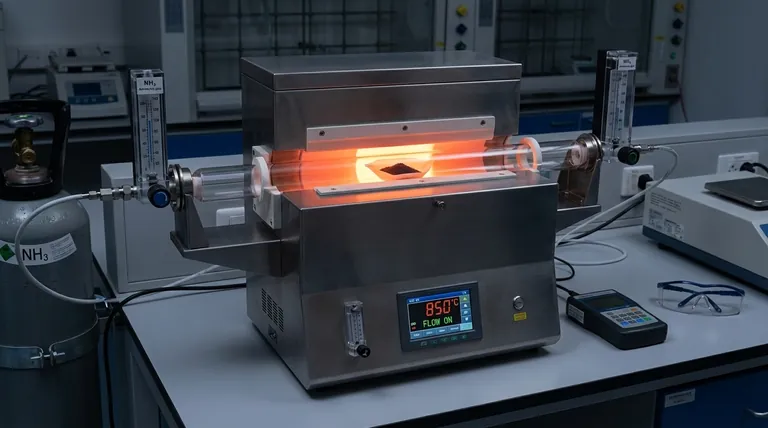

A high-temperature tube furnace facilitates the ammonolysis process by establishing a controlled thermal reactor where a continuous stream of ammonia gas can interact with a precursor material, specifically MIL-125(Ti). This setup allows for precise heating between 500 °C and 900 °C, which is necessary to drive the chemical conversion of the precursor into titanium nitride (TiNx) nanoparticles while simultaneously tuning their electronic properties.

Core Takeaway The tube furnace is not merely a heating element; it is a flow reactor that enables the complete nitridation of MIL-125(Ti). Its primary value lies in the ability to regulate nitrogen vacancy concentrations through temperature adjustments, which is the deciding factor in the sensitivity and performance of the resulting sensors.

The Role of the Tube Furnace Environment

Enabling Continuous Gas Flow

Unlike static heating chambers, a tube furnace is designed to manage a dynamic atmosphere.

It allows for the continuous introduction of ammonia gas throughout the heating cycle.

This constant flow ensures that fresh reactant (ammonia) is always available to interact with the solid precursor, driving the reaction to completion.

Precise Thermal Regulation

The furnace maintains a stable environment within a specific target range, generally 500 °C to 900 °C.

This stability is critical because the conversion from a metal-organic framework like MIL-125(Ti) to a nitride ceramic requires sustained, high-energy thermal input to break existing bonds and form new titanium-nitrogen bonds.

The Mechanism of Ammonolysis

Transforming the Precursor

The process begins with MIL-125(Ti), a titanium-based metal-organic framework.

Under the influence of heat and reactive ammonia, the organic components of the framework decompose.

Simultaneously, the titanium centers undergo nitridation, chemically bonding with nitrogen derived from the ammonia gas to form TiNx nanoparticles.

Tuning Material Properties

The tube furnace does more than simply synthesize the material; it acts as a tuning tool for the material's microstructure.

By strictly controlling the temperature, you directly influence the concentration of nitrogen vacancies (defects) in the crystal lattice.

These vacancies are essential because they alter the electronic structure of the nanoparticles, directly enhancing their activity for sensor applications.

Understanding the Trade-offs

Temperature Sensitivity

While the furnace allows for tuning, the process is highly sensitive to the selected temperature point.

Operating at the lower end (near 500 °C) may result in incomplete nitridation or insufficient crystallinity.

Conversely, operating at the higher end (approaching 900 °C) fundamentally changes the defect density.

Balancing Activity and Stability

There is often a trade-off between high catalytic activity and structural stability.

Higher temperatures typically induce higher crystallinity, which is beneficial for stability, but varying the temperature to maximize nitrogen vacancies requires precise calibration to avoid sintering (clumping) the nanoparticles, which would reduce their effective surface area.

Making the Right Choice for Your Goal

To optimize your TiNx synthesis, align your furnace parameters with your specific performance targets:

- If your primary focus is material conversion: Ensure a consistent ammonia flow and maintain temperatures above 500 °C to guarantee the complete transformation of MIL-125(Ti) into TiNx.

- If your primary focus is sensor performance: Systematically vary the temperature between 500 °C and 900 °C to find the "sweet spot" that maximizes nitrogen vacancy concentrations for your specific analyte.

Success in ammonolysis depends not just on reaching high temperatures, but on precisely controlling the thermal profile to engineer the atomic defects that drive performance.

Summary Table:

| Feature | Role in Ammonolysis | Impact on TiNx Synthesis |

|---|---|---|

| Continuous Gas Flow | Maintains ammonia saturation | Ensures complete nitridation of solid precursors |

| Precise Thermal Control | Range of 500°C to 900°C | Breaks MOF bonds and forms new Ti-N bonds |

| Atmosphere Integrity | Controlled dynamic environment | Regulates nitrogen vacancies and crystal defects |

| Thermal Stability | Prevents temperature fluctuations | Controls nanoparticle crystallinity and prevents sintering |

Elevate Your Nanomaterial Research with KINTEK

Achieving the perfect defect density in TiNx nanoparticles requires absolute thermal precision and atmosphere control. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for advanced chemical synthesis like ammonolysis.

Whether you are scaling up production or tuning sensitive electronic properties, our customizable lab high-temp furnaces ensure repeatable, high-purity results every time.

Contact KINTEK today to discuss your unique synthesis needs

Visual Guide

References

- Xuefei Zhao, Minghui Yang. Titanium nitride sensor for selective NO2 detection. DOI: 10.1038/s41467-024-55534-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the basic working principle of a tube furnace? Master Precise Heating for Material Processing

- What are the benefits of using an alumina tube furnace? Achieve Pure, High-Temp Material Processing

- What is the role of a laboratory tube furnace in teaching and training? Enhance Student Learning with Hands-On Thermal Experiments

- What core environmental conditions does a laboratory tube furnace provide for MoS2 sulfurization? Master 750 °C Synthesis

- Why is it important to calibrate the temperature profile of a tube furnace? Ensure Accurate and Repeatable Results

- What are the primary functions of a high-performance tube furnace in the two-stage synthesis of Ln-MoP@C catalysts?

- What is the function of Argon gas flow within a Tube Furnace during the heat treatment of Molybdenum Disulfide? Expert Guide

- Why are controlled atmosphere and vacuum operations important for tube furnaces? Protect Materials and Enable Precision Reactions