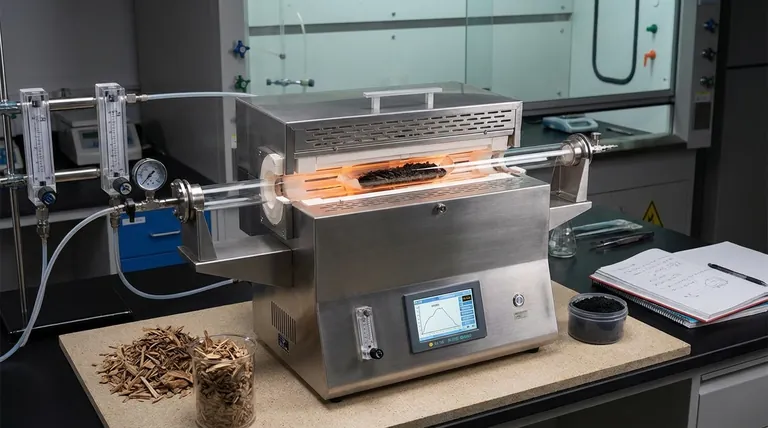

High-temperature tube and muffle furnaces serve as the critical reaction vessels that transform raw biomass into functional catalytic materials. They provide the strictly controlled thermal environment required to decompose organic matter, remove volatile components, and rearrange carbon atoms without burning the material into ash.

Core Takeaway The primary function of these furnaces is to facilitate the transition from complex organic biomass to a stable, graphitized carbon skeleton. By controlling temperature and atmosphere, they enable the creation of high electrical conductivity and the formation of active electrocatalytic centers, which are impossible to achieve under standard ambient conditions.

The Core Process: Pyrolysis and Carbonization

Thermal Decomposition

The fundamental role of these furnaces is to drive pyrolysis. By subjecting biomass to high temperatures (typically between 700°C and 900°C), the furnace forces the material to undergo dehydration and decarbonization.

Eliminating Volatiles

As the temperature rises, the furnace environment ensures the removal of volatile components. This leaves behind a rigid carbon structure rather than a tar-like residue.

Rearranging Atomic Structure

The heat induces the rearrangement of carbon atoms. This converts amorphous organic macromolecules into an ordered, graphitized carbon skeleton, which provides the electrical conductivity necessary for the material to function as an electrode or catalyst.

The Role of Atmosphere Control

Creating an Inert Environment

A critical differentiator for these furnaces, particularly tube furnaces, is the ability to maintain a specific atmosphere. They introduce inert gases like nitrogen or argon to exclude oxygen.

Preventing Combustion

Without this controlled atmosphere, high temperatures would simply burn the biomass. The oxygen-free environment ensures the material carbonizes (turns to charcoal) rather than combusts (turns to ash).

Facilitating Doping

The controlled atmosphere allows for precise chemical modifications. For example, maintaining a steady nitrogen flow allows for efficient nitrogen-doping from modifiers like urea, integrating foreign atoms into the carbon framework to enhance catalytic activity.

Surface Engineering and Activation

Etching Pore Structures

Beyond simple heating, these furnaces drive the kinetics required for activation. By maintaining precise temperatures (e.g., 600°C for activation), the furnace enables activators to react chemically with the carbon matrix, etching out a rich structure of micropores.

Oxidative Pre-treatment

While tube furnaces excel at inert processes, muffle furnaces are often utilized for oxidative pre-treatment. Heating supports to lower temperatures (e.g., 300°C) in air removes hydrophobic impurities and increases surface oxygen content.

Anchoring Active Sites

This surface modification creates "anchoring sites." These sites are essential for securing metal precursors (such as palladium or iron) to the carbon surface, ensuring uniform deposition and high catalytic performance.

Understanding the Trade-offs

Atmosphere Precision vs. Volume

Tube furnaces offer superior control over gas flow and atmosphere purity, making them ideal for strict pyrolysis and doping where oxygen exclusion is critical. However, they typically have smaller sample capacities.

Simplicity vs. Control

Muffle furnaces are generally better suited for batch processing, pre-sintering, or oxidative treatments where a strictly flowing inert gas is less critical. They are excellent for structural bonding (sintering) but may struggle to achieve the extreme atmospheric purity of a tube furnace for sensitive high-temperature carbonization.

Making the Right Choice for Your Goal

To maximize the quality of your biomass-derived carbon, select your equipment based on the specific stage of preparation:

- If your primary focus is Pyrolysis and Graphitization: Use a Tube Furnace to ensure a strictly inert nitrogen or argon atmosphere that prevents combustion and maximizes conductivity.

- If your primary focus is Surface Functionalization or Pre-treatment: Use a Muffle Furnace to perform oxidative heating (around 300°C) that creates anchoring sites for metal catalysts.

- If your primary focus is Doping (e.g., Nitrogen): Use a Tube Furnace with precise temperature ramps to facilitate the integration of dopants into the carbon lattice.

Success depends on using the furnace not just as a heater, but as a precision instrument to control the chemical evolution of your material.

Summary Table:

| Feature | Tube Furnace Role | Muffle Furnace Role |

|---|---|---|

| Primary Process | High-temp carbonization & nitrogen doping | Oxidative pre-treatment & batch sintering |

| Atmosphere | Strictly inert (Nitrogen/Argon/CVD) | Ambient air or static atmosphere |

| Key Outcome | Graphitized carbon skeleton & conductivity | Surface oxygen content & impurity removal |

| Best For | Oxygen-free pyrolysis & pore etching | Pre-heating & large volume structural bonding |

Elevate your materials science with precision thermal processing. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to your specific biomass carbonization and doping requirements. Ensure consistent graphitization and superior catalytic activity with our lab-grade furnaces. Contact KINTEK today to discuss your unique needs!

References

- Shuling Liu, Baojun Li. Catalytically Active Carbon for Oxygen Reduction Reaction in Energy Conversion: Recent Advances and Future Perspectives. DOI: 10.1002/advs.202308040

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety