The core advantages of a tube furnace are its exceptional control over the processing environment, specifically temperature and atmosphere. This precision, combined with a versatile and efficient design, makes it an indispensable tool for both advanced laboratory research and specialized industrial production.

The true value of a tube furnace is not just its heating capability, but its power to create a highly isolated and stable environment. This level of control is what enables reproducible scientific data, the synthesis of high-purity materials, and efficient, high-yield manufacturing processes.

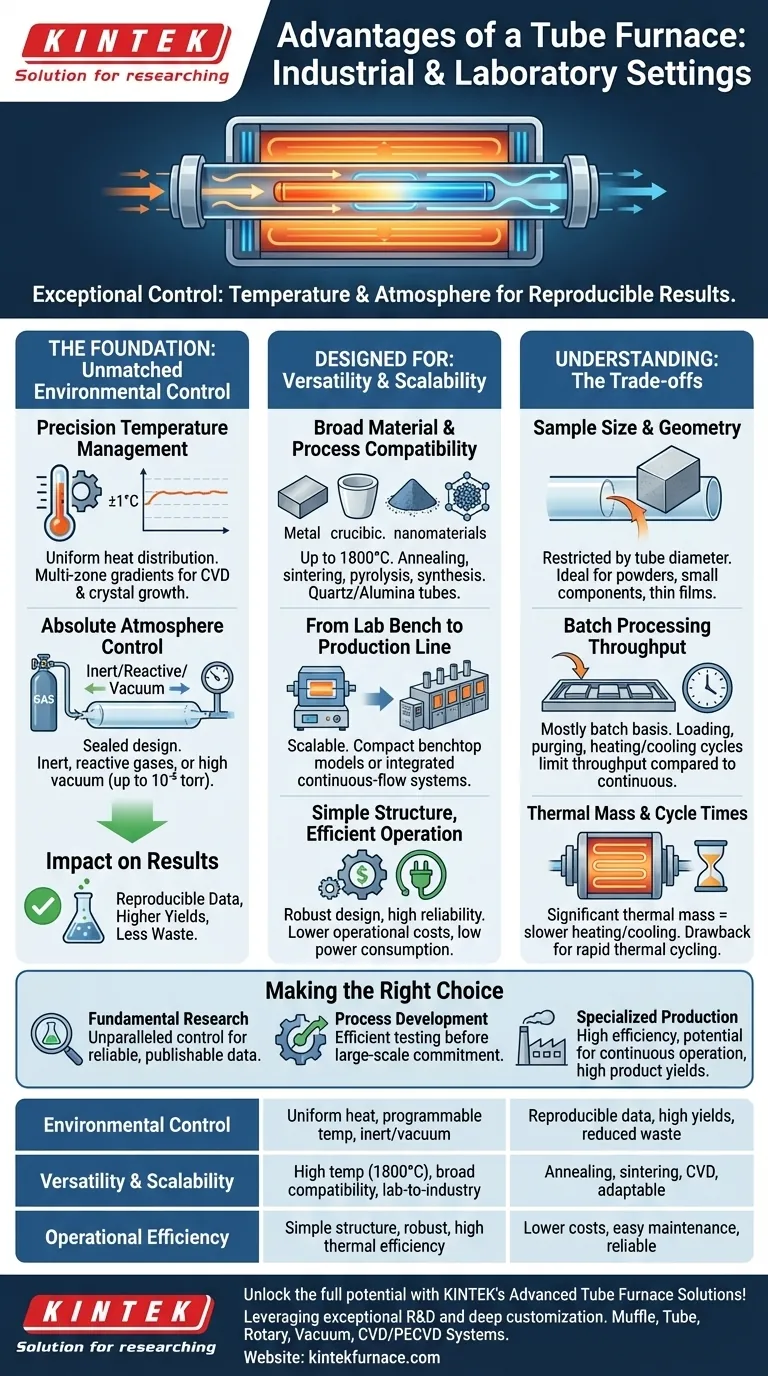

The Foundation: Unmatched Environmental Control

A tube furnace's primary strength is its ability to eliminate variables. Its enclosed, cylindrical design is engineered for consistency, which is the bedrock of reliable outcomes.

Precision Temperature Management

A tube furnace provides exceptionally uniform heat distribution along the length of the processing tube. This prevents hot or cold spots that can ruin sensitive materials or experiments.

Modern furnaces offer programmable controls with stability often within ±1°C of the setpoint. Multi-zone configurations allow for creating specific temperature gradients, a critical feature for processes like chemical vapor deposition (CVD) and crystal growth.

Absolute Atmosphere Control

The sealed tube design is ideal for managing the gaseous environment. You can easily purge the air and introduce a specific atmosphere, a capability that is difficult to achieve in other furnace types.

This includes processing under inert gas (like argon or nitrogen) to prevent oxidation, using reactive gases for specific chemical processes, or creating a high-level vacuum (down to 10⁻⁵ torr) for purification or deposition tasks.

The Impact on Results

This tight control directly translates to better outcomes. For researchers, it means reproducible and reliable data. For manufacturers, it means higher process yields, greater product purity, and less material waste.

Designed for Versatility and Scalability

Beyond environmental control, the physical design of a tube furnace offers significant practical benefits for a wide range of applications.

Broad Material & Process Compatibility

Tube furnaces can accommodate a vast array of materials, including metals, ceramics, polymers, and advanced nanomaterials.

Their ability to reach high temperatures (up to 1800°C) and control the atmosphere makes them suitable for diverse processes like annealing, sintering, calcination, pyrolysis, and material synthesis. The choice of tube material, such as quartz or alumina, further expands chemical and thermal compatibility.

From Lab Bench to Production Line

Tube furnaces are inherently scalable. Compact, space-saving models are perfect for laboratory benchtops where space is at a premium.

For industrial needs, multiple furnaces can be integrated for larger-scale production, or specialized continuous-flow models can be used to move from batch processing to a more efficient workflow.

Simple Structure, Efficient Operation

The underlying technology is mature, resulting in a simple and robust structure. This leads to high reliability and ease of maintenance.

Combined with high thermal efficiency and relatively low power consumption, the operational costs are often lower than those of larger, more complex furnace systems.

Understanding the Trade-offs

No single tool is perfect for every job. To make an informed decision, it's critical to understand the inherent limitations of a tube furnace.

Sample Size and Geometry Constraints

The most obvious limitation is the diameter of the tube. This restricts the size and shape of the samples you can process. It is ideal for powders, small components, or thin films on substrates but unsuitable for large, bulky objects.

Batch Processing Throughput

While continuous models exist, the majority of lab-scale tube furnaces operate on a batch basis. The time required to load, purge, heat, cool, and unload can limit overall throughput compared to true continuous industrial ovens.

Thermal Mass and Cycle Times

The ceramic insulation required for high-temperature stability gives the furnace significant thermal mass. This means that heating and cooling cycles can be slow, which may be a drawback for applications requiring rapid thermal cycling.

Making the Right Choice for Your Application

To determine if a tube furnace is the right fit, consider your primary objective.

- If your primary focus is fundamental research or material synthesis: The unparalleled temperature and atmosphere control are essential for producing reliable, publishable data and high-purity materials.

- If your primary focus is process development and pilot-scale testing: The furnace's versatility allows you to test various materials and processes efficiently before committing to larger, more expensive industrial equipment.

- If your primary focus is specialized industrial production: The high efficiency, potential for continuous operation, and high product yields make it an excellent choice for targeted applications like fiber drawing or component annealing.

Ultimately, selecting a tube furnace is a decision for precision, granting you exceptional control over the critical variables that define your success.

Summary Table:

| Advantage | Key Features | Benefits |

|---|---|---|

| Environmental Control | Uniform heating, programmable temperature (±1°C), inert/reactive gas handling, vacuum capability | Reproducible data, high process yields, reduced material waste |

| Versatility & Scalability | High temperatures (up to 1800°C), broad material compatibility, scalable from lab to industrial use | Suitable for annealing, sintering, CVD, and more, adaptable to various applications |

| Operational Efficiency | Simple structure, robust design, high thermal efficiency, low power consumption | Lower operational costs, ease of maintenance, reliable performance |

Unlock the full potential of your laboratory or industrial processes with KINTEK's advanced tube furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior results. Contact us today to discuss how our tailored solutions can enhance your efficiency and outcomes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing