The high-temperature tube furnace combustion system functions by isolating food waste samples within a sealed environment and subjecting them to uniform, intense thermal energy. This process ensures the complete combustion of complex organic matter, converting solid waste into a stream of detectable exhaust gases. By analyzing these gases, researchers can determine the precise concentrations of carbon, hydrogen, nitrogen, and sulfur required for accurate ultimate analysis.

The core takeaway is that the tube furnace acts as a precision reactor that transforms heterogeneous food waste into a homogenous gas stream, providing the essential elemental data needed for carbon balance calculations and pyrolysis modeling.

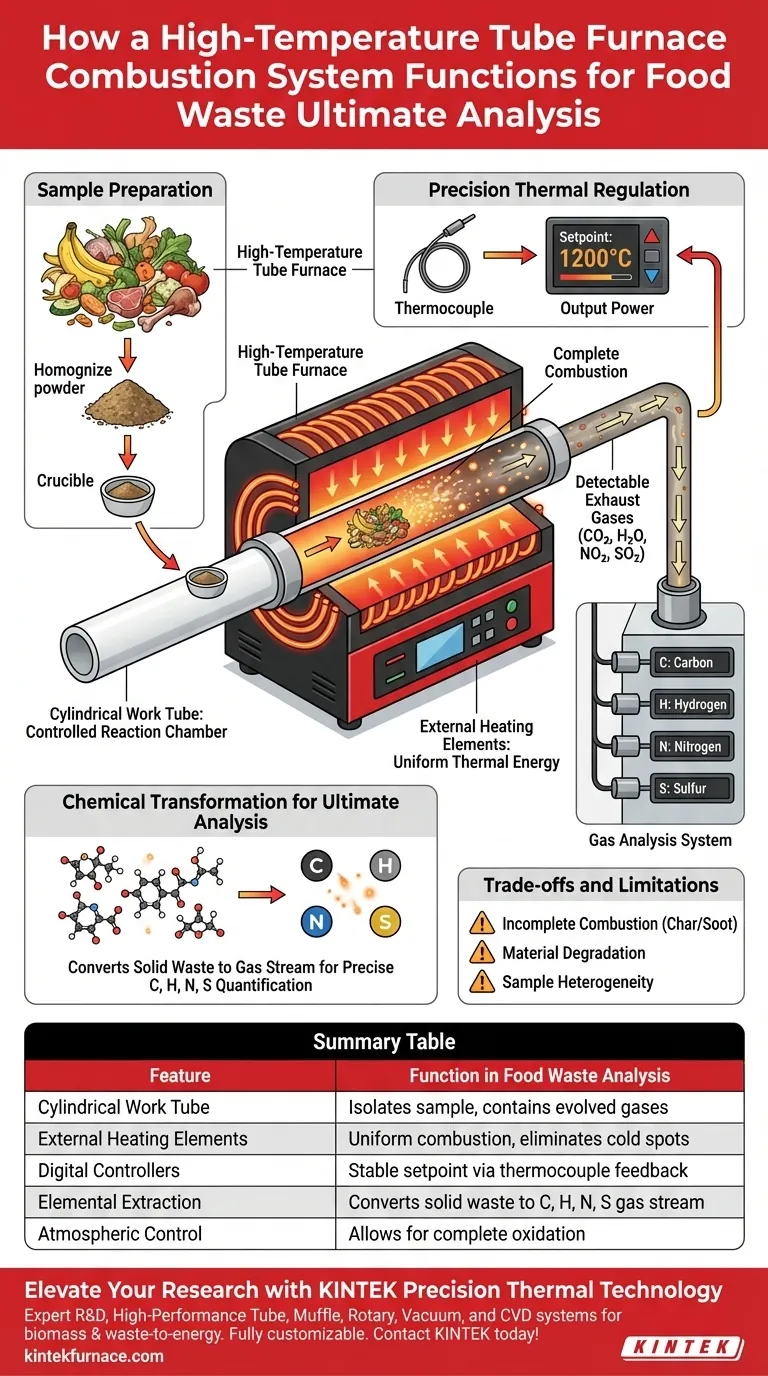

The Mechanical Architecture of the Combustion System

The Role of the Cylindrical Work Tube

The heart of the system is a cylindrical work tube where the food waste mixture is placed. This tube serves as a controlled reaction chamber, isolating the sample from external contaminants while containing the evolved gases for analysis.

External Heating Elements

Heating elements are strategically located outside the work tube, surrounding it to provide uniform heat along its entire length. This design ensures that the sample experiences a consistent temperature gradient, which is critical for achieving reproducible results in ultimate analysis.

Sample Loading and Containment

Samples are loaded into the tube before it is installed in the furnace and sealed. This containment allows for the precise manipulation of the internal atmosphere, ensuring that the combustion process occurs under specific, user-defined conditions.

Precision Thermal Regulation and Monitoring

Feedback via Thermocouple Sensors

The system utilizes thermocouples or temperature sensors to continuously monitor the internal thermal environment. These sensors provide real-time data to the system's controller, ensuring the furnace maintains the high temperatures required for complete elemental breakdown.

Digital Control Systems

A digital controller receives signals from the sensors and automatically adjusts the power output of the heating elements. This closed-loop system allows the user to set specific parameters, ensuring the furnace reaches and maintains the exact temperature setpoint needed for the food waste mixture.

Achieving Uniform Temperature Distribution

Because the heating elements surround the tube, the system achieves an even temperature distribution. This uniformity prevents "cold spots" that could lead to the incomplete combustion of the food waste, which would otherwise skew the final elemental data.

Chemical Transformation for Ultimate Analysis

Complete Combustion of Complex Waste

The primary function during ultimate analysis is to facilitate complete combustion. The high-temperature environment breaks down the complex chemical bonds in food waste, converting the solid matrix into its constituent elements in gaseous form.

Extraction of Elemental Data

The process specifically targets the determination of sulfur, carbon, hydrogen, and nitrogen content. These measurements serve as the baseline data for subsequent calculations, such as determining the pyrolysis carbon balance.

Creating a Gas Stream for Detection

As the sample combusts, it produces a stream of detectable exhaust gases. These gases are then analyzed to quantify the exact mass fraction of each element present in the original food waste mixture.

Understanding the Trade-offs and Limitations

The Risk of Incomplete Combustion

If the furnace temperature is not sufficiently high or the residence time is too short, the food waste may not fully oxidize. Incomplete combustion leads to the formation of char or soot, which traps carbon and sulfur, resulting in an underestimation of the sample's true elemental composition.

Material Degradation and Contamination

Operating at the high temperatures required for ultimate analysis can cause the work tube to degrade over time. This degradation can introduce impurities into the gas stream or lead to leaks, compromising the integrity of the atmospheric control and the accuracy of the sulfur measurements.

Sensitivity to Sample Heterogeneity

Food waste is notoriously non-uniform, and small sample sizes used in tube furnaces may not always be representative of the bulk material. This requires meticulous sample preparation and homogenization to ensure that the ultimate analysis reflects the true nature of the waste mixture.

How to Apply This to Your Project

When utilizing a high-temperature tube furnace for the ultimate analysis of food waste, your approach should vary based on your specific research goals.

- If your primary focus is sulfur quantification: Ensure the furnace is calibrated to the specific high-temperature range required to fully evolve sulfur dioxide without loss to the furnace walls.

- If your primary focus is pyrolysis carbon balance: Focus on the precision of the temperature control system to ensure every milligram of carbon is accounted for in the gaseous phase.

- If your primary focus is equipment longevity: Implement a gradual heating and cooling ramp in your digital controller to minimize thermal shock to the ceramic work tube.

By mastering the thermal and chemical dynamics of the tube furnace, you can transform volatile food waste into the high-fidelity data required for advanced bioenergy modeling.

Summary Table:

| Feature | Function in Food Waste Analysis |

|---|---|

| Cylindrical Work Tube | Isolates sample and contains evolved gases for elemental detection. |

| External Heating Elements | Surrounds the tube to ensure uniform combustion and eliminate cold spots. |

| Digital Controllers | Regulates power output via thermocouples for stable setpoint maintenance. |

| Elemental Extraction | Converts solid waste into a gas stream to quantify C, H, N, and S. |

| Atmospheric Control | Allows for specific oxygen or inert environments for complete oxidation. |

Elevate Your Research with Precision Thermal Technology

Maximize the accuracy of your ultimate analysis and pyrolysis modeling with KINTEK. Backed by expert R&D and world-class manufacturing, we provide high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for complex applications like biomass and waste-to-energy research.

Whether you need custom dimensions or specific atmospheric controls, our lab high-temp furnaces are fully customizable to meet your unique needs. Contact KINTEK today to discuss your laboratory requirements and see how our expertise can streamline your data collection.

Visual Guide

References

- Zsolt Dobó, Gábor Nagy. Production of Biochar by Pyrolysis of Food Waste Blends for Negative Carbon Dioxide Emission. DOI: 10.3390/en18010144

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the different types of tube furnaces and their specific uses? Find Your Ideal Lab Solution

- How does a high-temperature tube furnace contribute to the preparation of highly porous carbon sheets from cellulose?

- What are some common applications of horizontal electric furnaces? Unlock Precision in Thermal Processing

- What is the function of a high-temperature tube furnace in ZIF-8 carbonization? Achieve High-Performance NC Supports

- What core functions does a high-temperature tube furnace provide? Master TiN-Carbon Composite Pyrolysis

- What is the function of a tube reduction furnace? Enhance Ru@PG Catalysts with Ar/H2 Precision

- What is the technical value of using an industrial-grade tube furnace for titania nanotubes? Enhance Crystal Performance

- Why is a tube furnace with precise temperature control required for CuSbSe2 thin films? Achieve High Phase Purity