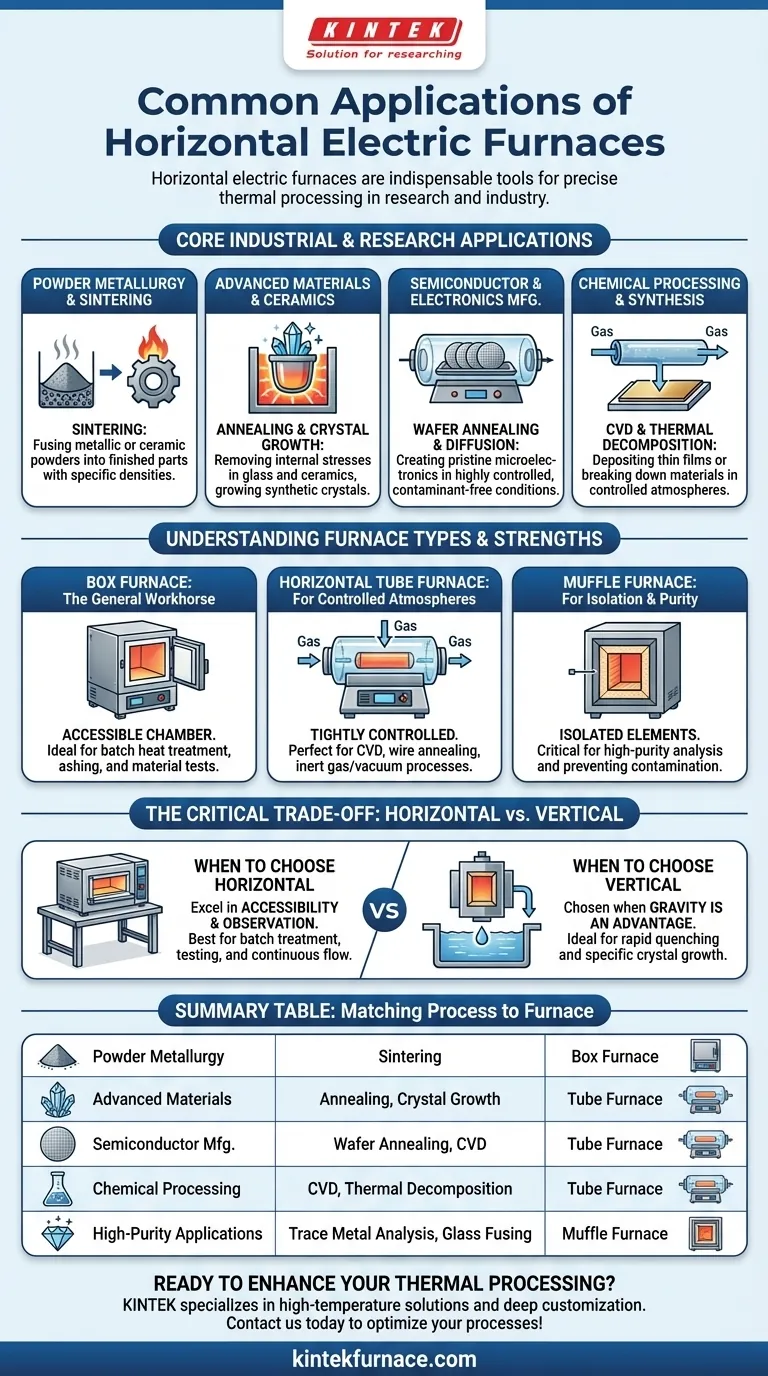

In short, horizontal electric furnaces are indispensable tools for a wide range of thermal processing applications across research and industry. Their primary uses include powder metallurgy and sintering, advanced materials research, heat treatment of metals and ceramics, and semiconductor manufacturing, where precise temperature and atmospheric control are critical.

The versatility of a horizontal electric furnace comes from its accessible design and stable processing environment. Understanding the subtle differences between its main types—box, tube, and muffle—is the key to selecting the right tool for a specific scientific or industrial goal.

Core Industrial & Research Applications

The horizontal configuration is the default for many thermal processes due to its ease of use and adaptability. Its applications are defined by the need for controlled, high-temperature environments.

Powder Metallurgy and Sintering

Sintering is the process of compacting and forming a solid mass of material by heat, without melting it to the point of liquefaction.

Horizontal furnaces provide the uniform, stable heating zones necessary to fuse metallic or ceramic powders into finished parts with specific densities and mechanical properties.

Advanced Materials and Ceramics

Developing new materials requires exceptionally precise thermal cycles. Horizontal furnaces are used for annealing glass to remove internal stresses, firing advanced ceramics, and growing synthetic crystals.

The ability to accurately program temperature ramps and soaks is essential for achieving the desired crystalline structure or material phase.

Semiconductor and Electronics Manufacturing

The production of microelectronics relies on pristine, highly controlled processing conditions.

Horizontal tube furnaces are used for critical steps like annealing silicon wafers, diffusing dopants into a substrate, and oxidizing surfaces to create insulating layers. The sealed tube environment prevents contamination.

Chemical Processing and Synthesis

Many chemical reactions are activated by heat. Horizontal tube furnaces are ideal for processes like Chemical Vapor Deposition (CVD), where precursor gases flow through the hot zone to deposit a thin film onto a substrate.

They are also used for thermal decomposition, where a material is heated in a controlled atmosphere to break it down into its constituent parts.

Understanding the Furnace Types and Their Strengths

While "horizontal electric furnace" is a broad category, the specific design dictates its ideal use case. The three most common types are box, tube, and muffle furnaces.

The Box Furnace: The General Workhorse

A box furnace is exactly what it sounds like: a chamber with a front-opening door. It is the most common type for general-purpose heat treatment.

Its accessible chamber is ideal for processing batches of small parts, conducting material tests, or performing ashing and elemental analysis on samples.

The Horizontal Tube Furnace: For Controlled Atmospheres

A tube furnace uses a ceramic or quartz tube that runs horizontally through the heating elements. The ends of the tube can be sealed, allowing for a tightly controlled atmosphere (e.g., inert gas, vacuum).

This design is perfect for processes like CVD, annealing wires or rods, and any application where samples need to be isolated from the open air or observed during processing.

The Muffle Furnace: For Isolation and Purity

A muffle furnace is a specialized design where the heating elements are physically separated from the processing chamber by a "muffle," or an inner lining.

This isolation prevents any potential contamination from the heating elements, which is critical for high-purity applications like trace metal analysis, glass fusing, and brazing sensitive alloys.

The Critical Trade-off: Horizontal vs. Vertical Furnaces

The choice between a horizontal and vertical orientation is not arbitrary; it is driven entirely by the process requirements.

When to Choose Horizontal

The horizontal orientation excels in accessibility and observation. Loading samples is straightforward, and the setup is ideal for processes that benefit from a continuous flow, like in a tube furnace.

It is the default choice for most batch heat treatments, laboratory testing, and chemical synthesis applications.

When to Choose Vertical

A vertical furnace is chosen when gravity is an advantage. The classic example is rapid quenching, where a sample is heated and then dropped from the hot zone into a liquid bath below.

This orientation is also beneficial for certain crystal growth methods or when you want to minimize contact between the sample and the furnace tube walls.

Making the Right Choice for Your Process

Your specific goal dictates the ideal furnace configuration. The key is to match the furnace's strengths to your process needs.

- If your primary focus is batch processing or general heat treatment: A horizontal box furnace offers the best combination of capacity and ease of use.

- If your primary focus is controlled atmosphere reactions or continuous processing: A horizontal tube furnace provides the necessary environmental control and flow-through capability.

- If your primary focus is high-purity analysis or preventing sample contamination: A muffle furnace design delivers the essential isolation from heating elements.

- If your primary focus is rapid quenching or specific gravity-fed applications: A vertical furnace is purpose-built for these tasks and will outperform a horizontal model.

Ultimately, selecting the correct furnace is about understanding how its physical design enables the precise thermal and atmospheric conditions your work demands.

Summary Table:

| Application Area | Key Processes | Ideal Furnace Type |

|---|---|---|

| Powder Metallurgy | Sintering | Box Furnace |

| Advanced Materials | Annealing, Crystal Growth | Tube Furnace |

| Semiconductor Manufacturing | Wafer Annealing, CVD | Tube Furnace |

| Chemical Processing | CVD, Thermal Decomposition | Tube Furnace |

| High-Purity Applications | Trace Metal Analysis, Glass Fusing | Muffle Furnace |

Ready to enhance your thermal processing with precision? KINTEK specializes in high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our advanced furnaces can optimize your research or industrial processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency