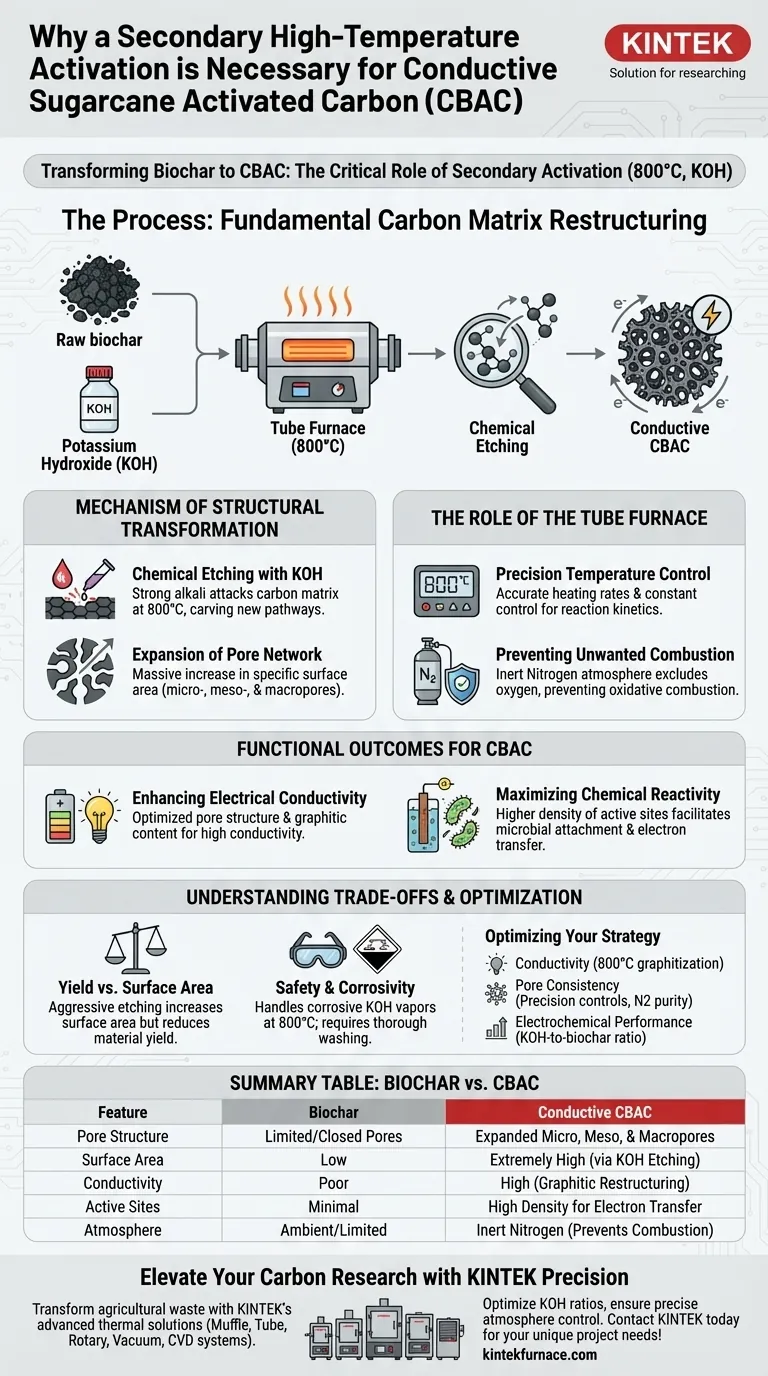

A secondary high-temperature activation process is strictly necessary to fundamentally restructure the carbon matrix of biochar through chemical etching. By subjecting the biochar to temperatures around 800°C in the presence of potassium hydroxide (KOH), the process aggressively expands the material's internal pore network, transforming low-value biochar into highly conductive sugarcane activated carbon (CBAC).

The conversion of biochar to CBAC relies on the aggressive etching of the carbon framework by strong alkalis. This secondary activation drastically increases specific surface area and active sites, creating the physical properties required for high-performance electron transfer in sediment microbial fuel cell anodes.

The Mechanism of Structural Transformation

Chemical Etching with KOH

The core purpose of the secondary process is to facilitate a chemical reaction between the carbonized biochar and an activator, typically potassium hydroxide (KOH).

At high temperatures (approximately 800°C), the strong alkali attacks the carbon matrix. This "etching" process removes carbon atoms in a controlled manner, effectively carving out new pathways within the material.

Expansion of the Pore Network

This etching does not just scratch the surface; it penetrates deep into the material's structure.

The reaction significantly expands internal micropores, mesopores, and macropores. This results in a massive increase in specific surface area, providing vastly more space for chemical interactions compared to raw biochar.

The Role of the Tube Furnace Environment

Precision Temperature Control

A high-precision tube furnace is required to maintain the exact thermal conditions needed for activation.

Accurate heating rates and constant temperature control are essential to drive the reaction kinetics between the activator and the carbon. Without this stability, the etching process becomes inconsistent, leading to poor pore development.

Preventing Unwanted Combustion

The tube furnace allows for the introduction of a continuous, high-purity nitrogen source to create an inert protective atmosphere.

This environment effectively excludes oxygen during the heating process. Without this inert atmosphere, the biochar would undergo oxidative combustion (burning away) rather than activation, destroying the carbon framework instead of refining it.

Functional Outcomes for CBAC

Enhancing Electrical Conductivity

The physical restructuring of the carbon matrix directly influences its electronic properties.

By optimizing the pore structure and graphitic content, the activation process imparts high electrical conductivity. This is a non-negotiable requirement for CBAC when used as an electrode material.

Maximizing Chemical Reactivity

The expanded surface area creates a higher density of active surface sites.

For applications like sediment microbial fuel cell (SMFC) anodes, these active sites are critical. They facilitate the microbial attachment and electron transfer processes that generate power.

Understanding the Trade-offs

Yield vs. Surface Area

The activation process is subtractive; you are essentially burning away parts of the carbon to create holes (pores).

While more aggressive etching increases surface area, it also reduces the overall material yield. There is a delicate balance between achieving maximum porosity and retaining enough structural integrity and mass.

Safety and Corrosivity

Using strong alkalis like KOH at 800°C introduces significant handling challenges.

The process creates corrosive vapors that can damage equipment if not properly managed within the furnace system. The resulting material also requires thorough washing to remove residual chemicals before use.

Optimizing Your Activation Strategy

To ensure you are producing high-quality CBAC suitable for electronic applications, consider your specific performance goals.

- If your primary focus is maximizing conductivity: Ensure the activation temperature reaches 800°C to sufficiently graphitize the carbon and clear pore blockages.

- If your primary focus is pore structure consistency: Prioritize the precision of the tube furnace controls and the purity of the nitrogen atmosphere to prevent uncontrolled oxidation.

- If your primary focus is electrochemical performance: Focus on the KOH-to-biochar ratio to maximize the creation of active surface sites without destroying the bulk material.

Mastering the secondary activation process is the definitive step in turning agricultural waste into a high-value electronic component.

Summary Table:

| Feature | Biochar (Pre-Activation) | Conductive Activated Carbon (CBAC) |

|---|---|---|

| Pore Structure | Limited/Closed Pores | Expanded Micro, Meso, & Macropores |

| Surface Area | Low | Extremely High (via KOH Etching) |

| Conductivity | Poor | High (Graphitic Restructuring) |

| Active Sites | Minimal | High Density for Electron Transfer |

| Atmosphere | Ambient/Limited | Inert Nitrogen (Prevents Combustion) |

Elevate Your Carbon Research with KINTEK Precision

Transform agricultural waste into high-performance electronic components with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of chemical etching and high-temperature activation.

Whether you are optimizing KOH-to-biochar ratios or requiring precise atmosphere control to prevent oxidative combustion, our laboratory furnaces provide the stability and durability your research deserves.

Ready to scale your material synthesis? Contact KINTEK today to discuss your unique project needs with our technical specialists!

Visual Guide

References

- Yanan Zhao, Jian Wang. Magnetically recoverable bagasse-activated carbon composite anodes for sediment microbial fuel cells: enhanced performance in chromium-contaminated soil remediation. DOI: 10.1039/d5ra02890f

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- What factors should be considered when choosing tube furnace cracking? Optimize Your Thermal Decomposition Process

- What are the temperature capabilities of tube furnaces? Find the Perfect Heat for Your Process

- What is the function of a high-temperature tube furnace in the annealing treatment of ZnIn electrodes?

- What technical conditions does a laboratory tube furnace provide for MXene/MWCNTs@C–Co? Master Thermal Synthesis

- What metallurgical processes benefit from tube furnaces? Achieve Precise Heat Treatment and Material Control

- How is the sealing condition achieved in a vacuum tube experimental furnace? Master Precise Atmosphere Control

- What are the main advantages of using a tube furnace in industrial and laboratory settings? Achieve Precise Temperature and Atmosphere Control

- What are the functional advantages of utilizing a high-temperature vertical tube quartz reactor for MoS2/rGO pyrolysis?