from powder below its melting point), and annealing (heat treatment to alter microstructure) all rely on the same principles of precise thermal and atmospheric control.

Understanding the Trade-offs

While powerful, the tube furnace and CVT method are not a universal solution. Understanding their limitations is key to using them effectively.

Rate of Production

Growing high-quality crystals via CVT is often an extremely slow process. It can take many hours, or even days, to produce just a few grams of material. This makes it ideal for research and development but challenging for mass production.

Material Compatibility

The CVT method is limited to materials that can form a volatile compound with a suitable transport agent at a reasonable temperature and pressure. Some materials may decompose or fail to react, making them incompatible with this technique.

Process Scalability

Tube furnaces are masters of the lab bench and small-batch pilot production. However, scaling these processes to an industrial level can be complex and expensive, often requiring entirely different reactor designs.

Applying This to Your Goal

Your choice of process depends entirely on the final material you hope to achieve.

- If your primary focus is creating ultra-pure single crystals: Chemical Vapor Transport within a multi-zone tube furnace is the definitive method for achieving the highest structural perfection.

- If your primary focus is enhancing the properties of existing metals or ceramics: Processes like annealing, hardening, or sintering in a single-zone furnace are more direct and efficient.

- If your primary focus is developing novel functional materials (for batteries or semiconductors): A tube furnace is an indispensable R&D tool for testing synthesis routes like graphitization, carbonization, and chemical vapor deposition.

Ultimately, the tube furnace provides an unparalleled level of control, making it a cornerstone for anyone manipulating materials at the atomic level.

Summary Table:

| Aspect | Role in Transport Reactions & Crystal Production |

|---|---|

| Temperature Gradient | Drives vaporization in hot zones and deposition in cooler zones for crystal formation. |

| Chemical Vapor Transport (CVT) | Moves solids as gases using transport agents, enabling high-purity crystal growth. |

| Atmosphere Control | Sealed environments with vacuum or gases prevent contamination and ensure reaction purity. |

| Precision Heating | Multi-zone furnaces maintain stable temperatures for controlled synthesis rates. |

| Key Applications | Single crystal production, material synthesis for batteries, semiconductors, and R&D. |

Unlock Precision in Your Material Synthesis with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements for transport reactions and crystal production. Whether you're developing novel functional materials or aiming for ultra-pure single crystals, our expertise ensures optimal performance and reliability.

Contact us today to discuss how our tailored solutions can accelerate your research and innovation—Get in touch now!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing