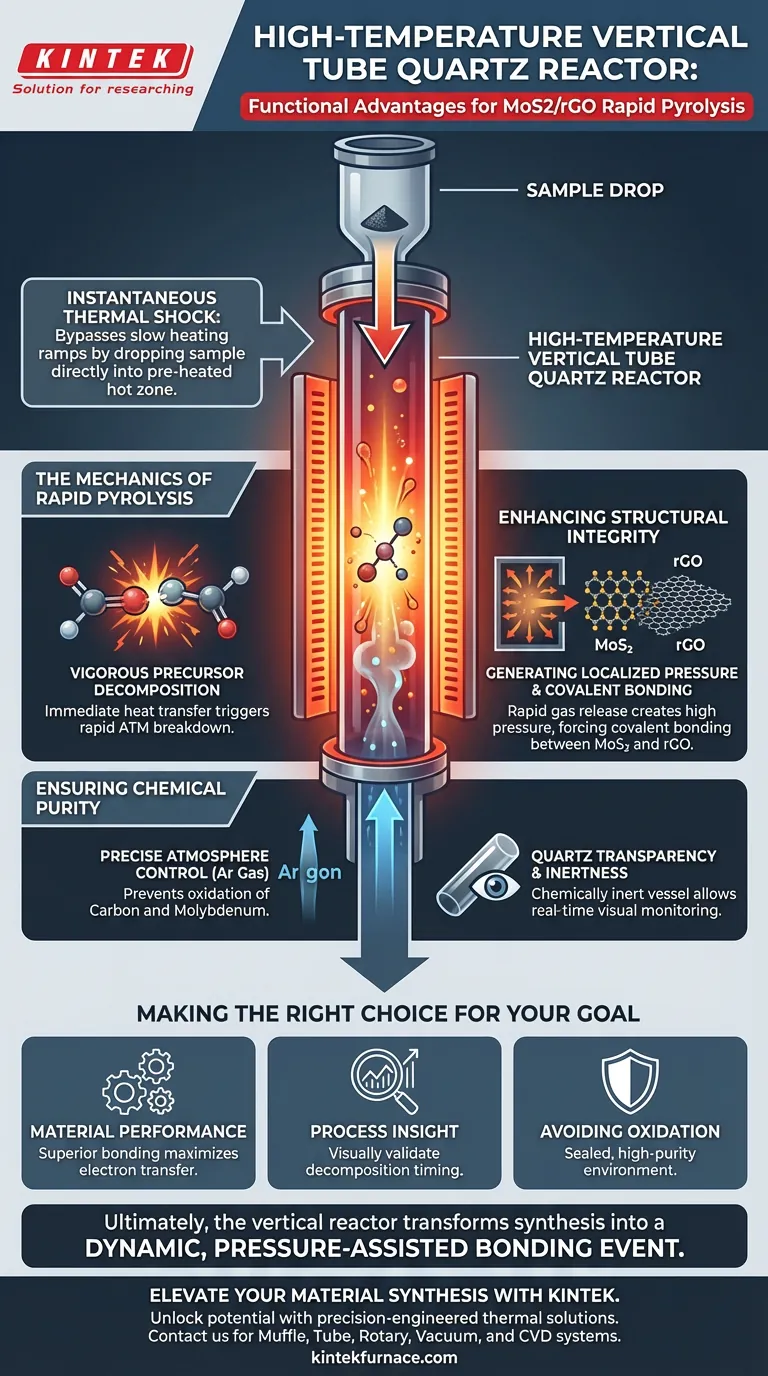

The primary functional advantage of a high-temperature vertical tube quartz reactor is its ability to facilitate the instantaneous thermal shock required for rapid pyrolysis. By allowing the sample to drop directly into a pre-heated zone, the reactor triggers a vigorous decomposition of precursors, creating a localized high-pressure environment that forces strong covalent bonding between MoS2 nanocrystals and Reduced Graphene Oxide (rGO).

Core Insight: The vertical configuration is not merely about orientation; it is a kinetic tool. It utilizes gravity to bypass slow heating ramps, using the rapid release of gases to physically and chemically fuse the composite materials together.

The Mechanics of Rapid Pyrolysis

Instantaneous Thermal Shock

In a vertical configuration, the sample can be introduced directly into the reactor's "hot zone" which is already preheated to the target temperature.

This eliminates the slow temperature ramp-up typical of horizontal furnaces.

The immediate exposure to high heat is essential for the specific chemical pathway required for high-quality MoS2/rGO synthesis.

Vigorous Precursor Decomposition

The sudden thermal shock triggers the vigorous decomposition of Ammonium Tetrathiomolybdate (ATM).

Because the heat transfer is immediate, the precursor breaks down rapidly rather than gradually.

This rapid reaction is the catalyst for the structural benefits discussed below.

Enhancing Structural Integrity

Generating Localized Pressure

The rapid decomposition of ATM releases a significant volume of gas in a fraction of a second.

This confined gas release generates a spike in local high pressure surrounding the sample.

This phenomenon is unique to the rapid heating profile allowed by the vertical drop method.

Promoting Covalent Bonding

The generated pressure serves a critical synthesis function: it forces the materials together at the atomic level.

This pressure promotes covalent bonding between the MoS2 nanocrystals and the graphene sheets.

Without this pressure-assisted bonding, the materials might simply physically adhere, resulting in lower structural stability and poorer electronic performance.

Ensuring Chemical Purity

Precise Atmosphere Control

The reactor design allows for the displacement of oxygen using high-purity argon gas.

This creates a strictly controlled environment, preventing the oxidation of the carbon lattice or the molybdenum.

Quartz Transparency and Inertness

The use of high-purity quartz provides a sealed, chemically inert vessel that isolates the process from external contaminants.

Additionally, the transparency of the quartz offers a functional benefit for research and monitoring.

It allows operators to visually observe the reaction state in real-time, ensuring the rapid decomposition occurs as intended.

Understanding the Trade-offs

While the vertical quartz reactor offers superior bonding for this specific composite, there are operational considerations to keep in mind.

Sample Size Limitations

Vertical tube reactors generally rely on gravity-fed mechanisms (like quartz boats or baskets), which often limits the batch size compared to horizontal rotary kilns.

Thermal Shock Risks

While the sample requires thermal shock, the quartz tube itself must be high-grade to withstand the temperature gradients.

Rapid insertion mechanisms must be designed carefully to avoid compromising the atmosphere seal or damaging the vessel.

Making the Right Choice for Your Goal

To determine if this reactor setup aligns with your specific synthesis targets, consider the following:

- If your primary focus is material performance: The vertical reactor is superior because the pressure-driven covalent bonding maximizes electron transfer between MoS2 and rGO.

- If your primary focus is process insight: The transparent quartz allows you to validate the decomposition timing and reaction vigorousness visually.

- If your primary focus is avoiding oxidation: The ability to purge with argon in a sealed vertical column ensures the high purity required for semiconductor-grade applications.

Ultimately, the vertical reactor transforms the synthesis from a passive heating process into a dynamic, pressure-assisted bonding event.

Summary Table:

| Feature | Functional Benefit for MoS2/rGO Synthesis |

|---|---|

| Vertical Gravity Feed | Enables instantaneous thermal shock by bypassing slow heating ramps. |

| Rapid Decomposition | Triggers vigorous ATM breakdown for immediate gas release. |

| Localized High Pressure | Forces strong covalent bonding between MoS2 nanocrystals and rGO sheets. |

| Quartz Vessel | Provides chemical inertness and visual monitoring of the reaction state. |

| Inert Atmosphere | Precise argon control prevents oxidation of carbon and molybdenum. |

Elevate Your Material Synthesis with KINTEK

Unlock the full potential of your MoS2/rGO research with precision-engineered thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory requirements.

Whether you need specialized vertical configurations for rapid pyrolysis or custom high-temperature furnaces for semiconductor-grade applications, our team is ready to assist. Contact us today to discuss your project requirements and see how our advanced heating technology can drive your next breakthrough.

Visual Guide

References

- Anna A. Vorfolomeeva, Lyubov G. Bulusheva. Molybdenum Disulfide and Reduced Graphene Oxide Hybrids as Anodes for Low-Temperature Lithium- and Sodium-Ion Batteries. DOI: 10.3390/nano15110824

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the core function of an industrial programmable tube furnace? Master Titania-Carbon Synthesis with Precision

- What are the different types of tubular furnaces? Choose the Right One for Your Lab

- What materials are required for high-temperature operation in tube furnaces? Choose the Right Tube for Your Lab

- What is the core function of a laboratory tube furnace in torrefaction? Optimize Fruit and Vegetable Waste Conversion

- What role do high-temperature tube or muffle furnaces play in biomass-derived carbon? Enhance Catalyst Performance

- What critical conditions does a high-temperature tube furnace provide for Ti–Nb–Si alloys? Master Sintering Success

- Why is the annealing process in a tube furnace under argon essential for NCMC heterostructures? Expert Insights

- Why Use a High-Precision Weighing System with a Tube Furnace for Magnetite Oxidation Kinetics? Achieve Real-Time Data.