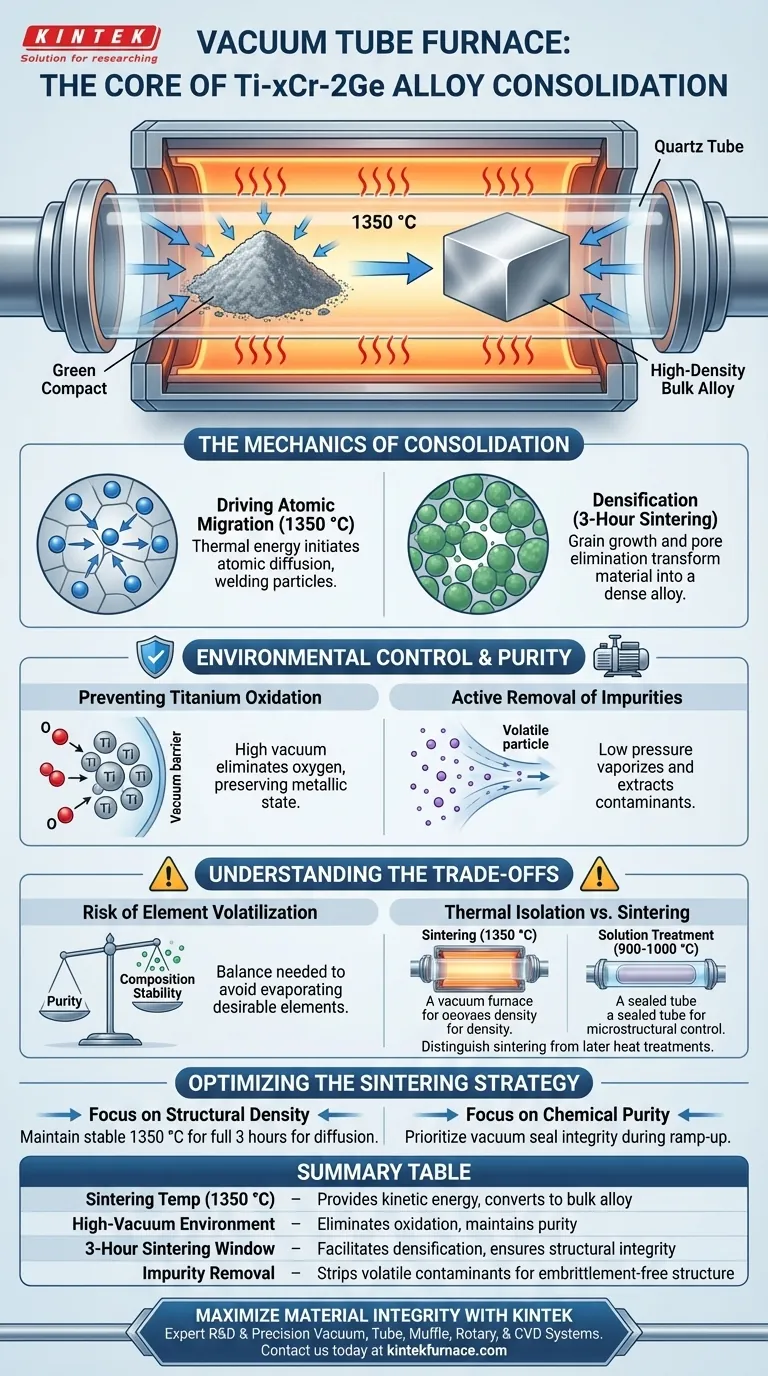

The vacuum tube furnace serves as the definitive sintering engine for the final consolidation of Ti-xCr-2Ge alloys. By maintaining a precise temperature of 1350 °C within a high-vacuum environment for three hours, it facilitates the critical atomic diffusion required to transform loose powder "green compacts" into dense, structural bulk alloys while strictly preventing oxidation.

The furnace creates a dual-purpose environment: high thermal energy drives the physical bonding of grains to eliminate porosity, while the vacuum atmosphere actively shields the reactive titanium matrix from oxygen and removes volatile impurities.

The Mechanics of Consolidation

Driving Atomic Migration

The primary function of the furnace is to provide the thermal energy necessary to initiate atomic movement.

At the specific sintering temperature of 1350 °C, the atoms within the titanium alloy powder gain enough kinetic energy to migrate across particle boundaries.

This migration is not merely melting; it is a diffusion process where atoms move from areas of high concentration to low concentration, effectively welding the particles together at a microscopic level.

Densification of Green Compacts

Before entering the furnace, the alloy exists as a "green compact"—a pressed shape of loose powder held together only by mechanical interlocking.

During the 3-hour sintering window, the furnace heat causes the grains to grow and the voids (pores) between them to shrink and vanish.

This transforms the material from a fragile, porous object into a high-density bulk alloy with structural integrity.

Environmental Control and Purity

Preventing Titanium Oxidation

Titanium and its alloys are highly reactive to oxygen, especially at elevated temperatures.

Without a vacuum environment, heating titanium to 1350 °C would result in rapid oxidation, destroying the material's mechanical properties.

The vacuum tube furnace eliminates atmospheric oxygen, ensuring the titanium matrix remains metallic and chemically pure throughout the consolidation process.

Active Removal of Impurities

Beyond simple protection, the high-vacuum setting plays an active role in purification.

The low pressure lowers the boiling point of certain contaminants, allowing them to vaporize and be drawn out of the material.

This ensures that the final integrated alloy is free from interstitial impurities that could embrittle the structure.

Understanding the Trade-offs

The Risk of Element Volatilization

While high vacuum is essential for purity, it presents a challenge regarding alloy composition stability.

Just as the vacuum helps remove impurities, it can also lower the evaporation point of desirable alloying elements if the pressure is too low or the temperature too high.

Operators must balance the need for impurity removal against the risk of evaporating specific alloying components, which would alter the final stoichiometry of the Ti-xCr-2Ge alloy.

Thermal Isolation vs. Sintering

It is important to distinguish this consolidation process from subsequent heat treatments.

While the vacuum tube furnace is used for sintering (consolidation) at 1350 °C, other processes like solution treatment often utilize sealed quartz tubes in box furnaces at lower temperatures (900–1000 °C).

The vacuum furnace is the heavy lifter for density, while sealed tube methods are often preferred later for precise microstructural control to prevent element loss during prolonged holding times.

Optimizing the Sintering Strategy

To achieve the best results with Ti-xCr-2Ge alloys, align your process parameters with your specific material goals:

- If your primary focus is structural density: Ensure the furnace maintains a stable 1350 °C for the full 3-hour duration to maximize atomic diffusion and pore elimination.

- If your primary focus is chemical purity: Prioritize the integrity of the vacuum seal to prevent titanium oxidation and effectively strip volatile impurities during the heat ramp-up.

Success in consolidating these alloys relies on using the vacuum tube furnace not just as a heater, but as a precision tool for atmospheric control and atomic management.

Summary Table:

| Process Parameter | Role in Ti-xCr-2Ge Consolidation | Impact on Final Alloy |

|---|---|---|

| Sintering Temp (1350 °C) | Provides kinetic energy for atomic migration | Converts green compacts into dense bulk alloys |

| High-Vacuum Environment | Eliminates atmospheric oxygen and nitrogen | Prevents oxidation and maintains chemical purity |

| 3-Hour Sintering Window | Facilitates grain growth and pore elimination | Ensures structural integrity and high density |

| Impurity Removal | Lowers boiling point of contaminants | Strips volatile impurities for an embrittlement-free structure |

Maximize Material Integrity with KINTEK

Ensure the highest density and purity for your advanced materials. KINTEK provides industry-leading Vacuum, Tube, Muffle, Rotary, and CVD systems, all backed by expert R&D and precision manufacturing. Whether you are sintering reactive titanium alloys or developing custom CVD processes, our equipment is fully customizable to meet your unique laboratory needs.

Ready to elevate your research? Contact us today to discover how our high-temperature furnace solutions can bring precision and reliability to your laboratory.

Visual Guide

References

- Teddy Sjafrizal, Matthew S. Dargusch. Powder Metallurgy Preparation of Metastable <i>β</i> Ti–Cr–Ge Alloys for Medical Applications. DOI: 10.1002/adem.202500563

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the pros and cons of vertical tube furnaces? Precision vs. Capacity for Your Lab

- What are the applications of a tube furnace? Master Precise Thermal Processing for Advanced Materials

- What is the function of a tube reactor during the reduction process of Siderite Ore? Optimize Your Metallization Process

- What role does a vacuum tube furnace play as a reactor during the coal gasification reaction stage?

- Why is calibration important for a horizontal electric furnace? Ensure Precise Temperature Control for Your Materials

- How is the atmosphere controlled in a vacuum tube furnace? Achieve Precise Gas Environments for Your Experiments

- Why is a secondary high-temperature activation process in a tube furnace necessary? Converting Biochar into CBAC

- What is the purpose of flushing a tube furnace with high-purity argon for hours? Ensure Pure Silicon Steel Results