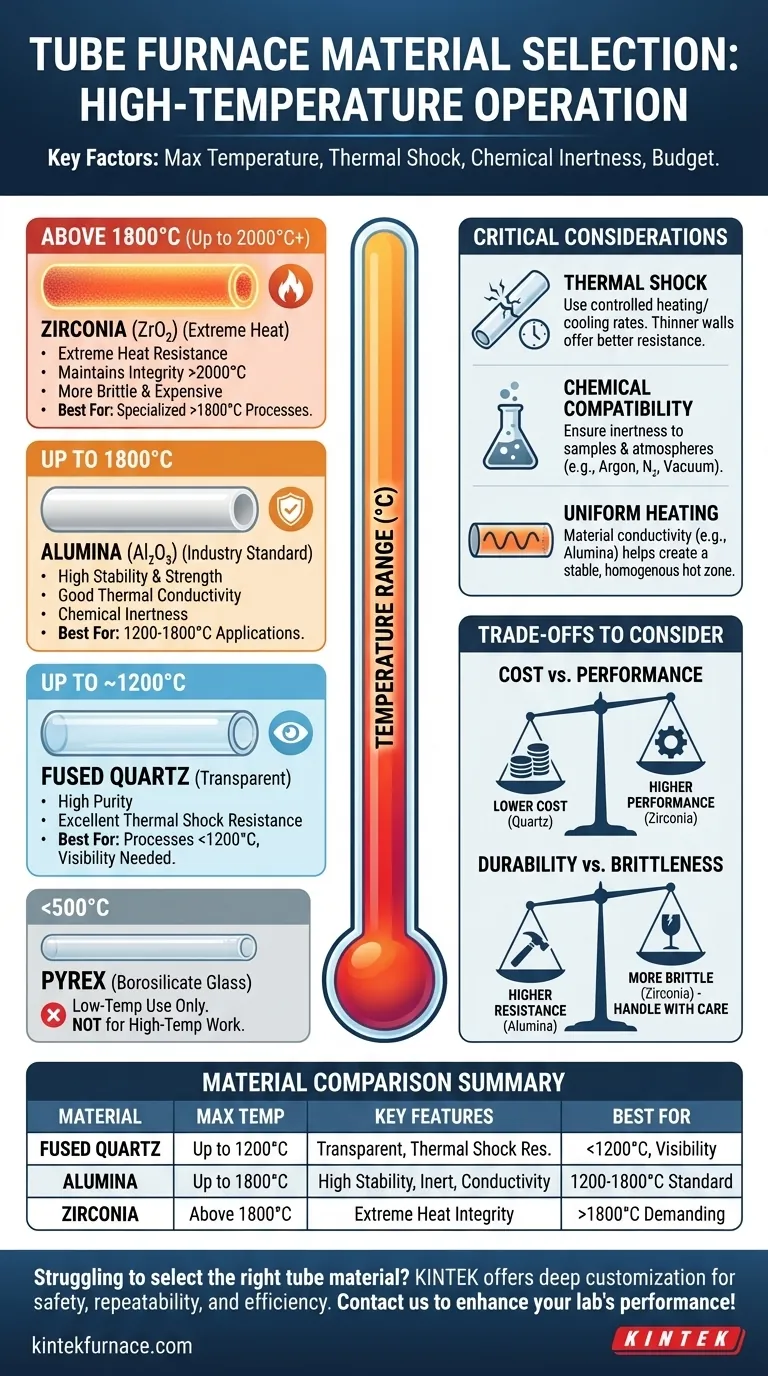

For high-temperature tube furnace operation, the required material is primarily dictated by your maximum operating temperature and process conditions. Alumina (Al₂O₃) is the industry standard for most high-temperature applications up to 1800°C (3272°F), while Zirconia (ZrO₂) is necessary for extreme conditions approaching 2000°C (3600°F). For more moderate temperatures, fused quartz is also a common and effective option.

The selection of a furnace tube is not simply about its melting point. It is a critical engineering decision that balances maximum temperature, resistance to thermal shock, chemical inertness, and budget. Choosing the wrong material can lead to equipment failure, sample contamination, and compromised results.

Matching the Material to the Temperature Range

The single most important factor in selecting a tube material is its maximum service temperature. Each material has a distinct operational ceiling that must be respected for safe and effective use.

Fused Quartz: The Transparent Choice (Up to ~1200°C)

Fused quartz tubes are an excellent choice for processes operating at or below 1100-1200°C. They offer high purity and excellent resistance to thermal shock, meaning they can withstand faster heating and cooling rates than most ceramics.

Their key advantage is optical transparency, allowing for direct visual observation of the process inside the furnace.

Alumina: The High-Temperature Workhorse (Up to 1800°C)

High-purity Alumina is the most common material for tube furnace applications ranging from 1200°C to 1800°C. It is chosen for its exceptional high-temperature stability and strength.

Alumina also possesses superior thermal conductivity compared to other ceramics, which helps ensure uniform heat distribution along the length of the tube—a critical factor for repeatable experiments and production.

Zirconia: For Extreme Heat (Above 1800°C)

When temperatures exceed the limits of Alumina, Zirconia becomes the required material. It maintains its structural integrity at temperatures of 2000°C and beyond.

Using Zirconia is a specialized application. It is significantly more expensive and often more brittle than Alumina, reserving its use for processes where extreme heat is non-negotiable.

Critical Factors Beyond Peak Temperature

A material's temperature rating is only the starting point. Successful operation depends on understanding how the material behaves under real-world process conditions.

Understanding Thermal Shock

All ceramic materials, including Alumina, are susceptible to thermal shock—failure caused by rapid temperature changes. While Alumina is considered resistant for a ceramic, it is not immune.

To prevent cracking, it is crucial to use programmed, controlled heating and cooling rates. Furthermore, tubes with smaller diameters and thinner walls have better resistance to thermal shock than larger, thicker tubes.

Chemical Compatibility and Atmosphere

The tube material must be chemically inert to your sample and any process gases at high temperatures. High-purity Alumina is highly stable and unreactive, making it suitable for use with inert atmospheres (like argon or nitrogen) or under vacuum.

Always verify that your specific process materials will not react with the furnace tube, as this can lead to contamination and tube degradation.

Uniform Heating and Construction

The goal of a tube furnace is to create a precise and uniform hot zone. The tube material is a key part of this system.

Materials like Alumina with good thermal conductivity help smooth out temperature variations from the heating elements, contributing to a more stable and homogenous processing environment.

Understanding the Trade-offs

Choosing the right tube involves balancing competing priorities. There is no single "best" material, only the most appropriate one for a specific task.

Cost vs. Performance

There is a direct correlation between temperature performance and cost. Fused quartz is the most affordable, Alumina represents a significant step up in both price and capability, and Zirconia is a premium material for the most demanding applications.

Durability vs. Brittleness

Higher temperature resistance often comes at the cost of increased brittleness. All ceramic tubes must be handled with care to avoid mechanical shock from being dropped or improperly clamped, which can cause immediate or future failure.

Pyrex: A Note on Low-Temperature Use

Pyrex (borosilicate glass) is sometimes mentioned alongside furnace tubes, but it is strictly a low-temperature material. Its use is limited to applications well below 500°C and it is not suitable for high-temperature work.

Making the Right Choice for Your Process

Your specific process goals will determine the ideal material. Use these guidelines to make a clear decision.

- If your primary focus is on processes below 1200°C and you value visibility: Fused quartz is your most practical and cost-effective choice.

- If your primary focus is on working between 1200°C and 1800°C: High-purity Alumina is the industry standard, offering the best balance of performance and reliability.

- If your primary focus is on applications that demand temperatures above 1800°C: You must invest in a specialized material like Zirconia, accepting its higher cost and stricter handling requirements.

Selecting the correct tube material is the foundational step to ensuring safe, repeatable, and successful high-temperature processing.

Summary Table:

| Material | Max Temperature | Key Features | Best For |

|---|---|---|---|

| Fused Quartz | Up to 1200°C | Transparent, high purity, excellent thermal shock resistance | Processes below 1200°C requiring visibility |

| Alumina | Up to 1800°C | High stability, good thermal conductivity, chemical inertness | Standard high-temperature applications (1200-1800°C) |

| Zirconia | Above 1800°C | Extreme heat resistance, structural integrity at 2000°C+ | Demanding processes exceeding 1800°C |

Struggling to select the right tube material for your high-temperature experiments? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor our products to precisely meet your unique experimental needs, ensuring safety, repeatability, and efficiency. Contact us today to discuss how our high-temperature furnace solutions can enhance your lab's performance!

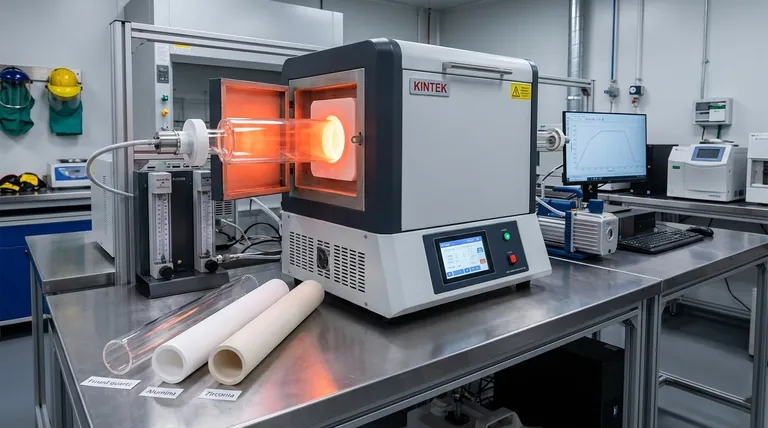

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the two primary types of tube furnaces and their main features? Compare Split vs. Solid Designs

- What is the purpose of thermal insulation in a tube furnace? Ensure Uniform Heating and Energy Efficiency

- What role does a high-vacuum tube furnace (CVD) play in HEA@CNT synthesis? Master Nanocomposite In-Situ Growth

- What is a three-zone tube furnace? Achieve Precise Thermal Control for Advanced Materials Processing

- How does tube furnace cracking compare to fuel furnaces in terms of efficiency? Discover Higher Efficiency and Precision

- Why is an industrial-grade tube furnace essential for reducing SrMo1−xMnxO4? Master SOFC Anode Synthesis

- What technical requirements affect the external thermal strength of furnace tubes? Optimize for High-Temp Performance

- What is the role of a Cyclone Collector in sample recovery in a DTF? Enhance Solid Residue Analysis Accuracy