In short, calibration is critical for a horizontal electric furnace because it ensures the temperature you set is the temperature your material actually experiences. Without it, temperature sensors and controllers will inevitably drift over time, leading to inaccurate processing that can compromise or destroy the materials you are working with.

The core purpose of a horizontal furnace is precise thermal control. Calibration is the mandatory practice that guarantees this precision, protecting your process from the gradual and often invisible decay of sensor accuracy. It is not just maintenance; it is fundamental process validation.

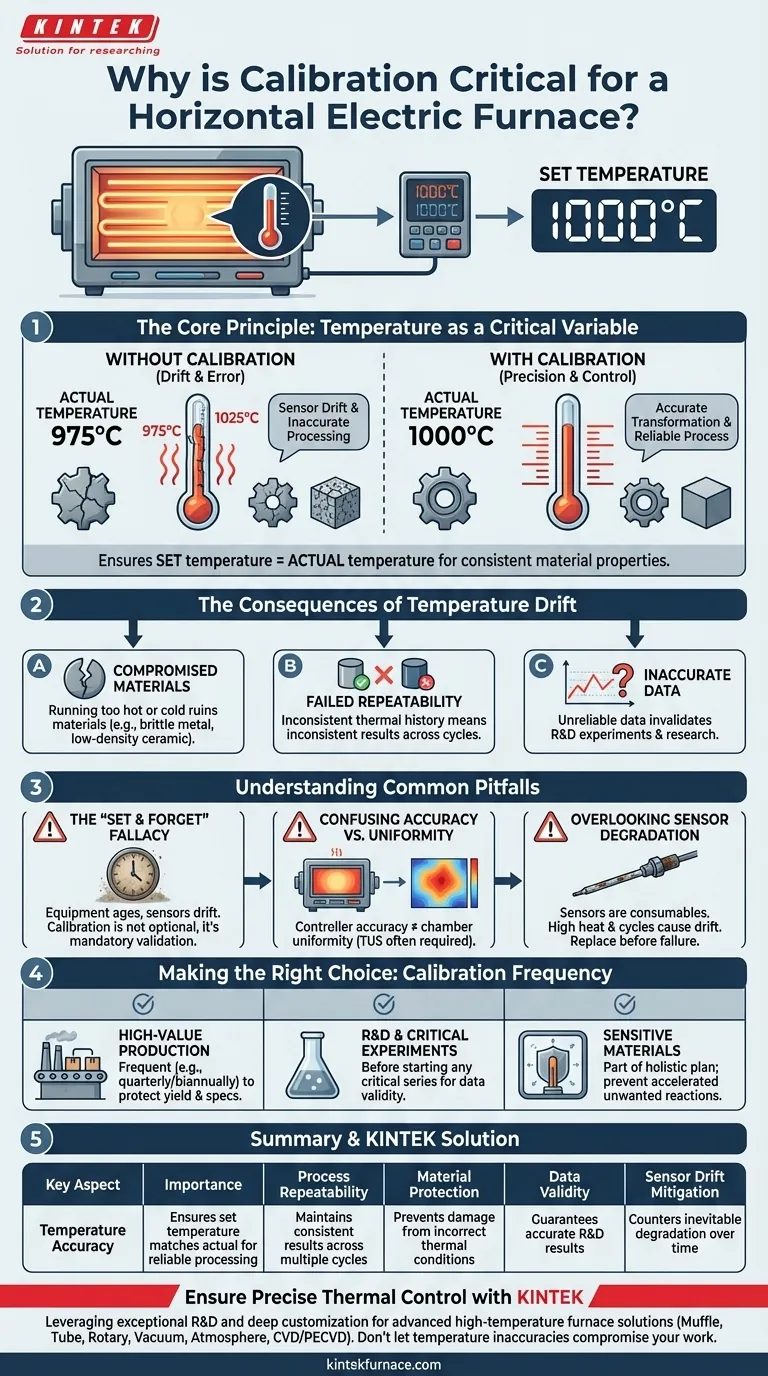

The Core Principle: Temperature as a Critical Variable

A horizontal electric furnace is a precision instrument. Its value comes from creating a highly controlled thermal environment, often enhanced with specific gas atmospheres or a vacuum. The temperature is not just a setting; it is the most critical input that dictates the outcome of your process.

Driving Material Transformation

Nearly every process performed in a furnace—whether annealing, sintering, or growing crystals—relies on temperature to drive specific physical or chemical changes. A deviation of even a few degrees can alter these transformations significantly.

Calibration ensures that the temperature reading on your controller accurately reflects the real temperature inside the furnace chamber. This link is the foundation of a repeatable and reliable process.

Maintaining Process Integrity

The advantages of a horizontal furnace, such as its ability to handle sensitive materials or create controlled atmospheres, are undermined by poor temperature accuracy. An incorrect temperature can lead to incomplete chemical reactions or unintended structural changes, rendering the controlled atmosphere useless.

The Consequences of Temperature Drift

Over time, all temperature sensors, such as thermocouples, degrade. This degradation causes "drift," where the sensor's reading no longer matches the actual temperature. Failing to correct for this drift through calibration has direct and costly consequences.

Compromised Material Properties

This is the most significant risk. A furnace that is running hotter or colder than indicated can ruin the material being processed. For example, a metal part may become too brittle if annealed at the wrong temperature, or a ceramic component may fail to achieve the required density if sintered too low.

Failed Process Repeatability

If you cannot guarantee the furnace is at the same temperature today as it was last week, you cannot achieve consistent results. Calibration synchronizes the furnace to a known standard, ensuring that a setting of 900°C yields the same thermal effect across dozens or hundreds of cycles.

Inaccurate Data and Research

For research and development, inaccurate temperature data invalidates experimental results. Without calibration, you are not testing your material's response to a specific temperature, but to an unknown temperature, making the data unreliable.

Understanding the Common Pitfalls

Trusting the equipment without verification is a common and expensive mistake. Objectivity requires acknowledging where failure points occur.

The "Set and Forget" Fallacy

Many operators assume that once a process is established, the equipment will perform identically forever. However, heating elements age, insulation degrades, and most importantly, temperature sensors drift. Regular calibration is the only way to counteract this inevitable process decay.

Confusing Controller Accuracy with Furnace Uniformity

Calibrating the controller and its primary sensor is essential, but it doesn't guarantee the entire heated zone is at that temperature. A separate process, called a temperature uniformity survey (TUS), may be required to map hot and cold spots within the furnace, which is especially critical for large or long samples.

Overlooking Sensor Degradation

Thermocouples are consumable items. High temperatures, reactive atmospheres, and thermal cycling all contribute to their degradation. Calibration reveals when a sensor has drifted beyond an acceptable limit and needs to be replaced before it can cause a catastrophic process failure.

Making the Right Choice for Your Process

The frequency and rigor of calibration should be directly proportional to the criticality of your process.

- If your primary focus is high-value production: Calibrate frequently (e.g., quarterly or biannually) to protect your yield and ensure every batch meets specification.

- If your primary focus is research and development: Calibrate before starting any critical experiment series to ensure your data is valid and reproducible.

- If your primary focus is processing oxidation-sensitive materials: Ensure calibration is part of a holistic maintenance plan, as temperature deviations can unexpectedly accelerate unwanted chemical reactions even in a controlled atmosphere.

Ultimately, calibration transforms your furnace from a simple heater into a reliable and precise scientific instrument.

Summary Table:

| Key Aspect | Importance |

|---|---|

| Temperature Accuracy | Ensures set temperature matches actual chamber temperature for reliable processing |

| Process Repeatability | Maintains consistent results across multiple cycles by synchronizing to standards |

| Material Protection | Prevents damage or failure of materials due to incorrect thermal conditions |

| Data Validity | Guarantees accurate experimental results in research and development |

| Sensor Drift Mitigation | Counters inevitable degradation of thermocouples and controllers over time |

Ensure your furnace delivers precise thermal control for your lab's success! At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, enhancing process reliability and efficiency. Don't let temperature inaccuracies compromise your work—contact us today to discuss how our tailored solutions can benefit your laboratory!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing