In short, a tube furnace is suitable for processes typically ranging from 500°C to 1800°C. Its primary advantage is the ability to perform these thermal processes—such as material synthesis, sintering, and annealing—within a tightly controlled atmosphere or vacuum, making it indispensable for advanced materials research and specialized industrial applications.

The key takeaway is not the temperature itself, but the furnace's ability to isolate a sample from the ambient air. This environmental control is the fundamental reason it is chosen for sensitive processes where purity, oxidation prevention, or specific chemical reactions are critical.

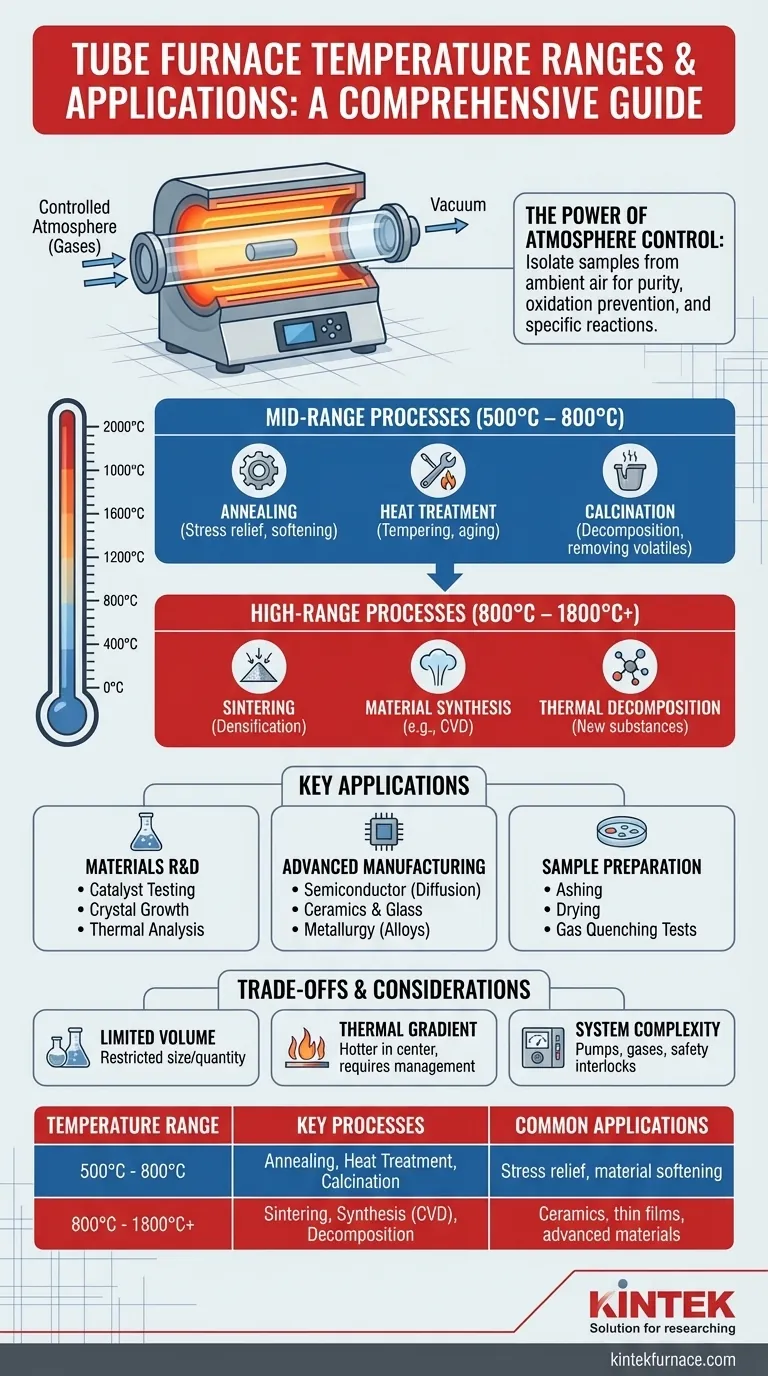

Why a Tube Furnace? The Power of Atmosphere Control

The defining feature of a tube furnace is its cylindrical chamber. This tube, typically made of quartz, alumina, or mullite, serves as a contained environment for the sample.

This design allows you to remove the air to create a vacuum or introduce specific gases to create a protective or reactive atmosphere. This capability is impossible in a standard box furnace and is central to the applications a tube furnace excels at.

Mapping Temperature Ranges to Core Processes

The required temperature is dictated entirely by the material and the desired outcome. Applications can be broadly grouped into two temperature regimes.

Mid-Range Processes (500°C – 800°C)

This range is primarily used for modifying the properties of existing materials without melting them.

- Annealing: Heating and holding a material at a suitable temperature, followed by slow cooling. This is done to relieve internal stresses, increase softness and ductility, and refine the crystal structure.

- Heat Treatment: A broader category that includes processes like tempering or aging to achieve specific mechanical properties in metals and alloys.

- Calcination: Decomposing a material or removing volatile compounds (like water) through heating in a controlled atmosphere.

High-Range Processes (800°C – 1800°C+)

This higher temperature range is necessary for creating new materials or fundamentally changing their structure.

- Sintering: Fusing powders together into a solid, dense mass by heating them below their melting point. This is a cornerstone of ceramic and powder metallurgy processing.

- Material Synthesis: Creating new compounds or materials. A prime example is Chemical Vapor Deposition (CVD), where gases react at high temperatures to deposit a thin film onto a substrate.

- Thermal Decomposition: Breaking down chemical compounds with heat to produce new substances, such as preparing specific oxide, nitride, or carbide materials.

Key Applications in Research and Industry

The combination of precise temperature and atmosphere control makes the tube furnace a versatile tool across many fields.

Materials Research & Development

Laboratories rely on tube furnaces for foundational research. This includes catalyst testing to evaluate activity, crystal growth under specific conditions, and studying material behavior at high temperatures for thermal analysis.

Advanced Manufacturing

In industry, tube furnaces are critical for production. Semiconductor manufacturing uses them for diffusion and oxidation steps, while the ceramics and glass industries use them for processing and heat treatment. They are also vital in metallurgy for creating specialized alloys.

Sample Preparation

Tube furnaces are also used for preparing samples for other forms of analysis. This includes ashing (burning off organic matter), drying samples in a controlled environment, and performing gas quenching tests to study material responses to rapid cooling.

Understanding the Trade-offs

While powerful, a tube furnace is not a universal solution. Understanding its limitations is key to using it effectively.

Limited Sample Volume

The tube's diameter naturally restricts the size and quantity of the material you can process at one time. For large-batch processing, a box or batch furnace may be more appropriate, provided atmosphere control is not needed.

Thermal Gradient

A temperature gradient often exists along the length of the tube, with the center being the hottest. While multi-zone furnaces with multiple heaters can create a longer, more uniform hot zone, it remains a critical factor to manage for consistent results.

System Complexity

Operating a tube furnace safely and effectively requires managing not just the temperature controller but also the vacuum pumps, gas lines, flow meters, and safety interlocks. This adds a layer of operational complexity compared to a simple air furnace.

Making the Right Choice for Your Goal

Select your thermal processing equipment based on the specific outcome you need to achieve.

- If your primary focus is modifying an existing material (e.g., softening metal): An annealing process in the 500-800°C range with an inert atmosphere to prevent scaling is your solution.

- If your primary focus is creating a new solid from powder (e.g., making a ceramic part): You require a sintering process in the 800-1800°C range, often under vacuum or a specific atmosphere.

- If your primary focus is depositing a thin film or growing crystals: A process like CVD is necessary, leveraging high temperatures and precise reactive gas control.

- If your primary focus is simply heating a stable material in air: A less complex and often larger capacity box furnace may be a more efficient choice.

Ultimately, a tube furnace is the definitive tool when the environment around your sample is just as important as the temperature.

Summary Table:

| Temperature Range | Key Processes | Common Applications |

|---|---|---|

| 500°C - 800°C | Annealing, Heat Treatment, Calcination | Stress relief in metals, material softening, decomposition |

| 800°C - 1800°C+ | Sintering, Material Synthesis (e.g., CVD), Thermal Decomposition | Ceramics production, thin film deposition, advanced materials creation |

Unlock precise thermal processing with KINTEK's advanced tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met for superior results in materials research and industrial applications. Contact us today to discuss how our high-temperature furnace solutions can elevate your work!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity