In essence, vertical tube furnaces provide exceptional temperature uniformity and a clean processing environment at the cost of smaller sample capacity and higher investment. They excel in applications where precision and purity are paramount, such as semiconductor manufacturing or advanced materials research, but are less suited for high-volume bulk processing.

The decision between a vertical and horizontal tube furnace is not about which is inherently better, but which design philosophy aligns with your primary goal. The choice boils down to a fundamental trade-off: processing precision and purity versus batch size and throughput.

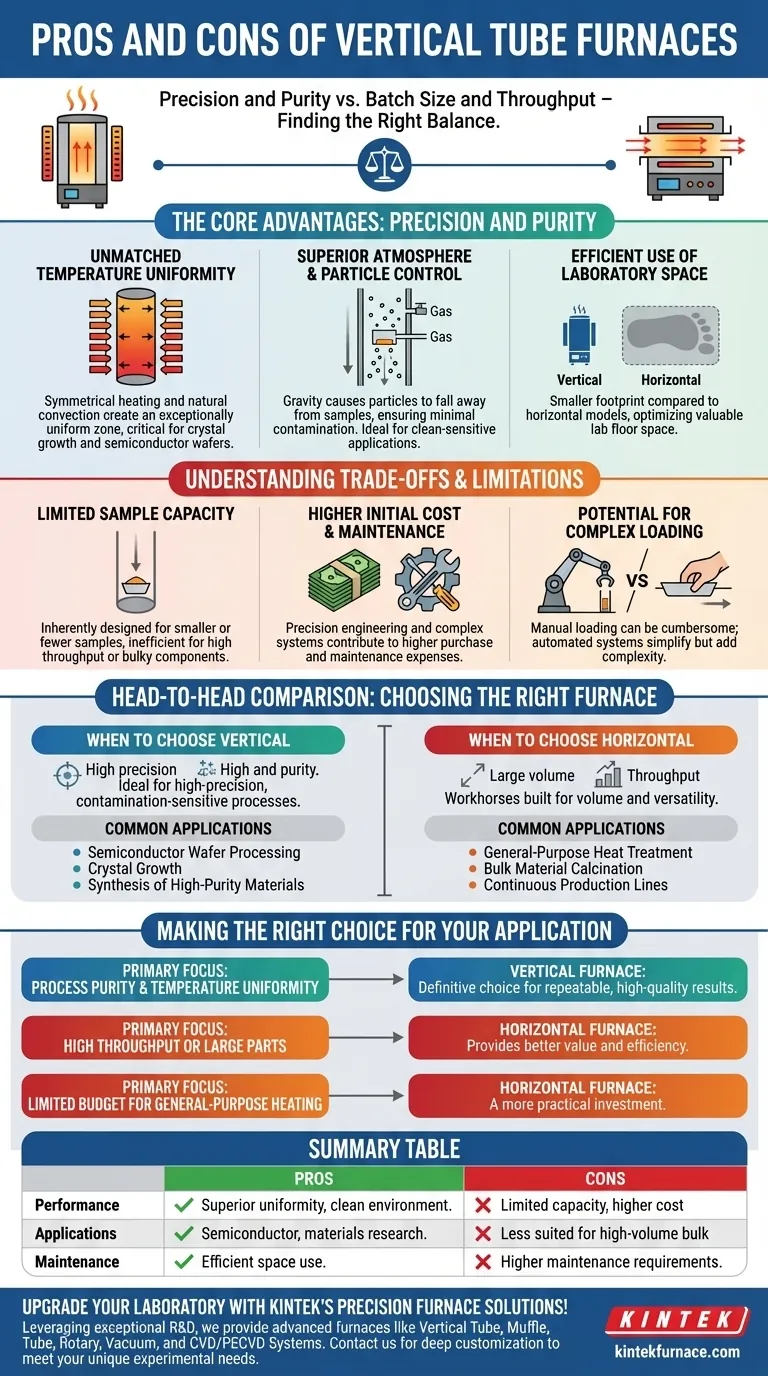

The Core Advantages: Precision and Purity

A vertical tube furnace's primary benefits stem directly from its orientation. By aligning the heating chamber with gravity, it achieves performance characteristics that are difficult to replicate in a horizontal setup.

Unmatched Temperature Uniformity

The vertical design allows for highly symmetrical heating elements to surround the process tube. This, combined with natural convection, creates an exceptionally uniform temperature zone along the length of the sample.

This level of thermal consistency is critical for processes like crystal growth, annealing semiconductor wafers, or synthesizing advanced materials where even minor temperature deviations can compromise the final product. The result is highly consistent and repeatable outcomes.

Superior Atmosphere and Particle Control

In a vertical furnace, any particles shed from the furnace interior or sample holders fall downwards due to gravity, away from the sample. This minimal particle generation is a significant advantage in clean-sensitive applications.

Furthermore, these furnaces are easily integrated with vacuum systems and multiple gas flow controllers. This enables precise atmosphere control, allowing for processes to occur in inert (oxygen-free) or reactive gas environments.

Efficient Use of Laboratory Space

The upright design gives vertical tube furnaces a significantly smaller footprint compared to their horizontal counterparts. For laboratories where floor space is at a premium, this is a major practical benefit.

Understanding the Trade-offs and Limitations

The specialized design of a vertical furnace introduces constraints that make it unsuitable for certain applications. Understanding these trade-offs is crucial for making an informed investment.

Limited Sample Capacity

The most significant drawback is a smaller working capacity. Vertical furnaces are inherently designed for smaller or fewer samples compared to horizontal models of a similar class.

This limitation makes them inefficient for applications requiring high throughput or the processing of large, bulky components.

Higher Initial Cost and Maintenance

The precision engineering, advanced control systems, and often automated loading mechanisms contribute to a higher initial purchase price.

Additionally, the complexity of these systems can lead to higher maintenance requirements and associated costs over the furnace's lifetime.

Potential for Complex Loading

While automated systems can simplify sample handling, manual loading and unloading of a vertical tube can be more cumbersome than simply sliding a sample boat into a horizontal furnace. This depends heavily on the specific model and the nature of the samples being processed.

Vertical vs. Horizontal: A Head-to-Head Comparison

Choosing the right furnace requires aligning its strengths with your specific application needs.

When to Choose a Vertical Furnace

Vertical furnaces are the ideal choice for high-precision, contamination-sensitive processes. Their superior temperature control and low particle environment are essential for industries producing high-value materials.

Common applications include semiconductor wafer processing (diffusion, oxidation), crystal growth, and the synthesis of high-purity powders and nanomaterials.

When to Choose a Horizontal Furnace

Horizontal furnaces are workhorses built for volume and versatility. They offer a larger working volume, accommodating bigger samples or multiple smaller samples in a single batch.

They are better suited for general-purpose heat treatment, bulk material calcination, and continuous production lines where throughput is more critical than absolute particle control.

Making the Right Choice for Your Application

Your final decision should be guided by the single most important factor in your process.

- If your primary focus is process purity and absolute temperature uniformity: The superior control and low-particle environment of a vertical furnace is the definitive choice for repeatable, high-quality results.

- If your primary focus is high throughput or processing large parts: The larger capacity and flexibility of a horizontal furnace will provide better value and efficiency.

- If your primary focus is a limited budget for general-purpose heating: The added cost and complexity of a vertical furnace are likely unnecessary, and a simpler horizontal model is a more practical investment.

By aligning the furnace's fundamental design with your primary processing goal, you ensure optimal results and a sound investment in your capabilities.

Summary Table:

| Aspect | Pros | Cons |

|---|---|---|

| Performance | Superior temperature uniformity, clean processing environment | Limited sample capacity, higher initial cost |

| Applications | Ideal for semiconductor, materials research | Less suited for high-volume bulk processing |

| Maintenance | Efficient space use | Higher maintenance requirements |

Upgrade your laboratory with KINTEK's precision furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Vertical Tube Furnaces, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior temperature control and purity. Contact us today to discuss how our solutions can enhance your research and efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents