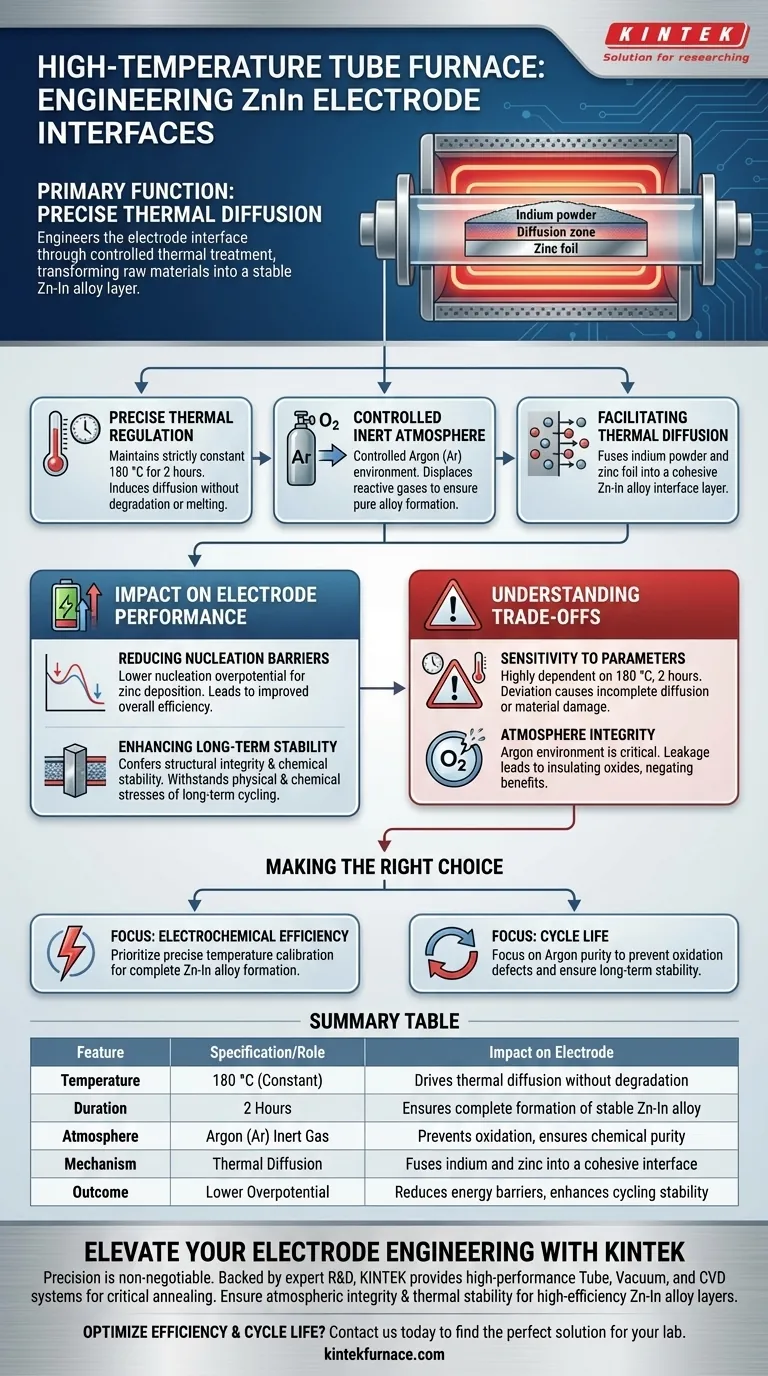

The primary function of a high-temperature tube furnace in this context is to engineer the electrode interface through precise thermal diffusion. Specifically, it maintains a controlled Argon (Ar) atmosphere at a constant 180 °C for two hours to facilitate the reaction between indium powder and zinc foil, resulting in a stable Zinc-Indium (Zn-In) alloy layer.

The furnace acts as a critical synthesis tool rather than a simple heater. It drives the diffusion process necessary to transform raw materials into a chemically stable alloy interface, which is the defining factor for the electrode's electrochemical efficiency and lifespan.

The Mechanics of Interface Engineering

Precise Thermal Regulation

The tube furnace must maintain a strictly constant temperature of 180 °C for a duration of 2 hours.

This specific thermal window is energetic enough to induce diffusion but controlled enough to prevent unwanted degradation or melting of the substrate components.

Controlled Inert Atmosphere

The process relies on a controlled Argon (Ar) environment.

By displacing reactive gases like oxygen, the furnace ensures that the thermal treatment results in pure alloy formation rather than surface oxidation, which would degrade performance.

Facilitating Thermal Diffusion

The core mechanism at work is thermal diffusion at the boundary between the indium powder and the zinc foil.

The furnace provides the energy required for atoms to migrate across this boundary, effectively fusing the two materials into a cohesive Zn-In alloy interface layer.

Impact on Electrode Performance

Reducing Nucleation Barriers

The engineered Zn-In alloy layer significantly reduces the nucleation overpotential required for zinc deposition.

This means the battery requires less energy to initiate the charging process, leading to improved overall efficiency.

Enhancing Long-Term Stability

The thermal treatment confers both structural integrity and chemical stability to the electrode.

By creating a robust alloy interface, the furnace ensures the electrode can withstand the physical and chemical stresses of long-term cycling without rapid degradation.

Understanding the Trade-offs

Sensitivity to Process Parameters

The effectiveness of this treatment is highly dependent on adhering to the specific time and temperature parameters (180 °C for 2 hours).

Deviating from these settings can lead to incomplete diffusion (if too low/short) or potential material damage (if too high/long), resulting in an unstable interface.

Atmosphere Integrity

The reliance on an Argon environment creates a point of failure regarding seal integrity.

Any leakage introducing oxygen during the high-temperature phase could lead to the formation of insulating oxides rather than the desired conductive alloy, negating the benefits of the annealing process.

Making the Right Choice for Your Goal

To maximize the effectiveness of the ZnIn electrode treatment, align your process controls with your specific performance targets:

- If your primary focus is Electrochemical Efficiency: Prioritize precise temperature calibration to ensure the Zn-In alloy forms completely, as this directly lowers the nucleation overpotential for zinc deposition.

- If your primary focus is Cycle Life: Focus on the purity of the Argon environment to prevent oxidation defects, ensuring the chemical stability required for long-term structural integrity.

The high-temperature tube furnace is the enabling technology that turns raw zinc and indium into a high-performance, durable electrode system.

Summary Table:

| Feature | Specification/Role | Impact on Electrode |

|---|---|---|

| Temperature | 180 °C (Constant) | Drives thermal diffusion without material degradation |

| Duration | 2 Hours | Ensures complete formation of stable Zn-In alloy layer |

| Atmosphere | Argon (Ar) Inert Gas | Prevents oxidation and ensures chemical purity |

| Mechanism | Thermal Diffusion | Fuses indium powder and zinc foil into a cohesive interface |

| Outcome | Lower Overpotential | Reduces energy barriers and enhances cycling stability |

Elevate Your Electrode Engineering with KINTEK

Precision is non-negotiable when engineering the next generation of battery interfaces. Backed by expert R&D and world-class manufacturing, KINTEK provides the high-performance Tube, Vacuum, and CVD systems required for critical annealing processes. Our customizable high-temperature furnaces ensure the atmospheric integrity and thermal stability necessary to produce high-efficiency Zn-In alloy layers.

Ready to optimize your electrochemical efficiency and cycle life? Contact us today to find the perfect solution for your lab.

Visual Guide

References

- Tian Wang, Jae Su Yu. Surface Patterning of Metal Zinc Electrode with an In-Region Zincophilic Interface for High-Rate and Long-Cycle-Life Zinc Metal Anode. DOI: 10.1007/s40820-024-01327-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of insulation in a 70mm tube furnace? Ensure Precision and Efficiency in Your Lab

- What is the primary function of a dual-zone tube furnace in CVT? Precision Gradients for FexTaSe2 Crystal Growth

- Why is it necessary to precisely control the oxygen flow rate in a tube furnace? Optimize Li-Deficient Composites

- What is the significance of using a tubular furnace in waste salt pyrolysis research? Precision for High-Fidelity Data

- What is the difference between a vacuum tube furnace and a standard tube furnace? Choose the Right Furnace for Your Lab

- Why is precise temperature control in muffle or tube furnaces critical for Fe3GaTe2 crystal growth? Expert Insights

- How does a high-temperature tube furnace combustion system function in food waste analysis? Master Ultimate Analysis

- What is the purpose of flushing a tube furnace with high-purity argon for hours? Ensure Pure Silicon Steel Results