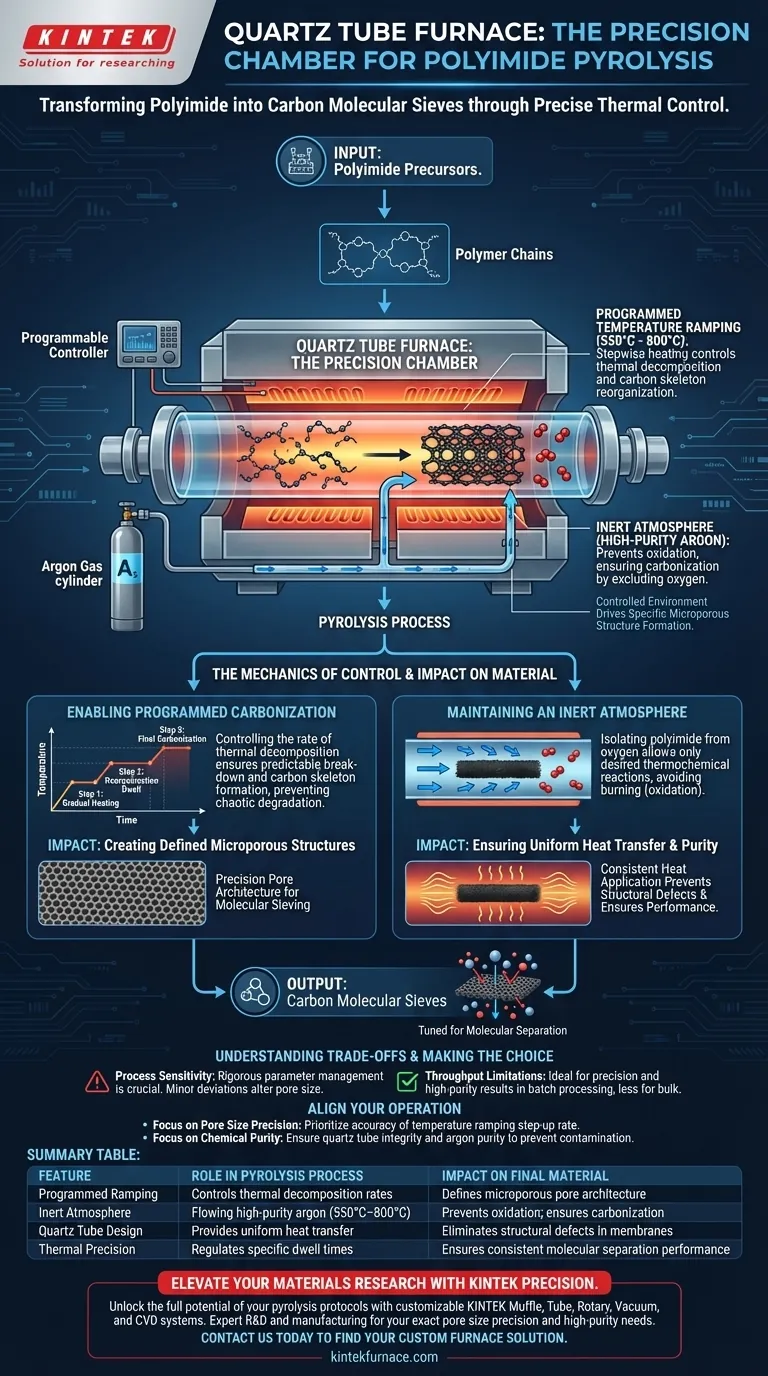

A quartz tube furnace serves as the precision reaction chamber required to transform polyimide precursors into carbon molecular sieves. It acts as a programmable environment that executes specific heating protocols—typically stepping up to temperatures between 550°C and 800°C—while maintaining a high-purity inert atmosphere to drive carbonization without oxidation.

Core Takeaway The furnace is not simply a heating element; it is a structural regulator. Its primary function is to enforce a strictly controlled environment—through precise thermal ramping and argon gas flow—which dictates the formation of the specific microporous structures necessary for molecular separation.

The Mechanics of Control

Enabling Programmed Carbonization

The conversion of polyimide into carbon molecular sieves is not achieved by static heating. The quartz tube furnace facilitates programmed temperature ramping, which allows for a stepwise increase in heat.

This gradual or stepped approach is essential for controlling the rate of thermal decomposition. By managing the heating rate, the furnace ensures the polymer chains break down and reorganize into a carbon skeleton in a predictable manner, rather than degrading chaotically.

Maintaining an Inert Atmosphere

A critical role of the furnace is isolating the polyimide from oxygen. The system utilizes the quartz tube to contain a flowing atmosphere of high-purity argon.

If oxygen were present at these temperatures (550°C–800°C), the material would simply burn (oxidize) rather than carbonize. The furnace ensures the environment remains strictly inert, allowing only the desired thermochemical reactions to occur.

Impact on Material Properties

Creating Defined Microporous Structures

The ultimate goal of this process is to create a material that can "sieve" molecules based on size. The precision of the furnace directly correlates to the pore architecture of the final product.

By adhering to exact temperature profiles and dwell times, the furnace facilitates the development of a specific micropore network. This is particularly crucial for creating fluorine-customized carbon molecular sieves, where the internal structure must be tuned to exact specifications.

Ensuring Uniform Heat Transfer

While the chemical reaction is paramount, physical consistency is equally important. The design of the tube furnace ensures that heat is applied uniformly across the precursor membrane.

This uniformity prevents structural defects or uneven carbonization, which would compromise the separation performance of the final molecular sieve.

Understanding the Trade-offs

Process Sensitivity

The reliance on a quartz tube furnace introduces a requirement for rigorous parameter management. Because the microporous structure is dictated by the thermal history, even minor deviations in the heating ramp or gas flow can alter the pore size, rendering the sieve ineffective for its intended target molecule.

Throughput Limitations

Quartz tube furnaces are typically batch-processing tools ideal for precision and high-purity results. They provide exceptional control for creating high-value materials like carbon molecular sieves, but they generally offer lower throughput compared to continuous industrial kilns used for bulk materials.

Making the Right Choice for Your Goal

To maximize the effectiveness of your pyrolysis process, align your furnace operation with your specific objectives:

- If your primary focus is Pore Size Precision: Prioritize the accuracy of your temperature ramping program; the step-up rate defines the final microporous structure.

- If your primary focus is Chemical Purity: Ensure the integrity of the quartz tube and the purity of the argon gas source to prevent surface oxidation or contamination.

Success in converting polyimide to carbon molecular sieves relies less on peak temperature and more on the precise environmental control that a quartz tube furnace provides.

Summary Table:

| Feature | Role in Pyrolysis Process | Impact on Final Material |

|---|---|---|

| Programmed Ramping | Controls thermal decomposition rates | Defines microporous pore architecture |

| Inert Atmosphere | Flowing high-purity argon (550°C–800°C) | Prevents oxidation; ensures carbonization |

| Quartz Tube Design | Provides uniform heat transfer | Eliminates structural defects in membranes |

| Thermal Precision | Regulates specific dwell times | Ensures consistent molecular separation performance |

Elevate Your Materials Research with KINTEK Precision

Unlock the full potential of your pyrolysis protocols with KINTEK’s high-performance thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of polyimide-to-carbon conversion and other advanced lab processes.

Whether you require exact pore size precision or high-purity inert environments, our systems deliver the uniform heating and programmable control your research deserves. Contact us today to find your custom furnace solution and see how our expertise can accelerate your innovation.

Visual Guide

References

- Shan Xu, Yunlong Ji. High‐Performance Carbon Capture with Fluorine‐Tailored Carbon Molecular Sieve Membranes. DOI: 10.1002/adma.202420477

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-purity quartz tube furnace play in graphene growth? Achieve Conformal Optical Resonator Coating

- What role does a high-temperature tube furnace play in the preparation of biomimetic composite skeletons?

- Why is uniform heating important in horizontal furnaces? Ensure Material Quality and Process Efficiency

- What advanced materials research applications involve tube furnaces? Unlock Precision for Next-Gen Materials

- How do researchers utilize the heating elements in tubular furnaces? Unlock Precise Thermal Control for Advanced Materials Research

- What additional features might a split tube furnace have? Boost Your Lab's Precision and Control

- What are the key benefits of using split tube furnaces? Unlock Superior Access and Control for Your Lab

- How does a high-temperature tube furnace facilitate the ammonolysis process? Master TiNx Nanoparticle Synthesis