At its core, the sealing condition in a vacuum tube experimental furnace is achieved using a precisely engineered stainless steel sealing flange system. This system is designed to create an airtight seal at the ends of the quartz or corundum tube that contains the experiment, allowing you to either remove the ambient air to create a vacuum or introduce a specific, controlled gas atmosphere.

The challenge isn't just sealing the tube, but creating a controllable environment. The stainless steel flange is the critical interface that transforms a simple furnace tube into a sealed vessel, giving you complete control over the atmosphere for your experiment.

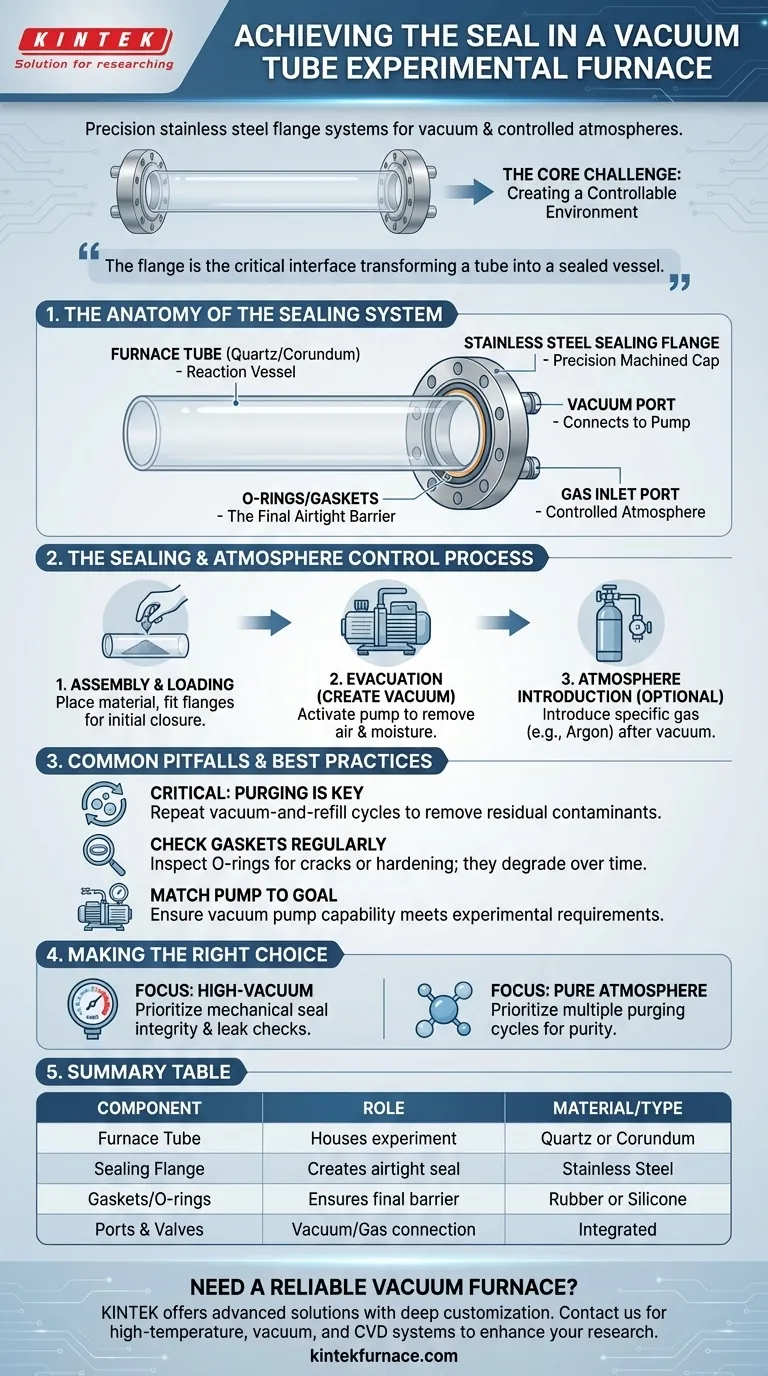

The Anatomy of the Sealing System

To understand how the seal is achieved, you must first understand the key components that work together. The system is simple by design but relies on precision for its effectiveness.

The Furnace Tube: Your Reaction Vessel

The primary container for your experiment is a tube, typically made of quartz or corundum (a type of high-purity alumina). These materials are chosen for their ability to withstand extreme temperatures and rapid temperature changes (thermal shock) without cracking.

The Stainless Steel Sealing Flange

This is the most critical component for achieving a seal. It is a precisely machined cap that fits over the open end of the furnace tube. Its design ensures a tight, secure closure that can withstand the pressure difference created by a vacuum.

Integrated Ports and Valves

The flange is not just a solid cap. It includes one or more ports equipped with valves. One port is designated for connecting a vacuum pump, while another serves as an air inlet for introducing a specific experimental atmosphere (e.g., argon, nitrogen).

The Sealing and Atmosphere Control Process

Achieving a proper seal involves a clear, methodical procedure. Following these steps ensures the integrity of your experimental environment.

Step 1: Material Loading and Assembly

First, the experimental material is placed inside the quartz or corundum tube. The stainless steel sealing flanges are then carefully fitted onto both ends of the tube to create the initial closure.

Step 2: Evacuation (Creating the Vacuum)

A vacuum pump is connected to the designated port on the flange. The pump is activated to extract all the ambient air and moisture from inside the tube, reducing the internal pressure and creating a vacuum.

Step 3: Atmosphere Introduction (Optional)

If the experiment requires a specific gas environment rather than a vacuum, that gas is introduced through the reserved air inlet on the flange after the initial vacuum has been pulled. This ensures the internal atmosphere is composed purely of the desired gas.

Common Pitfalls and Best Practices

A perfect seal is crucial for reproducible results. Simply assembling the components is often not enough; technique matters.

The Critical Importance of Purging

For experiments requiring a high-purity atmosphere, it is not enough to simply pump out the air once and introduce your gas. Residual atmospheric gases will remain.

The best practice is to purge the system. This involves first pumping the tube down to a vacuum, then back-filling it with the desired atmosphere. Repeating this cycle several times effectively dilutes and removes any remaining contaminants like oxygen or water vapor.

Seal Integrity Depends on Gaskets

The seal is not just metal-on-glass. Flange systems rely on O-rings or gaskets to create the final airtight barrier. These components can degrade over time with heat and use. Always inspect them for cracks or hardening before an experiment, as a faulty O-ring is a common point of failure.

Matching the Pump to the Goal

The level of vacuum you can achieve is determined by your vacuum pump, not just the furnace. Ensure your pump is capable of reaching the vacuum pressure your experiment requires. A leak in the flange system will prevent even the best pump from reaching its target vacuum.

Making the Right Choice for Your Goal

Your experimental objective dictates where you should focus your attention during the setup process.

- If your primary focus is a high-vacuum experiment: Your priority is the mechanical integrity of the seal. Double-check all flange connections, O-rings, and valve seals for leaks.

- If your primary focus is a pure, controlled atmosphere: Your priority is the purging process. Repeat the vacuum-and-refill cycle multiple times to ensure the highest possible purity of your chosen gas.

Understanding that the flange system is your gateway to controlling the internal environment is the first step toward successful and repeatable experiments.

Summary Table:

| Component | Role in Sealing | Material/Type |

|---|---|---|

| Furnace Tube | Houses experiment, withstands high temperatures | Quartz or Corundum |

| Sealing Flange | Creates airtight seal with ports for control | Stainless Steel |

| Gaskets/O-rings | Ensures final airtight barrier, prevents leaks | Rubber or Silicone |

| Ports and Valves | Allows vacuum pump connection and gas introduction | Integrated in Flange |

Need a reliable vacuum tube furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions like Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for controlled environments. Contact us today to enhance your research efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is a tubular furnace used for? A Guide to Precise High-Temperature Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the applications of a tube furnace? Master Precise Thermal Processing for Advanced Materials

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is the principle of tube furnace? Master Precise High-Temp Environment Control