At their core, tube furnaces are categorized by their physical orientation (horizontal, vertical, or rotary) and their operational capabilities, such as maximum temperature and atmosphere control. These factors directly determine their use, with horizontal furnaces serving as general-purpose tools, vertical furnaces excelling in processes like Chemical Vapor Deposition (CVD), and specialized furnaces handling high temperatures, vacuum, or specific materials like graphite.

The most effective way to select a tube furnace is not by memorizing a list of types, but by matching the furnace's core attributes—orientation, temperature, and atmosphere—to the precise requirements of your scientific process or industrial application.

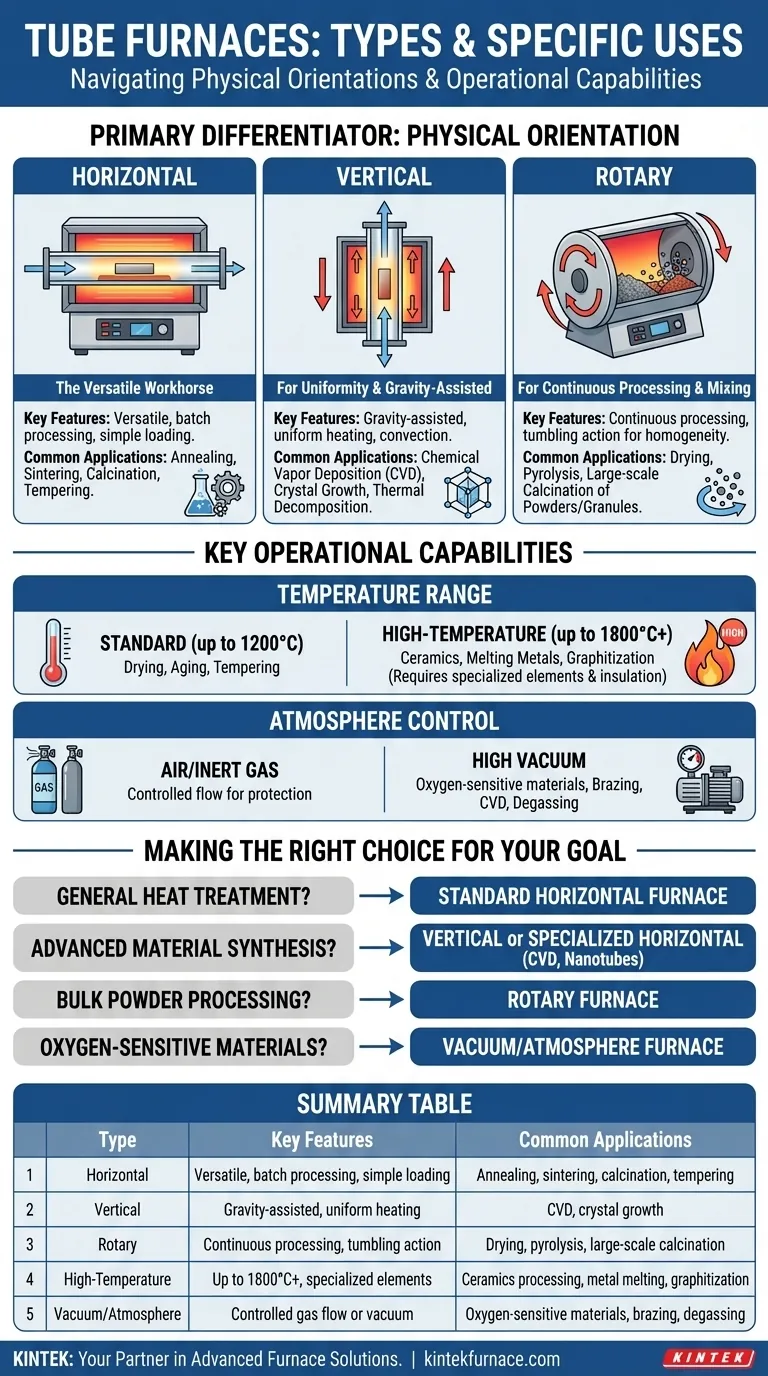

The Primary Differentiator: Physical Orientation

The physical layout of the furnace is the first and most fundamental design choice. It dictates how your sample is held, heated, and processed, making it the primary factor in matching a furnace to an application.

Horizontal Tube Furnaces: The Versatile Workhorse

Horizontal furnaces are the most common type due to their simplicity and versatility. The sample is placed in a process tube and loaded horizontally into the heated chamber.

This configuration is ideal for general-purpose heat treatments like annealing, sintering, calcination, and tempering, where samples can rest on a flat surface. They are excellent for batch processing a wide variety of materials.

Vertical Tube Furnaces: For Uniformity and Gravity-Assisted Processes

In a vertical furnace, the process tube is oriented upright. This design allows gravity to assist in certain processes and can improve temperature uniformity through natural convection.

They are the preferred choice for applications like Chemical Vapor Deposition (CVD), crystal growth, and thermal decomposition, where precursors can be dropped or flowed over a substrate.

Rotary Tube Furnaces: For Continuous Processing and Mixing

Rotary tube furnaces feature a process tube that rotates slowly, tumbling the material inside. This ensures every particle is exposed to the same heat and atmosphere.

This makes them exceptionally well-suited for the continuous processing of powders, granules, and other bulk materials. Common uses include drying, pyrolysis, and large-scale calcination where homogeneity is critical.

Key Operational Capabilities

Beyond orientation, the furnace's ability to achieve specific temperatures and control its internal atmosphere defines its true utility.

Temperature Range: Standard vs. High-Temperature

Standard tube furnaces typically operate up to 1200°C. They are used for a vast range of applications, including drying, aging, and tempering.

High-temperature furnaces can reach 1500°C, 1800°C, or even higher. These require specialized heating elements (like MoSi2 or Tungsten) and advanced insulation, making them essential for processing ceramics, melting metals, and graphitization.

Atmosphere Control: From Air to High Vacuum

The ability to control the atmosphere inside the process tube is critical for many advanced applications. Furnaces can be designed to operate in air, with a controlled flow of inert gas (like Argon or Nitrogen), or under vacuum.

Vacuum and controlled-atmosphere furnaces are non-negotiable for working with oxygen-sensitive materials, preventing oxidation during brazing or annealing, and for processes like CVD and degassing.

Understanding the Trade-offs

Selecting a tube furnace involves balancing performance with practical constraints. Understanding these trade-offs is key to making a sound investment.

Cost vs. Capability

There is a direct and significant cost increase associated with higher temperature ratings and vacuum capabilities. A high-temperature, high-vacuum furnace is a far more complex and expensive instrument than a standard air atmosphere furnace.

Uniformity vs. Throughput

A static horizontal furnace can provide exceptional temperature uniformity over a specific "hot zone," which is ideal for precise research. A rotary furnace offers much higher throughput for powders but may have slight temperature variations as the material tumbles.

Material Compatibility and the Process Tube

The furnace itself is only half the equation. The process tube material (e.g., quartz, alumina, silicon carbide) must be chosen carefully. Quartz is cost-effective but has a lower temperature limit (~1100°C), while high-purity alumina or silicon carbide tubes are required for higher temperatures and can better withstand thermal shock.

Making the Right Choice for Your Goal

Your final decision should be guided by the primary goal of your work.

- If your primary focus is general heat treatment (annealing, sintering): A standard horizontal tube furnace offers the best balance of versatility and cost.

- If your primary focus is advanced material synthesis (CVD, nanotubes): A vertical or specialized horizontal furnace with precise gas flow and temperature control is necessary.

- If your primary focus is bulk powder processing (calcination): A rotary tube furnace is the most efficient choice for ensuring homogenous treatment.

- If your primary focus is working with oxygen-sensitive materials: A furnace with vacuum capability or inert gas flow control is a mandatory requirement.

By aligning the furnace's fundamental design with your application's needs, you can confidently select the right tool for the job.

Summary Table:

| Type | Key Features | Common Applications |

|---|---|---|

| Horizontal | Versatile, batch processing, simple loading | Annealing, sintering, calcination, tempering |

| Vertical | Gravity-assisted, uniform heating | Chemical Vapor Deposition (CVD), crystal growth |

| Rotary | Continuous processing, tumbling action | Drying, pyrolysis, large-scale calcination |

| High-Temperature | Up to 1800°C+, specialized elements | Ceramics processing, metal melting, graphitization |

| Vacuum/Atmosphere | Controlled gas flow or vacuum | Oxygen-sensitive materials, brazing, degassing |

Struggling to choose the right tube furnace for your lab? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs—ensuring optimal performance for applications like annealing, CVD, and powder processing. Contact us today to discuss how we can enhance your laboratory efficiency and results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control