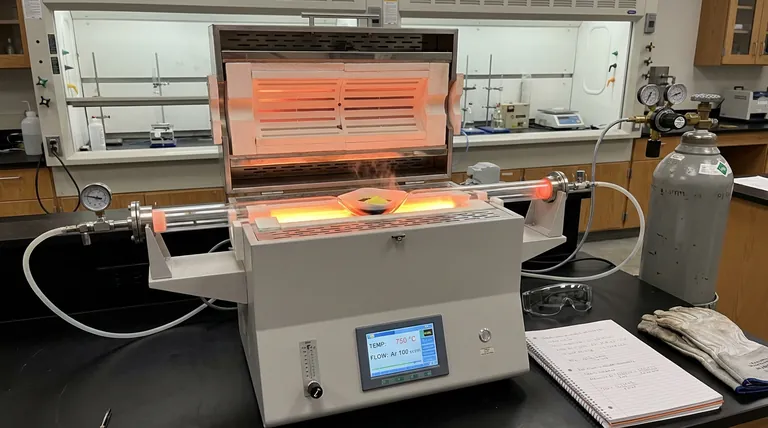

A laboratory tube furnace creates three essential environmental conditions for this process: a highly stable reaction chamber maintained at 750 °C, precise regulation of Argon (Ar) gas flow, and the ability to cycle between vacuum and atmospheric pressure. These conditions are engineered to facilitate a specific heterogeneous chemical reaction between gaseous sulfur and liquid sodium molybdate.

The tube furnace is not simply a heat source; it provides a uniform thermal field that synchronizes crystal nucleation. This precision is the deciding factor in converting reactive precursors into high-quality, large-area Molybdenum Disulfide (MoS2) crystals.

Creating the Reaction Environment

Facilitating Heterogeneous Reactions

The 750 °C sulfurization process relies on a complex interaction between materials in different states: gaseous sulfur and liquid sodium molybdate.

The tube furnace uses programmed heating to bring these precursors to the correct temperature simultaneously. This precise thermal ramp allows the heterogeneous reaction to occur efficiently at the interface of the liquid and gas phases.

Atmosphere and Pressure Management

To prevent unwanted oxidation and control reaction kinetics, the furnace provides a sealed environment capable of cycling between vacuum and atmospheric pressure.

Once the chamber is purged, the system maintains a controlled flow of Argon (Ar) gas. This inert atmosphere is critical for stabilizing the volatile sulfur vapor and protecting the developing MoS2 layers.

The Criticality of Thermal Uniformity

Synchronized Nucleation

The most significant contribution of the tube furnace to this process is thermal field uniformity.

Uniform heat distribution ensures that nucleation—the birth of the crystal—happens simultaneously across the substrate. Without this synchronization, crystal growth would be chaotic and patchy.

Promoting Large-Area Growth

The furnace design creates a constant temperature zone that minimizes longitudinal temperature gradients.

By eliminating cold spots or heat spikes, the furnace allows MoS2 crystals to grow continuously. This results in the formation of large-area crystals rather than fragmented, microscopic islands.

Understanding the Trade-offs

Sensitivity to Equilibrium

While tube furnaces offer excellent uniformity, they are highly sensitive to disturbances in thermal equilibrium.

Rapid changes in gas flow or heating rates can disrupt the stable environment required for the liquid-gas reaction. The user must strictly adhere to programmed rates to prevent thermal shock or uneven reaction fronts.

Constraint of the Constant Zone

The "constant temperature zone" where high-quality growth occurs is finite (e.g., often around 80 mm in standard models).

This limits the size of the sample you can process in a single batch. Attempting to process samples larger than this zone will result in gradient-induced defects at the sample edges.

Making the Right Choice for Your Goal

To maximize the quality of your MoS2 synthesis, you must align the furnace capabilities with your specific output requirements.

- If your primary focus is crystal uniformity and size: Prioritize a furnace with a verified, extended constant temperature zone to ensure synchronized nucleation across the entire substrate.

- If your primary focus is reaction purity: Ensure the system has high-precision vacuum and Argon flow controls to perfectly manage the heterogeneous reaction environment.

Mastering the interplay between a uniform thermal field and precise atmospheric control is the key to reproducible MoS2 synthesis.

Summary Table:

| Environmental Factor | Requirement for MoS2 Sulfurization | Benefit to Crystal Quality |

|---|---|---|

| Temperature | Stable 750 °C Constant Zone | Synchronized nucleation and large-area growth |

| Atmosphere | Inert Argon (Ar) Gas Flow | Prevents oxidation and stabilizes sulfur vapor |

| Pressure | Vacuum to Atmospheric Cycling | Purges impurities and manages reaction kinetics |

| Reaction Type | Heterogeneous (Gas-Liquid) | Facilitates interaction between S vapor and Na2MoO4 |

Elevate Your Material Synthesis with KINTEK Precision

Ready to achieve superior thermal uniformity for your MoS2 sulfurization? KINTEK provides industry-leading Tube, Muffle, Vacuum, and CVD systems designed for the most demanding laboratory environments. Backed by expert R&D and precision manufacturing, our furnaces are fully customizable to meet your unique temperature and atmospheric requirements.

Don't let thermal gradients compromise your research. Contact KINTEK today to discuss your custom furnace solution and ensure reproducible, high-quality results for your lab.

References

- Zhunda Zhu, Nagahiro Saito. Two-Dimensional Crystal Growth of MoS2 Thin Films from Sodium Dodecyl Sulfate Micellar Solutions and Wettability Between Solution and Substrate. DOI: 10.3390/coatings15010004

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is an inert atmosphere tube furnace required for P3-type layered oxide synthesis? Ensure Pure Crystal Structures

- What role does a tubular furnace play in the thermal activation of sulfide ores? Precision Control for High-Yield Leaching

- What conditions does a tube furnace provide for post-ion-implantation? Achieve Precise Microstructural Repair

- How does a vacuum tube furnace serve as the core equipment in the consolidation of Ti-xCr-2Ge alloys?

- What temperature range and applications is this tube furnace suitable for? Ideal for 500°C to 1800°C thermal processes

- What are the key features of tube furnaces? Unlock Precision in High-Temperature Processing

- What is the role of a laboratory tube furnace in teaching and training? Enhance Student Learning with Hands-On Thermal Experiments

- What is the specific function of a high-temperature tube furnace for MXene-NiCo2Se4? Master the Selenization Process